I had meant to write at length about my table debate with myself.

I really want a flip table with storage at the sides, on casters and able to go to events.

Part of me, though, says “Just build something quick and get bootstrapped with that.”

I have too little space in my garage, so it’s always a struggle trying to fit everything in.

(10 pounds of Sh1t in a 5 pound bag…)

I have a number of scaffoldbench setups. This is a commercial product sold at the orange big box store in the US, which is both a baker scaffold and also a workbench/storage rack, cart. It has a pair of rails on the bottom of what would be a scaffold floor or workbench surface, and comes with some rails and holders so that tools can be attached. I have my chop saw on one, as an example.

The add on the big box website shows it like this:

The ones I have in my storage facility and garage are somewhat less clean and more cluttered.

[Side rant about stoage. In a sane world, I’d just have a bigger garage or buy a place with an out building shop. Instead, I have a stoarge facility nearly the same size as my 2-car garage.

I got the stoarge facility about 20 years ago, when I had a smaller house with a single car garage. I also had a little yellow carlson glasstron speed boat. Then I bought a share in a house boat, and a big ugly former airport flatbed service truck suitable to pull the speed boat and 7 days of supplies for 14-17 people. I started making task kits and moving things in and out of stoarge and staging them for work, fun, and making stuff. I’ve long since got rid of the house boat and speed boat, but I still have storage that I rotate things through less often.

Oh and everything everyone says about boats being giant holes in the water that you throw money into… they’re understating things.

/Rant ]

At any rate, there are two of these in my garage, plus a couple more that got converted into printer stand/print stuff organizers. Maybe I’ll talk about that in my V5 printer build thread.

At the start of the day, the back one looked like this:

The router table is just being stored there, it’s absurdly high up when mounted that way. Quite a tale, that ancient and barely used router table.

I decided to just go for a quick bootstrap table with whatever I had around.

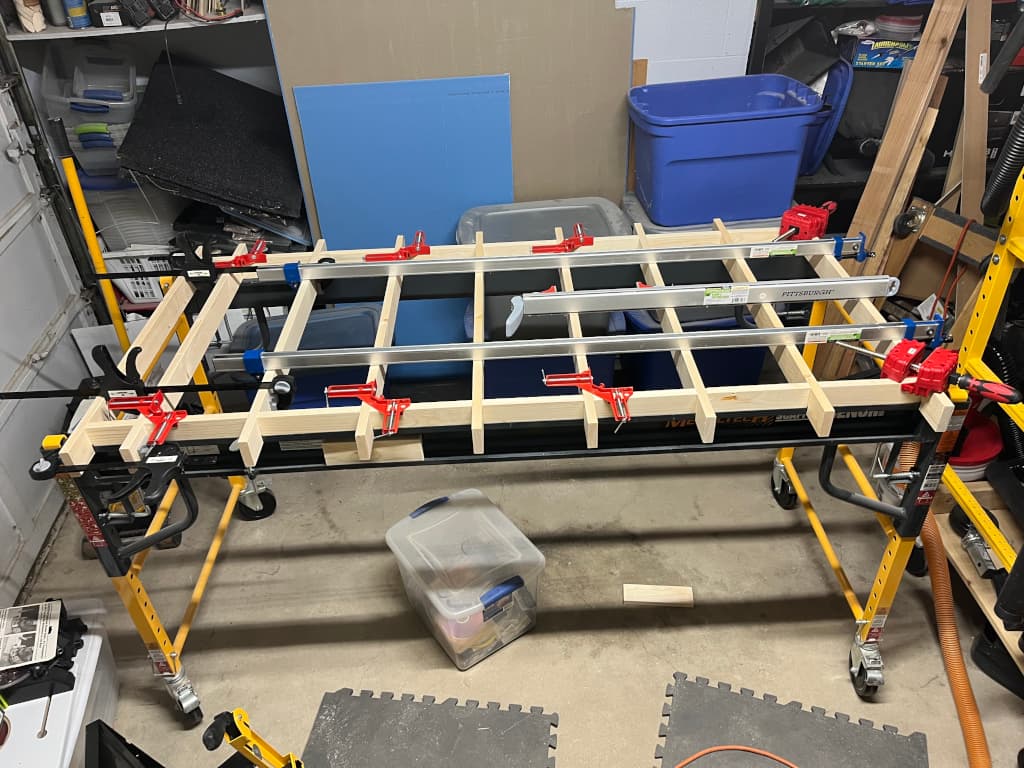

I had some extra 1x3 lumber from a different project, so grabbed a bit more, and off I go:

First step, cut a bunch of 1x3 parts to work on making a top for the table to mount the LR3 on.

Used the chop saw on the other scaffold bench, then a guide and a circular saw to cut a slot so these would clear the channel in the bench.

I had planned to make a sort of torsion box type setup, but realized I didn’t have nearly enough clamps (I buy clamps all the time, people think I have a clamp obsession, and still I never have enough clamps).

So this is what will dry overnight until I get back to it tomorrow. I made a bunch of 8" spacers and had planned to cut one small pair at the end, rather than try to get things spaced exactly even.

That leaves me with the rest of the torsion box parts. I might get ambitious and flip the top tomorrow, but it occurs to me that I may have accidentally made it adequate. It’s sitting on the steel baker scaffold shelf/work surface frame, so it’s well supported underneath. And the area where there are overhangs on either side has the spacers installed. Hmmm…

But I would have to find a use for all those 8" 1x3s.

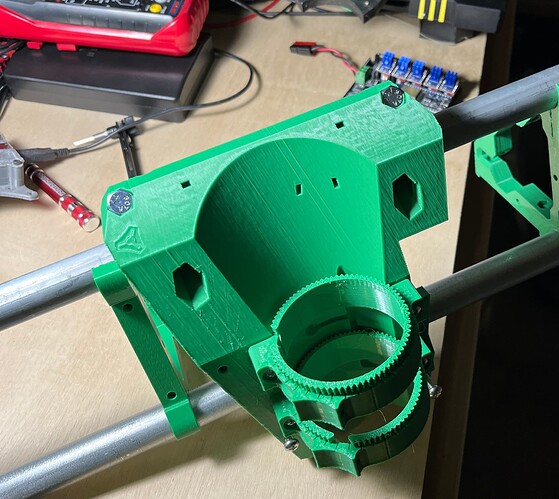

Pardon the mess. Many random other project remnants, including the DIN rail I’m going to use on my V5 repeat printer making a cameo.