OK, well it’s time to get a core printed.

The core is too big for the FFCPs.

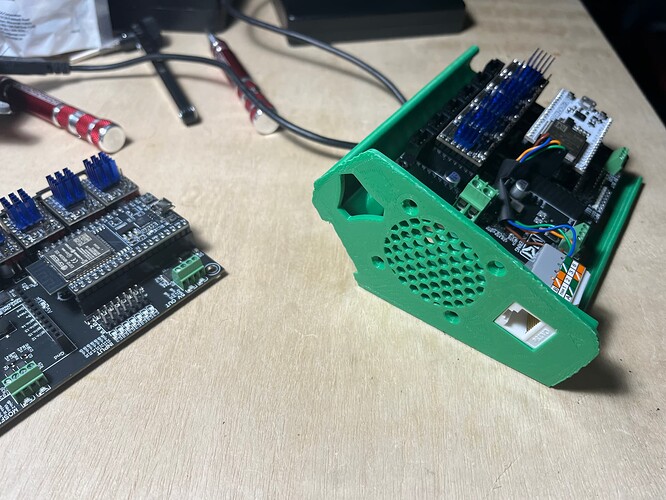

So, time to dust off the TAZ5.

I had put a giant 1.2mm nozzle on the Taz because I was printing some special conical tree starting tubes for a local nursery. Interesting story if anyone wants to hear it.

You can kinda see one that failed sitting on the table.

Single wall, ,vase mode print 1.4mm thick tglase material. I printed a hundred of these, saved them an immense amount of money for their little science project.

At any rate, had to swap back to a .6 nozzle, do some bed leveling, and a little tuning.

You can see over on the right I have a tool head that has a digital dial indicator. Incredibly useful for leveling an old dinosaur that only has a single bed level microswitch and 4-point heated bed mount.

It’s really easy to swap tool heads out on the TAZ. One thing I’ve always liked about this printer.

I’ve been using PrusaSlicer and CURA with the TAZ and streaming with one of my OctoPrint Pi 3s.

I updated PrusaSlicer on my Linux box and poof- no more profle. So Cura it is for now. .3mm layer height.

That kludge table is made using parts of baker scaffolding- more about that later when I talk table.

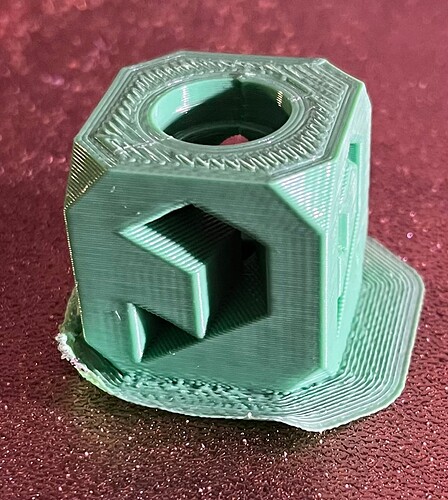

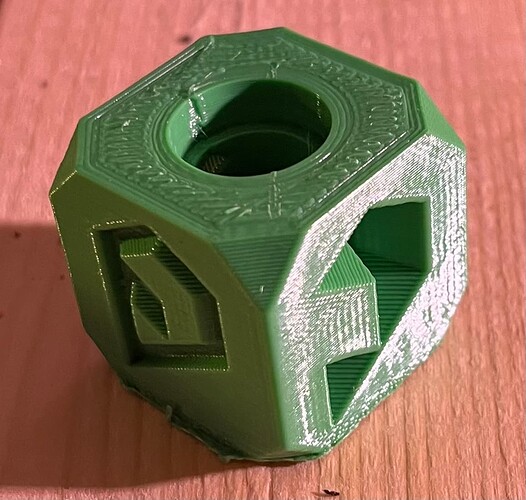

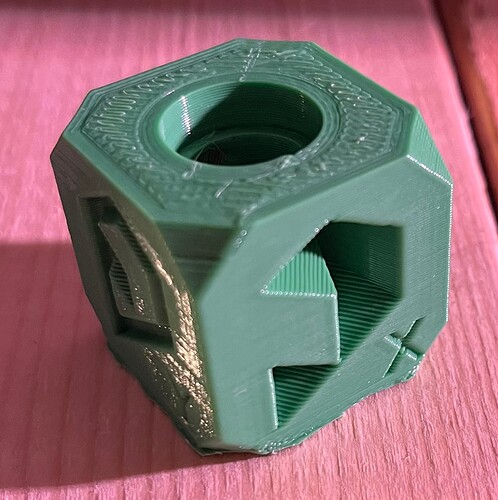

First test calibration cube- bad first layer height, slightly overextruding. First layer and first layer brim speeds way faster than my textured PEI likes it. So the brim curled up. The test cube turned out OK, overhangs and all but the internal heavy bridge test- which was not great.

(The bridge wasn’t terrible, just not great)

Honestly, not bad for a 9 year old printer with many thousands of hours on it.

Rambo board, Latest marlin (DrunkenOctopus), my own hack job of a tool head and a PEI magnetic bed.

If the re-print of the calibration cube looks a bit better I’m going to go for the core.

Cura is projecting an 11 hour print to knock out a core. Octoprint usually runs just a bit longer.

ArcWelder makes Octoprint only slightly slower at runtime compared to the Cura prediction.