I cannot tell a lie, I was beginning to doubt whether the silver and cream was just too conservative, but the vanilla white Prusament is splendid, and even if the thing doesn’t go, it makes a lovely workshop ornament.

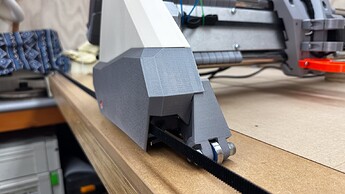

The fenders fit perfectly and really look to be part of the machine. (well one does - the other comes tomorrow)