Back in the swing of things after a week of doing not much but catching up with friends in various parts of the country, and somehow all non-build-a-cnc jobs have multiplied while we’ve been away!

On the face of it I could have the machine running over the weekend, and I was going to do that and build a temporary table to check out how my vac hose thoughts would work out. Instead, I’m going to launch into the final table top and a few other jobs while I’ve got the tablesaw clear.

It’s odd documenting stuff “as I go” because there’s no room for error - but it’s nice to have people to cry with when things go wrong.

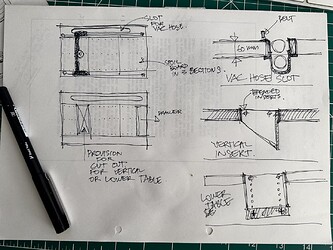

Here’s the plan:

I’m going to build a “proper” torsion table 60mm thick with 3mm skins because all the benches in my shed are the same height, and that’s how much depth I had for the LR2 (with the max 100 thickness) and I’m not going to re-build the platform on which it sits.

I’ll incorporate a drawer in one end, and with some reservation “make provision” for a cutout in case I ever want a deeper table or to mill the end of a vertical drawer or something. I won’t build it, just make a gap to be cut out later, and locate the threaded inserts.(t-nuts)

The reservation comes because, long before YouTube was invented, I did something similar on my drill press table and it’s been used exactly zero times in the intervening period, but it’s a handy storage spot for the vice.

The spoil board will be in three parts, because the home corner is going to be much more likely to need replacing before anything else.

The vac hose will run in a slot built in. In reality this costs only an inch or so and will just make it tidier and a little protected against pushing against the wall - I may or may not add printed brackets below so the hose can run back on itself and stay off the floor.

Questions and specially criticism will be welcome - construction may start tomorrow!