I have no idea what time it is for you, but since you are up so late (or is it early)- here are some I prepared earlier - I’ll save the text till the end so you don’t get distracted by the photos! I think it’s all smacks a bit of a '60’s Vespa in this livery! ![]()

Yes that is the final top, and no it’s not the final colour even though it does look strangely stunning!

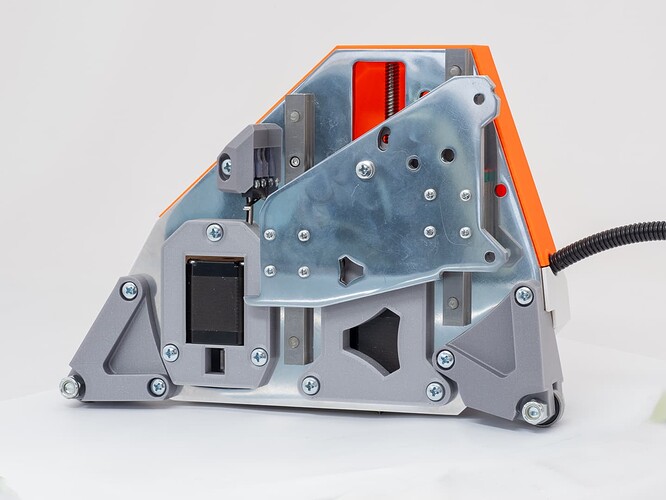

I printed in orange because I’m going to paint the top part and I am a bit of an advocate for the “cut watermelon” school of design (which I may or may not have founded), but which says that sometimes it’s nice for a cutout to be a different colour. just as when you cut a green watermelon you are met with a sea of red - here, the little glimpses of view inside will be met with a flash of orange in contrast to the silver exterior. (wish I’d cleaned off my fingerprints!)

The original plan was for a slightly off-white with polished struts, but for now I’ll paint it silver to match the “temporary” silver hardboard ones. It’s only paint so we can always change it.

The bottom panel will be in galaxy silver for now, but goodness it looks stunning in the photos as is! Don’t forget though, we are viewing this in isolation - it will shrink somewhat when the rest of the machine is attached.

The badge, for reasons explained earlier - won’t be there at the end although I am tempted to pull out the .25 nozzle and try a smaller one.

It’s printed in Quality mode at 0.2mm layer heights and while it did take a while, it’s a beautiful print and wont’ take much paint prep at all. Here’s hoping I can get a perfect bottom layer for the silver bit as well.

Ahh Jeff, where did I go so wrong? ![]()

![]() I told you I will never forget that quote!

I told you I will never forget that quote!