A week or so down the track, and the plates are all happily sanded to 600 grit, waiting for me to pluck up the courage to take to them with the router to chamfer the edges. In my defence a few days off with a heavy head cold after a few days off visiting grandchildren has also contributed to the delay there.

On the printing front, another day or two will see all the parts completed. I did start to do a complete comparison of perimeters, nozzle thicknesses and so on just for fun, but given that there is such a wide variety of speed capability with modern printers and the reduction in print time is pretty linear - increase layer height = decrease in print time, that it seemed pointless.

On the other hand the difference in filament used is also trivial.

In one of the few areas in which I’ll divert from the company line - I’ve used 0.4mm nozzle, 0.2mm layer height and gyroid infill at the specified densities. I have also used 5 perimeters (2mm wall thickness). I believe this will provide more than adequate stiffness for my use albeit at the cost of a lot of print time!

I print one part at a time, because time isn’t important, and start a fresh spool with the largest items to prevent any accidental conniptions with running out of filament 26 hours into a print!

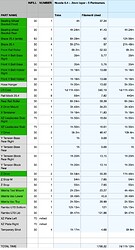

Here’s a summary of my standard print times - PrusaSlicer 2.5 printed on a MK3s (I expect the Ender and other first gen bedslingers to be similar). Green cells are complete.