Hello, V1 Engineering Community!

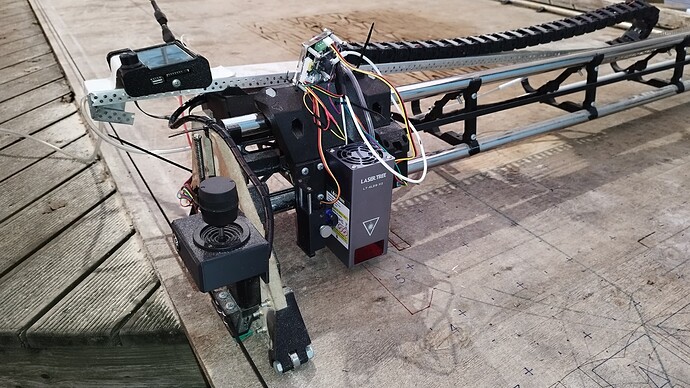

I am thrilled to share with you the journey and creation of my latest endeavor: a custom-built Lowrider3 CNC machine, boasting a vast working area of 5800x1625mm. This machine is not just remarkable for its size but is equipped with a servo pen, laser, and joystick, providing unparalleled flexibility and precision in my projects.

Purpose and Vision

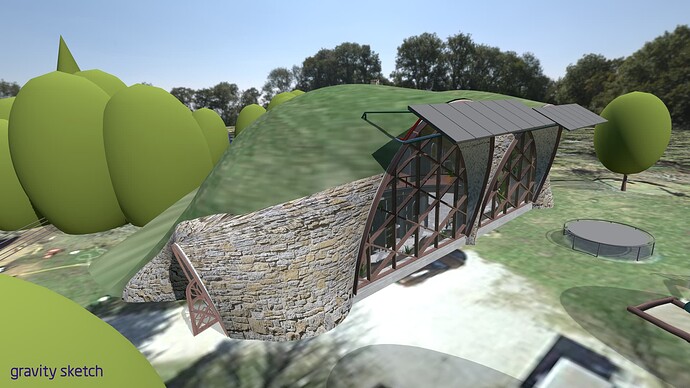

The primary mission behind building this machine is to support the construction of my earth-sheltered monolithic dome home - an eco-friendly and unique dwelling focusing on low-tech and off-grid solutions. This home is designed to harmonize modern design with sustainability, utilizing recycled materials and leveraging natural properties for thermal regulation.

Why This Project?

Believing in a living environment that complements nature rather than competes with it, my dome home is conceived to integrate earthship characteristics with thin-shell concrete dome techniques. This combination creates an energy-efficient, durable, and visually striking habitat, marrying my passions for invention, architecture, and sustainability.

The Machine’s Role in My Vision

The Lowrider3 CNC machine is a cornerstone in realizing my vision. Initially, it will be used to create the airform necessary for constructing the dome, a critical step in the building process. Later, it will serve in crafting furniture, doors, windows, and other essentials for the home. The machine’s versatility and accuracy allow for the execution of complex designs and custom adaptations as needed.

Integrating Advanced Technology

For preparing G-code, I’ve utilized LightBurn software, for which I developed a G-code post-processing script. This script identifies the layer designated for the servo pen, adjusts for the pen’s offset relative to the laser head, and converts M3 commands for pen lowering and M5 for raising. This innovation enables the simultaneous use of two tools, enhancing the machine’s functionality.

I found the means to connect both the laser and joystick through this very forum. The pen’s servo is attached to the BLTouch output, demonstrating a creative adaptation of existing components. The machine’s frame utilizes 25mm tubes, originally curtain rods, chosen for their lightweight and sufficient strength. This choice highlights my commitment to resourcefulness and adaptability.

A Note on Aesthetics and Progress

It’s important to mention that this machine, while functional, is not the prettiest—you might say it’s a work in progress. My focus has been on functionality and innovation, ensuring it meets the needs of my unique project. I view this as an evolving tool, one that will improve and change as new ideas and feedback are incorporated.

Equipment and Design

For laser cutting, I’m using a LASER TREE LT-4LDS-V2 20W model, capable of cutting through 6mm birch plywood at a speed of 2mm/s. This tool was instrumental in creating my “Strutplates” with precision and ease.

I designed the servo pen mechanism myself, which can be seen here on TinkerCad: Servo Pen Mechanism.

The joystick design, another personal creation, is shared here: Joystick Enclosure Design.

Engaging With the Community

I am eager to share thoughts, receive feedback, and exchange ideas and experiences with you all. Any tips, ideas, or experiences you’d like to share, particularly regarding large CNC projects and unique material processing, are most welcome.

Thank you for taking the time to read about my project, and I look forward to our engaging discussions!