Long story short, I built a MPCNC Primo about 2 years ago. For some good and bad reason, I decided to convert it to LR4 since it was released.

Unfortunately, my space doesn’t allow me to make a huge surface. The cutting area is around 42" x 24". And even worse, for it to be pleasant to use, the X-axis needs to be for 42". So, the Strut Plates would be about 48-49". Therefore, it is impossible to produce them on my setup using simple techniques.

So, I started looking for solutions. I began by making a “temporary” version on the floor of my workshop, large enough to produce the Strut Plates. It works… but it’s really ugly to do. You have to set up a temporary rig, laying on the ground. Drill holes in your floor. Etc. And in the end, if you have to redo them, you have to dismantle your permanent setup to make a new temporary one. It’s a really bad idea.

I saw some video posts showing how to do it in 2 cuts by inserting a dowel as a reference point. Ok. That probably works. But, we’re starting to use more advanced techniques. A beginner who wants to build the machine with this constraint might not manage. This makes the machine less accessible, which I think is a shame.

So I wondered why the machine isn’t capable of producing its Strut Plates, regardless of the dimensions, by design.

I thought of 2 options. The first: separate the Strut Plates into 2 parts and make a joint in the middle. By merging two braces together, like this:

We could fix the two pieces and end up with a comparable structure. But would making the Strut Plates in two parts weaken the machine?

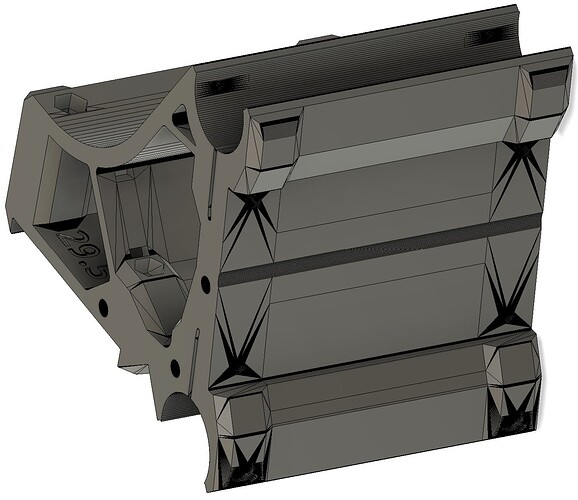

The other option I considered is making mega Min and Max braces that would start within the cutting area. Something like this:

So by design, the Strut Plates would always be shorter than the X-axis. I really like this solution! It seems simple and would make the machine even more versatile… However, would this affect the structure or rigidity intended in the design?

But above all, I wonder why Ryan didn’t plan for this? Is it a choice because it would interfere with the machine’s structure, or was it an oversight?

What do you think? Am I off-track with my solutions? Do you have any other suggestions to offer? Depending on your feedback and suggestions, I will decide how to proceed with the build.