My first version just had the 43mm hole, I think i have it somewhere. It’s not as precise though.

Really nice print sheet. Is it from the same make than Ryan’s?

And why two of each? ![]()

You can buy those on amazon / aliexpress for just about any build size. I have one for my 300x300 beds on the 2 MP3DP and one for my big E5 Plus at 370x377

They have them in several different patterns. Ryan’s is a custom made one. Keep saying I am going to email them for a quote for one for my logo but I haven’t yet. So afraid I would spend a bunch on it and then screw up and scratch it the first use ![]()

Maybe i do a second Lowrider ![]()

No, it’s not the same make than Ryans, they are widely available in stores now.

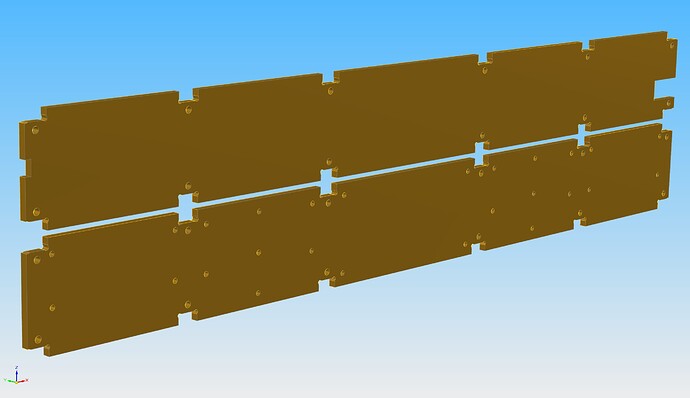

I designed the strut plates today. Since I’m also placing the electronics, such as the power supply, SSR, and DM542T, on the strut plates, and space is tight on my smaller Lowrider, I couldn’t make the distance between the braces even, so I couldn’t use the strut generator. I hope it fits and that I didn’t mismeasure anything.

You’re making great progress on the build!

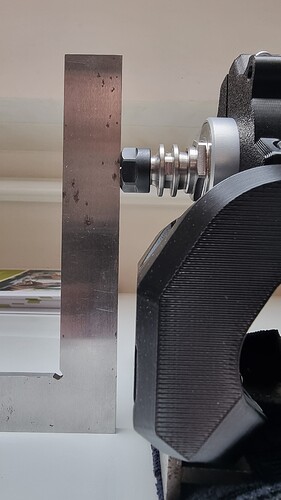

How far below the core should the tool holder be? Is ~5mm enough? I could lower the milling motor further by creating more space at the top, but that would require modifying and reprinting the core.

There’s no need for more - your collet nut should never come in contact with the top of your work.

I was just unsure if the distance might be too small it would be compatible with the dust shoe.

Is a 24V, 5A power supply is sufficient for 5 stepper motors. Are there any rules of thumb regarding the required current?

my lr4 kits came with 24v 2.5amps power bricks so, i think you are good to go

you need to measure if the tool holders wont crash with the core while performing the changes.

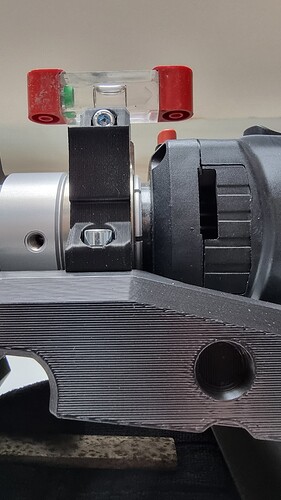

Just finished printing Philipp’s @Tokoloshe

bracket for my AMB mill. I also tweaked the core a bit to fit a lower tool changer. It’s printing now!

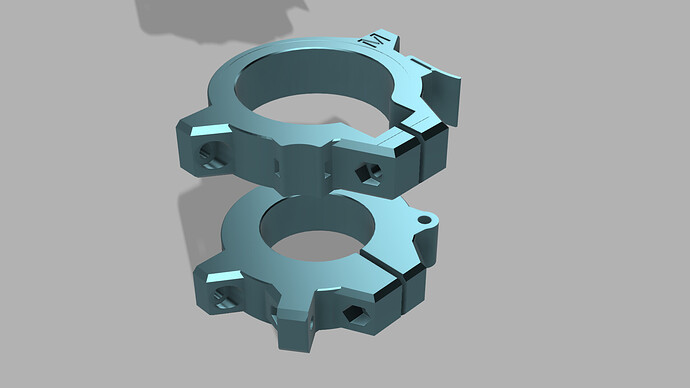

I don’t think my mount is going to make much sense with the toolchanger, does it? The bottom is just a circle for you, the top part should be different as well, it has recesses and bumps exactly at the spots where the router is at.

The AMB holder is for the second Lowrider that I’m building. I’ve already designed a holder for the tool changer, and it looks very similar to the AMB holder.

Could have asked, I had this already as well. ![]() Was the first version.

Was the first version. ![]()

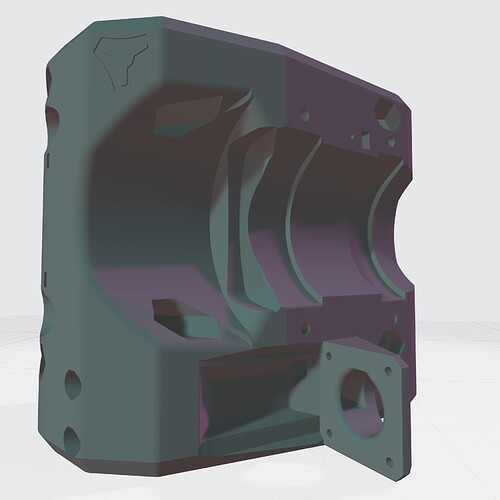

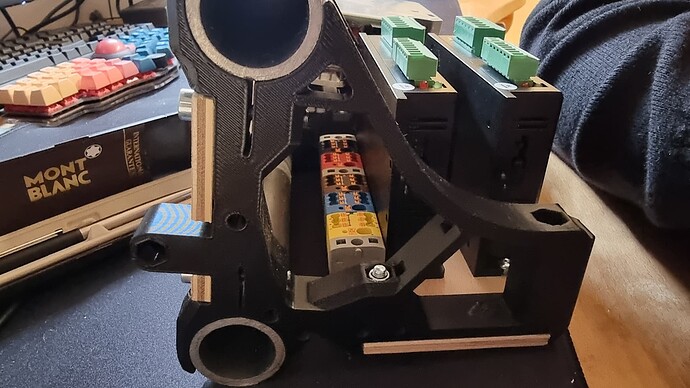

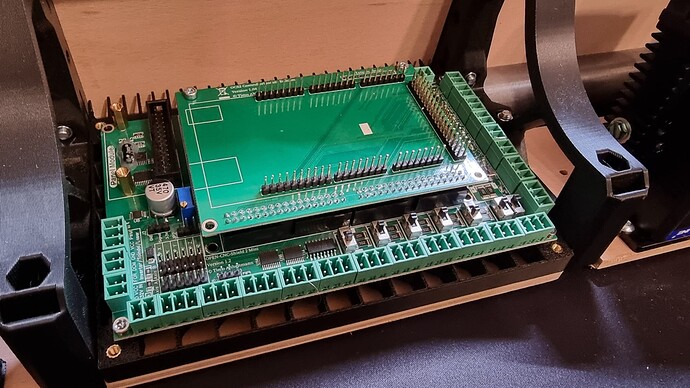

Things are progressing slowly here, but I have managed to finish the first two YZ plates of 4 and to mount the control unit, driver and the relay for switching the CNC spindle on and off on one beam. Everything fits just as I had imagined.

I hope that the cover from @DougJoseph fits to protect the control unit, if not I’ll have to do the work of constructing something myself.