… in progress …

pics or it didn’t happen ![]()

It will take some time, this is meant to be a build thread. I only started printing the parts today. I can already show a few photos.

Printing the braces

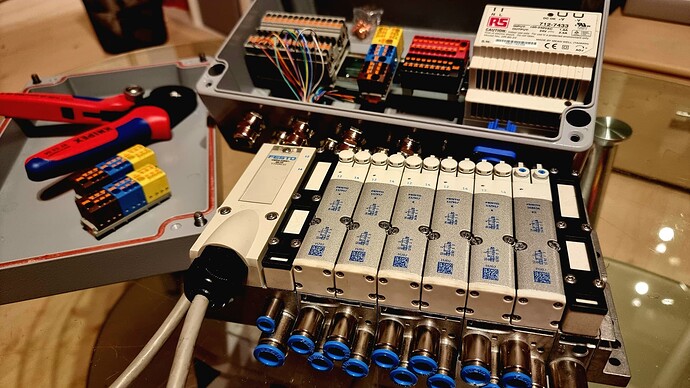

The control for the tool changer and vacuum table

Vacuum table and vacuum pump

Tool changer and spindle motor

Do you have a link for the toolchanger motor?

Builds in progress are the best ones!

I am also interested in the tool changer.

Toolchanger is from Stepcraft

But so far I haven’t had the chance to test it, I’ll have to wait until LR4 is ready. I hope it works as well as I imagine it will

Thanks for the link, the prices seems pretty expensive?

From what I’ve seen, that’s a pretty reasonable price for a tool changer.

I’m probaly just cheap!

Do you find that tool changer and tool changing is a large part of your workflow?

Kress have a quick release version, but these are brushed motors, i kill those a lot with acm. Going the spindle route better and a rapidchange atc

Kress has been AMB for a while. @Tobs_e used one before and I am using one now. They are pretty great. ![]() None of us have the toolchanger version though.

None of us have the toolchanger version though.

As i said the quick release version is more manual, but actually faster if you use a collar and a manual bit setter. Price aside im scared to run one of them and have issues with the motor later, i would have to import them to the us then manage to get it shipped to my country and thats kind of a hassle.

link-there is also a 1.4kw one

Maybe i will try one eventually, but fitting them to a LR is not in my set of skills ![]()

Yeah, I’ve got the 1400W ER16 version.

The problem with the tool changer is that you can’t really fix it to the LR since you have the lever to release the tool. I don’t see any way of making that work.

How that works for you? The spindle?

It’s great. You can see it in the Ghostrider thread and on my YouTube channel quite a lot. ![]()

Yes but the quick release version would be harder to adapt to a LR

That’s what I said. I’d nearly call it impossible. ![]()

Yes, im looking for a way to do quick changes between tools or broken bits (happens a lot depending on some materials)

Hey, whats your solution for mounting this spindle with the atc adapter to the lr4 core?

I would like to construct a fixture for this in Fusion. The ATC has a diameter of 43mm at the bottom (Euro neck mount, Philipp’s AMB holder could also fit here), the diameter at the top is 54mm.

But it will take some time, I just started printing the parts and don’t have the pipes and XZ plates yet.