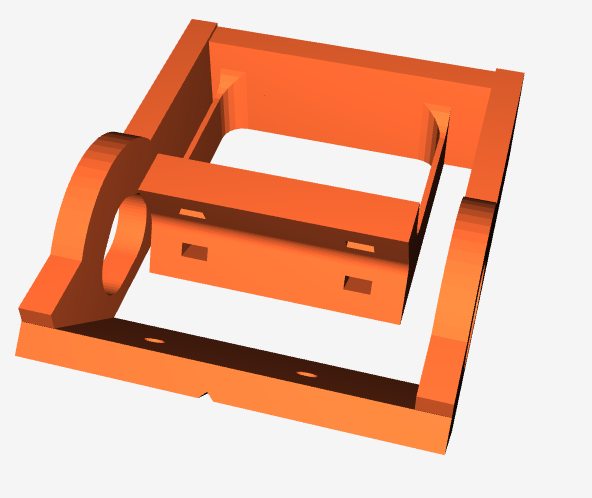

Ok I just added an “inverted” one too. (Same printables link)

I haven’t tried it but it should be able to hold the pen closer to the router. So you get back a tiny bit of Y range.

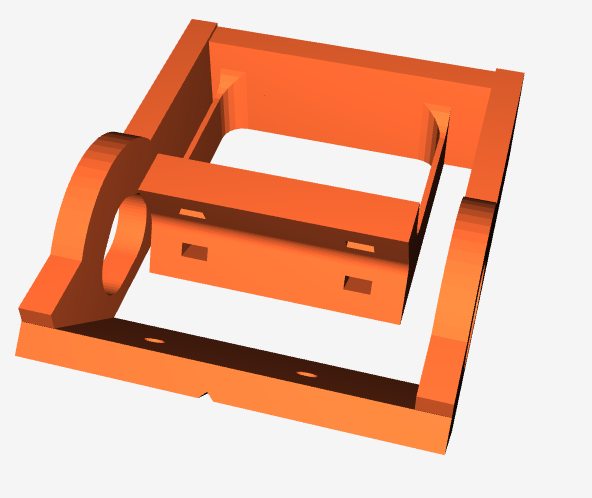

Ok I just added an “inverted” one too. (Same printables link)

I haven’t tried it but it should be able to hold the pen closer to the router. So you get back a tiny bit of Y range.