Doug that’s the same one I have on my full sheet machine. Idk how I ended up getting a different one on the second go around lol

@Jonathjon did you see the remix yet?

I looked at it from my phone real quick. Been a busy crazy day here in the ole wind farm. Way too many chiefs and no where near enough Indians. And the chiefs don’t have a clue lol

So I tried to put this onto my LR3 last night, and I couldn’t get the top screw to hold. It will come just to the back surface, and can’t grab the M5 nut with a 45mm screw.

That top ring is the clamp adjust for the router. Maybe my prints are off a bit, and maybe it’s a slightly different clamp.

So I remixed the main mount a bit to recess that top screw in another few mm, enough to grab the nut at least.

I am not sure that using the clamp surface is best practice if the mount has to be plumb. It seems to me that depending on that could result in a deviation from the desired angle.

Well, I’ll give my replacement part a try, but might end up with a different base part.

Are you sure it was seated all the way down inside? I’m perplexed. This is the first time I’ve heard of this kind of issue.

This is a valid point. I guess most of the tools that have been attached so far to my knowledge were not ones that would be bothered by the mount angle being off ever so slightly.

It wont matter for the pen or drag knife, but if I want to do any actual cutting with the laser, it will. I suppose what that means is I should make a laser mount that can be trammed. Insofar as I know, none of the existing designs out there account for this.

For engraving with the laser, it likely does not matter at all.

The nature of the laser does mean that there is always a slight cone to the focal shape. The people who cut my acrylic YZ plates warned me about this, that I should not count on the edges being actually square (though they are really close.) “Close enough” is still probably good enough, unless it is out far enough to affect actual cutting that I do. The only way that this would be a real.problem is if I want to do multiple passes at different depths. at the same depth (every laser job I’ve done so far) the laser will still follow the same path. It might not be plumb, but it will be consustent. It is only if I adjust the Z axis for successive passes that tramming might become an issue. I don’t know that I’ll ever do that, but something to keep in mind. Just saying it may be a problem for someone.

@SupraGuy — Good points!

Is anybody here using a neje laser with this mount? I get some minuscule wobble at higher accelerations and i’m not sure what could be causing i

Also the power supply i’m using seems to be kinda terrible, loads of ripple

How did you set up the magnet? If you are using a single magnet and a washer you might think about using 2 magnets. If using the same ones @DougJoseph linked then you will have to flip one of them. Not a simple task but it is doable.

LightBurn has a setting that allows you to edit the alignment offset for engraving at high speed. If the edges of the engraved lines don’t line up, this can correct it.

Some possibilities that occur,

One is that the LR3 core might not be gripping the EMT conduit tightly enough,

Another is that the kinematic mount might have something standing proud that is making contact before the mounds get settled into their grooves,

Another possibility is that an alignment is needed on the feed from the sender / controller, such as I mentioned in LightBurn above.

I’ll try the lightburn alingment tool, sadly I’ve just noticed my core has warped with the summer heat and is now rubbing the braces (this wobblyness problem pre-dates this issue but yet another thing to fix!)

The kinematic mount itself seems very rigid so I don’t think it’s that

What a cool idea! Love the concept, as well as Jamie’s remix. Thank you all for the effort. I will definitely add this to my LR3, but I expect that I will find many other places to use these.

I remixed the remix with a minor addition. I added a 2.5 mm hole through the “valley” mount for an M3 screw to hold 1 or 2 washers. I used these screws: McMaster-Carr and these washers: https://www.mcmaster.com/91090A104/.

https://www.printables.com/model/648809-modified-kinematic-mount-valley-side

Yes, this is my first post here. I have an LR3 hardware kit in the shop and a Kobalt router for it, I have a lot of 3D printing to do before anything gets done though.

Re: that probe, yet another use for the LR3, a CMM! Coordinate-measuring machine - Wikipedia

Downside is that the software for these is usually incredibly expensive… (at least it was last I checked years ago.)

Well, I’m disappointed…

While the mou t feels,solid enough, and I am not complaining about the drag knife performance, its performance with the laser isn’t nice.

The problem appears to be that it shakes.

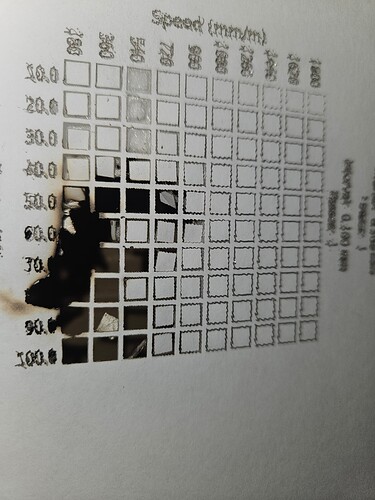

Given recent history, you’d think I’d be more careful with material tests, and my first ones were, but I needed to slow things down because shaking. Even here, once you get to 720mm/minute, the shaking is clearly visible. Basically the laser gets to be too squiggly before the percentage range gets useful. Maybe I can do something with lower acceleration limits or something.

This was the first connection of the NEJE E40 laser. I had the A40640 before on the LR, but never did get the air assist working. It works on the E40.

I had a heck of a time getting usable Gcode out of Lightburn. RepRap Firmware doesn’t really like it’s Marlin output, complains about a bunch of invalid stuff. At first, it wouldn’t turn the laser on at all. I could manually enter commands in the console that worked, but as soon as a LB program started… Nuthin. Finally figured that out. (Apparently theast time I had a LB program thst ran on the LR was version one point uh-oh.)

Well, now to see if I can figure out a way to stiffen the kinematic mount, or if I need to go back to the drawing board for a laser mount.

Don’t be. You have done a great job in reaffirming my decision to buy a complete machine!! I suspect that having done that I have half a chance of having slightly less trouble getting up and running, but I am so happy to be able to feel your pain vicariously.

It makes me feel alive! ![]()

![]()

Well, FWIW, Ill be building a new dedicated machine. The Bart Dring 2209 board survived, or at least I think it did. The stepper motors are.OK, but the wires are done. (If the stepper wires shorted, the 2209 drivers might not have made it, even if the ESP and rest of the board did. Then it may be Jackpot time…)

I am confident that a better mount would solve the problem.

Oh, and I figured out why the percebtages all look awful. I configured my firmware for a 100% value of 255, and LB wants 1000, so anything over 25% was actually running at 100%

A max speed of 500mm/minute is OK if I can get a reasonable range from marking to cutting. I’m going to try another material test pattern.

So sorry. No doubt the initial part that connects to the LR3 is the weak link. I will probably go back to the drawing board. But I want to actually connect a laser to mine, and do some testing. I am astounded at this.

Bummer that you had issues.

This max power definition seems to bite a lot of laser users, on various firmwares. It seems to be a common mismatch.

That rate equates to only 12 mm/s. I could imagine a little bit of flex when changing direction at the end of a raster pass, but it’s baffling to imagine that it’s wobbling that consistently across an entire raster pass or at all. Was this raster work? Or was it attempting to cut straight along each vector? Either way that amount of shaking is astounding. Can you confirm that rate was per minute and not per second?