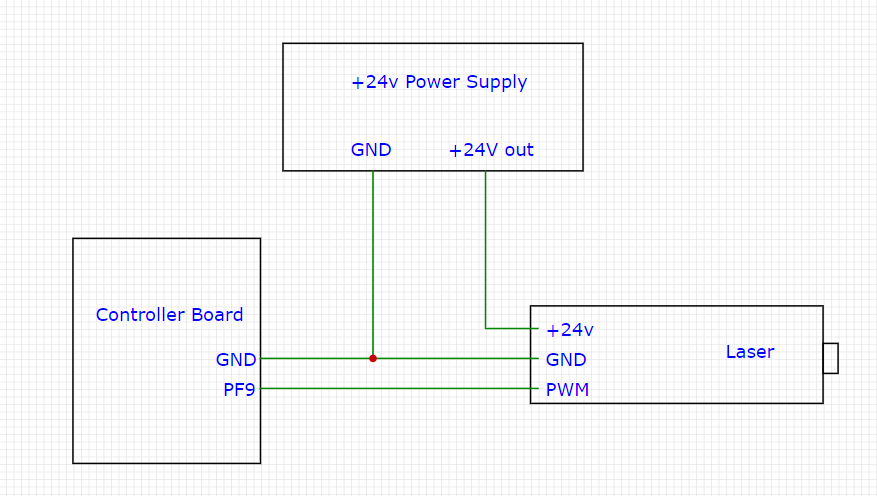

Before I comment on your post, let me suggest two things. First, you use M3/M5 on the new board to control the laser pin to see if you get variable voltage. You want to do the reading immediately after sending the first M3 since the safety disconnect will kick in after one second. Second, if you are comfortable with the electronics, you could just try the new board and PC9 to see what happens with the laser.

As for the M42 commands, I’ve never figured out where Marlin maps g-code pin names (and I’ve done a bit of looking). Since I don’t own an SKR Pro, I cannot test the naming for this specific board. Given the labeling on the pinout, I would think the pin name is ‘PF9’, so the command might be:

M42 PPF9 S128

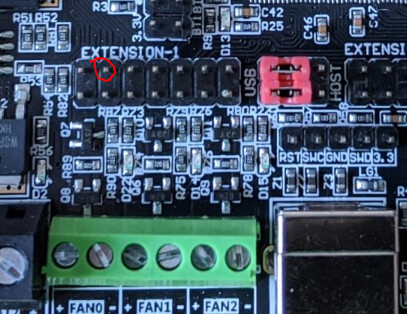

You are in a position to run a name test. No matter what kind of pin you have (PWM or not), Sending an S255 should give full voltage, and there are 11 other pins on extension-1 you can test.

In addition, if you’ve assigned PF9 as the laser pin, I’m still concerned that M42 might be ignored if Marlin identifies the laser pin as a protected pin. M3/M5 should work on the laser pin, though there is still the safety disconnect to consider.

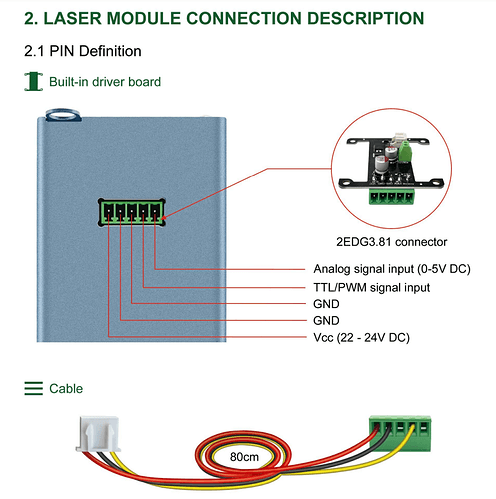

In general, you are right with the voltage assuming these are 3.3V pins and assuming you are using the V1 default firmware. The VCC on Extension-1 is labeled at 5V, so I would assume the other pins on the block are 5V pins, not 3.3V pins, but I do not know.

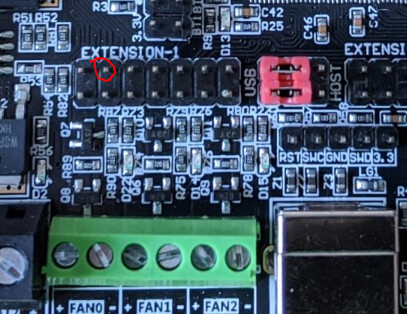

Hopefully others on this form are still following this topic, so you should get a picture of a laser hookup. According to the pinout diagram, the pin I’ve circled in red is PC9, and all the grounds are tied together, so you can use any of them, including the one adjacent to PC9:

Reiterating something I indicated above, M42 worked fine on the laser pin on version 113 of the firmware, but I’ve not tested on the rewritten 115 version, and I’m not home to run a test on my machine.