I have not yet had a chance to check, but I will.

Love the video! That’s so cool that you have a working setup!

I’m still trying to get my steppers and end stops wired up, correct and working. I have yet to see a sign of life in my build!

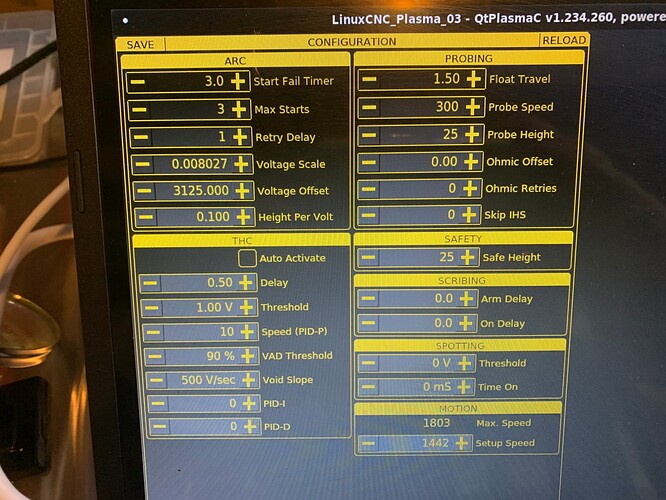

No, as far as I can tell, the values in QTPlasmaC ( Parameters > Configuration > Arc > ) Voltage Scale and Voltage Offset do not match values I got from Kyle’s calculator.

I’m not sure which to go with. If I want to try to go with Kyle’s calculator numbers I guess I would edit that in the INI file. ??

Below is a screen shot from QTPlasmaC.

Note: at the time when I ran the LinuxCNC PNCconf wizard, it was not yet updated for THCAD2, so I had to go with model = 10, but since then a guy on the LinuxCNC forum informed me that he updated it to have a dropdown choice for THCAD2.

Also, at the time when I ran the LinuxCNC PNCconf wizard, it was not yet able to accept any 0V Frequency (kHz) lower than 100, and my THCAD2 says 99 on the back. So, I entered 100.

The difference between 99 and 100 affects the results of Kyle’s calculator slightly.

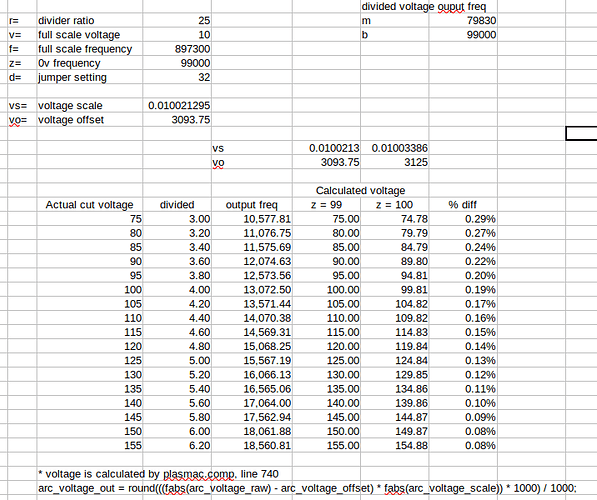

Kyle’s calculator, for my setup, with 0V Frequency (kHz) set to 99:

Scale: 0.01002130

Offset: 3,093.7500

Kyle’s calculator, for my setup, with 0V Frequency (kHz) set to 100:

Scale: 0.01003386

Offset: 3,125.0000

Still neither of those sets of values matches what QTPlasmaC is showing.

I barely understand how this works but I would venture to guess that is close enough. It is in the end a pid so it will keep moving until it finds the target. As long as they are close it will get there either way.

Most import are the Z speeds and accels, and what I think did wrong, is went too conservative with the Z values. The faster it moves, the faster it gets to the target.

Agreed!

FWIW, I don’t know if this is still the case but in the early days Phill strongly resisted putting a calculator in plasmac. He advocated that people should measure actual voltage with a multimeter to calibrate their raw voltage reading rather than rely on the numbers on the sticker. And the should be running test cuts on the material they intend to cut and find what voltage set point works best for them rather than relying on plasma machine mfr cut charts.

I’'ll try to take a look at my dip switch settings on Monday but I’m not sure I’ll be able to get to it to see it in the case.

That is interesting. I guess I could try taking a reading. I wonder how close it is.

Hey, quick question for @vicious1 or @kd2018 or anyone familiar with QtPlasmaC.

On the short test vid that Ryan posted (copy below) his “jogging” buttons near lower right corner are “lit” in yellow (until he starts a cut and then they go gray).

I don’t have all my motors wired yet, but I thought I would wire one and test it, but my “jogging” buttons are grayed out (all the time, even while not doing a cut).

Is it this thing where they stay grayed out until I get them all wired up?

Somewhat related, I saw someone mention testing a stepper motor during the PNCconf wizard, using a “test / tune” option, but when I click that option I get a dizzying array of dialogue boxes and I cannot for the life of me figure out what to press just to get a motor to move (providing wiring is all correct).

You have to home before you can use them.

That is what I remember from that as well. I saw a screenshot of a super easy looking interface but I remeber getting something wild. Still crazy weather here so I can’t mess with it.

OK, thanks! I will keep wiring up motors and hopefully when I get done I will have a testable setup without a bunch of reworking required! I am just nervous that I’m not doing it right.

My concern is not that I will get one wired 4321 instead of 1234 – my concern is that I might accidentally get one wired up as 1243, or 2134. What happens if instead of - + - + I wire one up as + - - +?

UPDATE:

Got the answer from @jamiek over here:

Here’s a full quote:

Hooray! Got my first signs of life with my plasma CNC stepper motors!

I’m testing out motors without my belts (X and Y) hooked up. However, my lead screws are connected.

It seems my X is wired correctly and running right! My Y motors and Z motors are not running right. But I’m finally to a point of seeing movement and troubleshooting where I’m not!

No. In our simple configurations LinuxCNC doesn’t have any feedback from our steppers to know if anything is even plugged in. As far as the software is concerned it’s going to send output signals to the mesa card whether anything is plugged in it or not.

I believe the jogging buttons will stay greyed out until all the “joints” that have been configured in the ini file have been homed.

Thanks for the help!

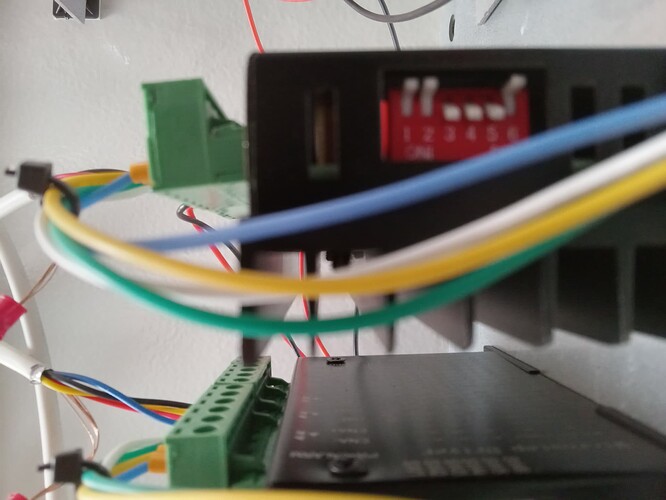

Regarding the dip switches, the only difference I see between yours and how @vicious1 has his, is you have 4-5-6 as off-off-on for 2.8 amps, while Ryan’s are off-off-off for 3.5 amps.

I’m plodding on with getting all my movements and homing working.

I just double checked mine are set at 1A, that pic I sent is old.

OK, I guess with mine still matching your old pic, I’d better reduce how much current I have running.

MILESTONE! Got all the axes homing, including dual Y and dual Z homing and endstops all working correctly. E-Stop switch works, Float Z switch works, all motors work, and all endstops work!

Note: Of the various minor issues I had to track down and fix (on wiring: one failed solder joint, one loose connection, etc) there was one issue that was software instead of hardware. I inquired on the LinuxCNC forum and got the answer super fast, very first reply, from Tommylight, one of the mods there. Here’s a link to the thread where I described issue, got help, and it was the solution:

Dual Z issue with tandem Z: wiring seems fine, but no movement

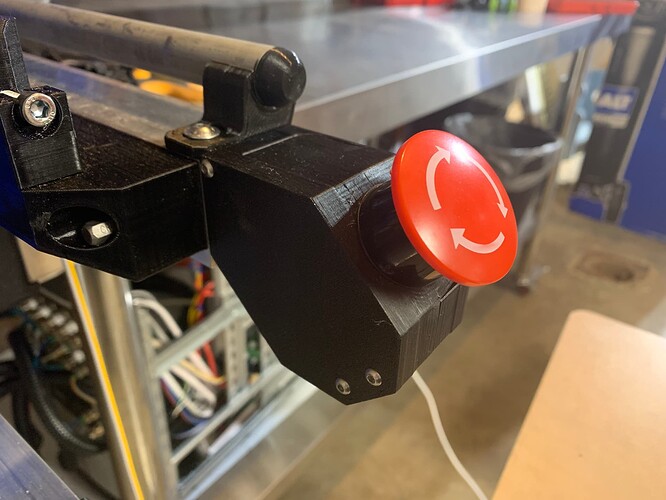

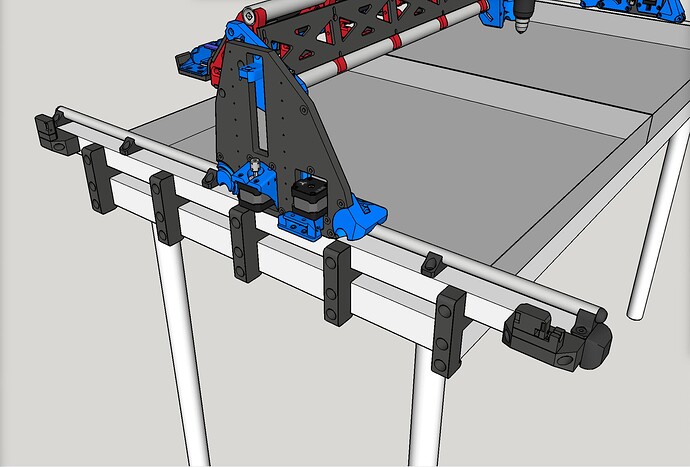

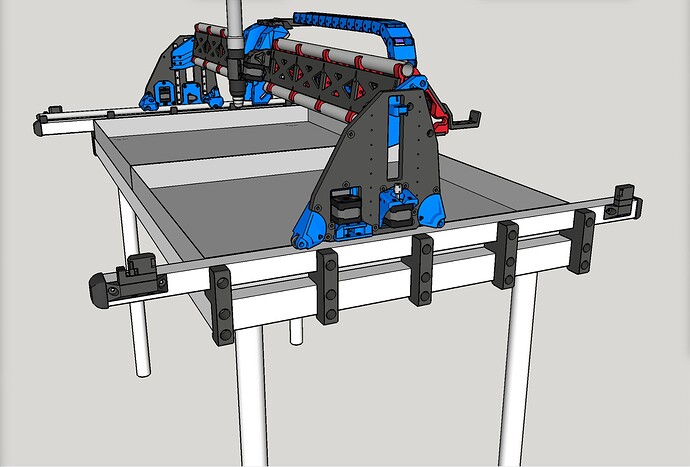

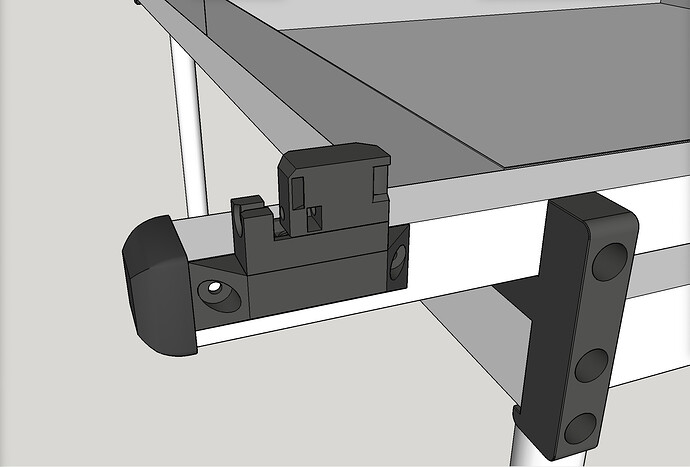

Several of my designs (and some remixes) for my CNC plasma rig are available here for free, and several others are exclusively for supporters on Patreon that support me for any amount, even if only a dollar a month. https://www.patreon.com/design8studio

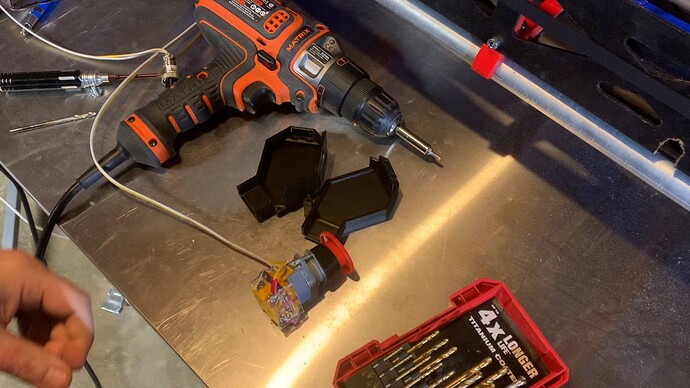

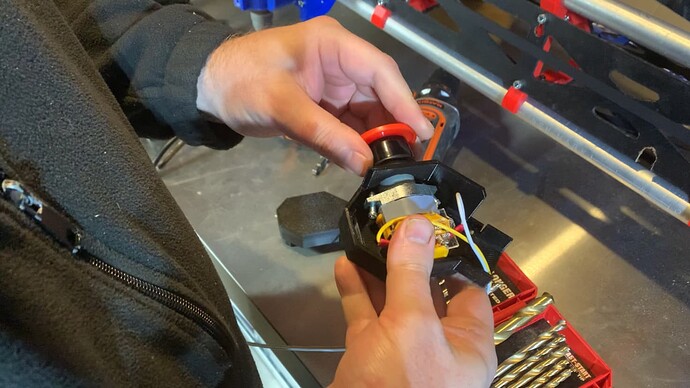

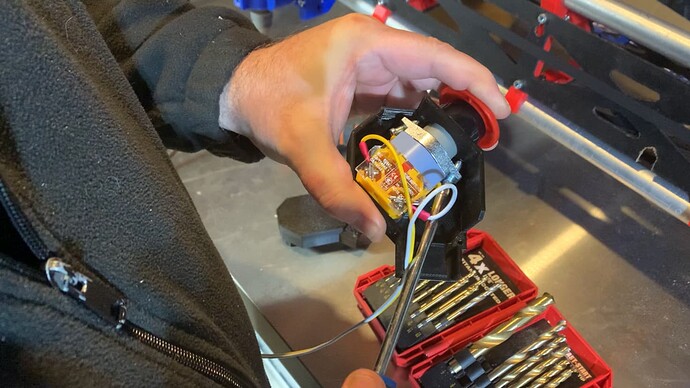

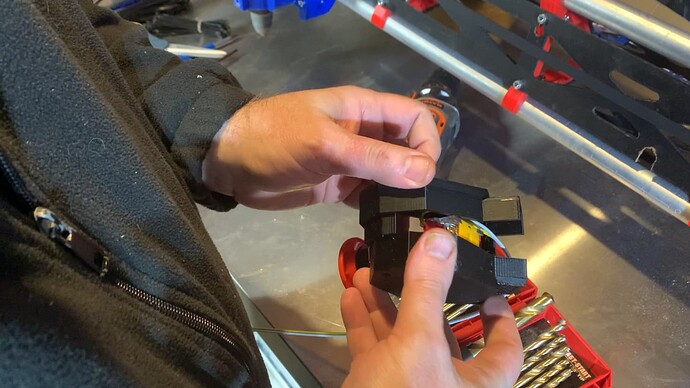

Speaking of which, the mount box below is one of the items available there.

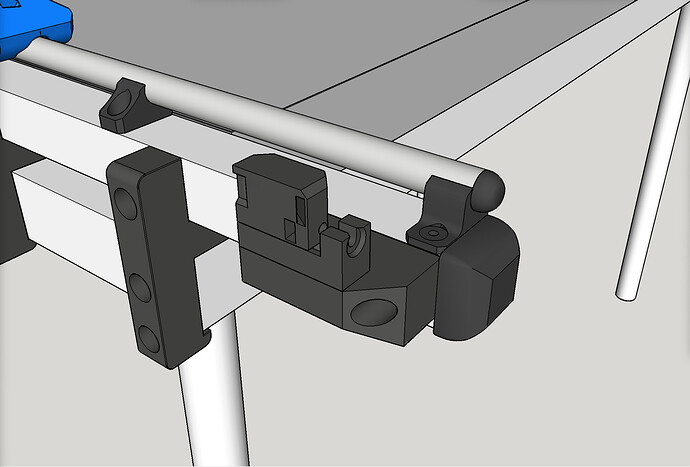

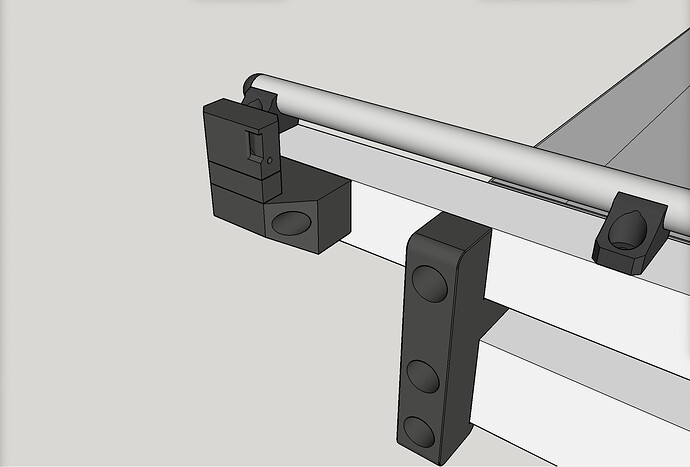

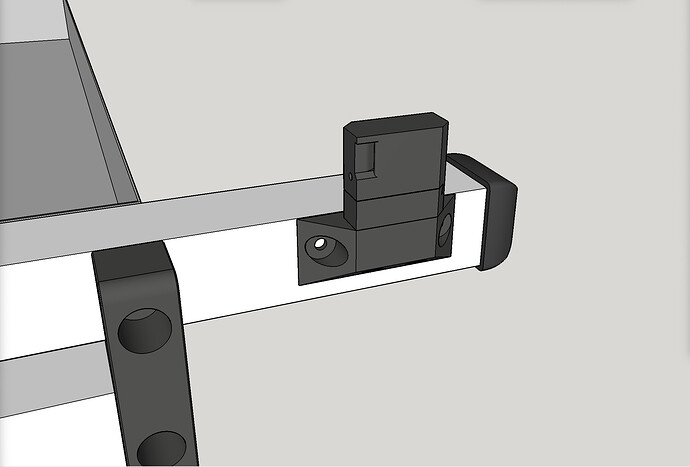

Several of my designs (and some remixes) for my CNC plasma rig are available here for free, and several others are exclusively for supporters on Patreon that support me for any amount, even if only a dollar a month. https://www.patreon.com/design8studio

Speaking of which, the table extenders below are among the items available there.