I wouldn’t go any thinner than 8th inch. Unless it’s a really shitty piece of steel, it should be just as flat as a 3d printed part, or plywood.

The cut XZ parts that V1 1is selling are 1/4 inch. That will be plenty in aluminum or steel.

I just got a price for cutting with laser in steel and it´s close to the cost of printing them  . Should I keep the thickness of both plates the same in 1/4"/6mm, or would it help to have the YZ stronger? Lets say 5/16" / 8mm or even 3/8"/10mm?

. Should I keep the thickness of both plates the same in 1/4"/6mm, or would it help to have the YZ stronger? Lets say 5/16" / 8mm or even 3/8"/10mm?

1/4" steel is going to be more than enough, and at that point, we might want to start saving weight.

If you do the YZ plate in steel, you’ll want the dozen small holes for the linear rails tapped for an M3x0.5mm thread, and substitute in M3 screws for the #4 screws/. (Well, I suppose that you might substitute in a #4 machine screw thread, but I’d go with the M3.)

Quick question- is ‘Z drop’ on stepper power off still a thing on the LR3? Still recommended to ‘park’ the core before power off?

Thanks

Short answer: yes.

Still doubting if I´d make an LR3, so was making a wishlist of 3D parts I needed and ran into some questions;

-

for a full sheet (2,44x1,22) I´d need 8 braces / hose hangers, right? And will 14 rail blocks be enough?

-

there isn´t any infill noted for: “leadscrew stub”, “SKR case”, “TFT case” and “Makita 700 series perpendicularity tester”. Is this 30% too?

-

Does one need the TFT case “clip” too to mount it on the SKR case?

-

The “Makita Vac mount” lists that it is for “~48mm OD Vacuum hose”. The LR 2 had one for 38mm. Is there a version available for the 38mm hose so I can keep my current vac hose?

thanks

Yes, info added.

Info has been added to the stubs, 70%. The cases and makita are thin walled infill doesn’t really matter as there typically in none, or very little. I will add some notes for 30% just so the info is there.

I am making a note to make an adapter.

Thank you for fining all the holes I am leaving. The docs are getting very complete.

I just sketched up a little tube that fits snugly into the DC end, and that my 38mm hose from the LR2 fits snugly into… Now where did I put that file…

Vac Adapter.zip (26.7 KB)

Edit: this part definitely has an “up” and “down” – the part is tapered so that it gets tighter as you push it into the DC, and also so that the hose gets tighter as you push it into the adapter. It works well for me, as I have a smooth walled end that just fit over the LR2 part.

Thanks guys!

I have no knowledge of stepper motors and I´ve been wondering how would the recommended STEPPERONLINE 17HS19-2004S1 motors compare to LDO-42STH47-2504AC that Ratrig sells.

I’m no stepper expert, but comparing the STEPPERONLINE on Amazon vs the LDO from RatRig, I find the LDO to be more expensive for less holding torque. In addition, the LDO has a higher current per phase rating meaning you may have to run it below it ideal current settings with some of the common internal drivers like the A4988.

Does it mean the LDO motors are more expensive and less powerful? I guess I´ll stick with the recommended ones.

Just curious about printing correct sizes for 25mm piping. Looks like there is 25mm brace file but for rail blocks, there is only 25.4mm file. Is that correct? Why are braces exactly 25mm but blocks are 25.4?

Have another look, they are there.

Whoopsie. I first deleted the sizes I wont need to avoid confusion. I redownloaded it and found it. Sorry. And thanks!

It depends on which LDO motors you get. My printer uses their motors, and linear rails. I have no idea who made the steppers I use on my mpcnc or lowrider. I’m prettty sure I got them both off amazon and just went with what was closest to the spec Ryan uses.

This is LDO’s stepper of the same spec. 42STH48-2504AC They’re $18 at filastruder.

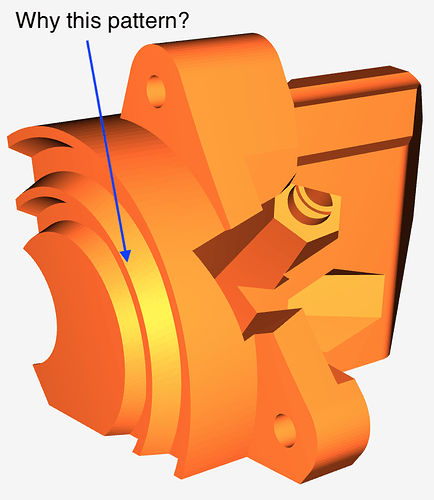

We couldn’t think of anything fun during beta so I just did something instead of leaving it plain. I like the other one better.