My job has slowed me down. Time to pick up the pace this weekend. I got it reassembled yesterday and started dialing it in today.my first cut was at 1/4" DOC to check for dimensional accuracy. Spot on. Then I ran another test at 3/8" DOC to check for chatter. NO CHATTER along the X axis. There was a little chatter in one direction along the Y axis. I think I need to tram it again. Finally I cut a couple of my new Y plates at 1/2" DOC. I borrowed my wife’s camera and tripod to record the 2nd cut and uploaded the video to my Google drive:

https://drive.google.com/file/d/1rbedu2z8H7LNzEnIwbczUa5UxgFmzoGa/view?usp=drivesdk

It’s over 18 minutes long and not very exciting. But it does show my redesigned X axis stepper mount in action.

I received a nice IM on the company’s messaging system late Friday. It was from the owner’s wife. She reminded us that we get Columbus Day (also Canada’s Thanksgiving) off. The owner is from Toronto.

Guess who gets another day to play with his Lowrider…

Looks really good, however I’m noticing some judder or racking in the tool head as I

watch the video.

It looks easy to counter though with another set of 4 - LR2_X_mount mounted to the

underside of a skeletonized top plate ~330mm x 200mm and then connected with

threaded rods through the bearing carriers to tension the whole assembly as a box frame.

I mentioned the judder in an earlier post. It is prominent in only one direction. I don’t think the spindle is trammed accurately on one axis.

I have a similar solution in mind after I finish assembling my kitchen island.

In regards to the potential tram/judder issue I’m interested in seeing how your solution works out. I’ve experienced the Y-axis pitching under load especially when near the midpoint on the X-axis. To counter this I increased the tube thickness to 0.083", however I haven’t eliminated it completely.

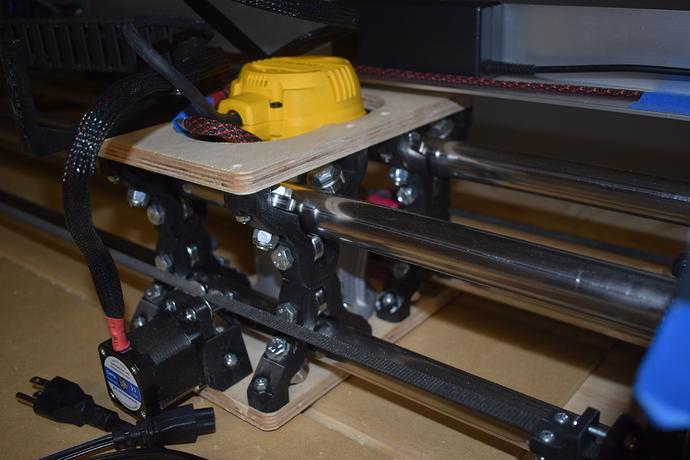

I finally had some time to work on upgrading my Lowrider yesterday and early this morning before work. I replaced both Y plates because I inadvertently changed the geometry incorrectly while widening the plates for the vertical X motor mount and butchered them with my jig saw just get the Lowrider functional enough to cut good plates. I added a 2nd pair of wheels to the bottom of each plate to ride in the matching groove on the bottom of the Y rails. I added a 2nd gantry plate to the top X-axis rails including a spindle mount to secure the top of the spindle.

I needed a few internal supports for the hollow columns I am installing from my new island to the ceiling. I cut 3 pieces using a 1/8" upcut end mill with DOC at 3.175mm, 6.35mm and 9.525mm. Then I changed to a 1/4" straight end mill and cut 2 pieces with DOC at 6.35mm and 9.525mm. Finally I cut 1 piece with the same final settings just to record it (about 3 minutes). All cuts were at 1000mm/min. I am uploading it to my shared Google Drive folder now. At the rate it is going it should be there in about 1.5 hours. It was recorded using my Note 9 so it’s not the best quality video. The link is:

https://drive.google.com/drive/folders/1-NlAQWnQT9-zR6cHg8TlpPaHQktba3oB?usp=sharing

Emboldened by what has been done…

For kicks I decided to make some mods, just to see what would happen. I’ve been seeing more 4-tube gantry lowriders lately (Like the Tom’s Nema 23 beast) and thought why not. Presently, I’ve run some tests and the 84 oz. in. Nema 17 steppers seem to work although I’ve yet to run any meaningfully dangerous speeds/feeds.

What’s been altered from stock:

- 2 Nema 17 84 oz. in. steppers on the X-axis instead of one.

- 4 tubes (like seen in this thread and elsewhere)

- Added a top X-Axis center assembly (no steppers, just X-Mounts)

- Joined the the X-Axis X-Mounts (I believe this will help with the pitching I observe during Y-Axis cuts)

- Increased the stepper motor digipot current to 230. Plastic hasn’t been a problem though I’m still monitoring temperatures. Ambient has been fluctuating quite a bit the last several days.

I am looking forward to seeing your machine in action.

On your Y_plate_NEMA23_vertical_X.DXF file, is the overall panel size (not part size) in the drawing 18" wide or ??? See attached crude drawing. It comes into estlcam at over 449" and while I know it is a bigger plate than stock, I don’t think it’s that big

Check the units selected during import. Might be thinking it’s inches but the dxf is in mm (as an example)

Good call. Comes in at 17.717"

I did this project in mm. The overall size is the minimum stock size I wanted to work with.

The Y-plate is ~16.75 inches wide

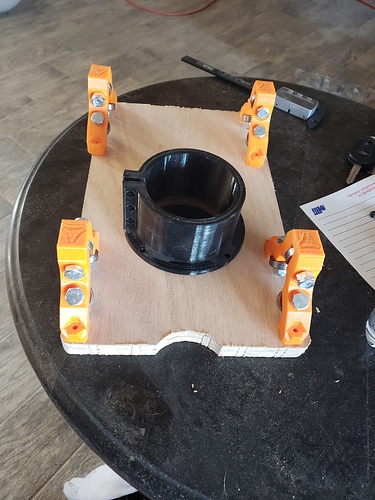

Some files on Thingiverse that might come in handy for this build. I’m presently using the parts for the x-axis belt as they are very rigid and quite securely hold onto the belt.

You metric guys, always throwing us old imperial farts for a loop

Thanks for the response. Won’t be cutting the plates for a while, but I’ll post updates.

Who? Me? I am an old fart, too. I am just trying to adapt in a young man’s world…

Trying to figure out the idlers & pulleys. Am I assuming correctly that the idlers on the X Motor Mount are 3M20T with a 5mm bore, and all the drives are 3M25T with a 6.3mm bore?

I’ve completed my 4-tube variant and must say it is much more rigid on the short axis (x on mine).

I’m calling it “The Sandwich”

I am new to creating my own CNC. Last two came complete. The best was a 4x8 warthog out of TN. Sold business and had to part ways.

I want to build my lowrider2 the right way the first time. All that I have read on this site and others tells me that this style of setup is best.

I just ordered a new 3D printer that will product 330 x 330 x 400. I want to print all the parts necessary. Can you direct me to a listing of printing files for this 4 SS pipe design.

I can find the pipe but need to get temple for the wooden “flat” parts”. Any help?

I plan on purchasing the hardware kit from Lowrider but have to figure out how to do it without ordering something twice.

I plan for the NEMA 23 steppers. What controller would I need to push the steppers? I noticed the Rambo but it only has 4 stepper connections.

I would also like a larger LCD as I have a bit of trouble with viewing screens. Eye troubles from working with software most of my life.

If you say “this guy doesn’t have a clue” I would respond with - “you are correct”! I hope the all of the know how can talent can direct me step by step.

And if you are ever in the Georgia near Rome a free steak I will buy you.

Cheers