It´s time to move on in my journey and have a look on how I am going to try and square my L2. I suspect that part of my experiences are caused to bad printed LR parts, but also due the fact that my wheels are slipping on the slippery surface I´ve got.

I´ve seen that some users add a beam to keep the wheels aligned, some make grooves for the wheels to run on. I was considering linear rails as a solution.

I was never planning on building a full sheet CNC machine. It just happened because I can do it  And that´s now causing an issue to find a linair rails long enough to fit.

And that´s now causing an issue to find a linair rails long enough to fit.

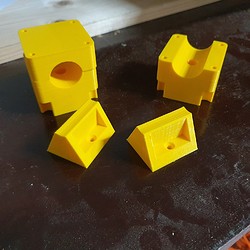

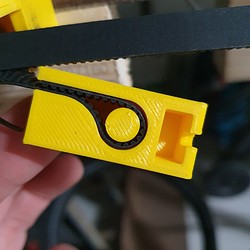

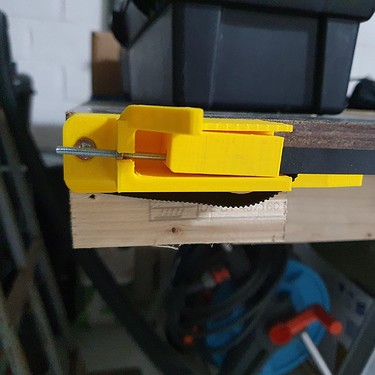

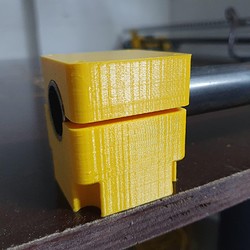

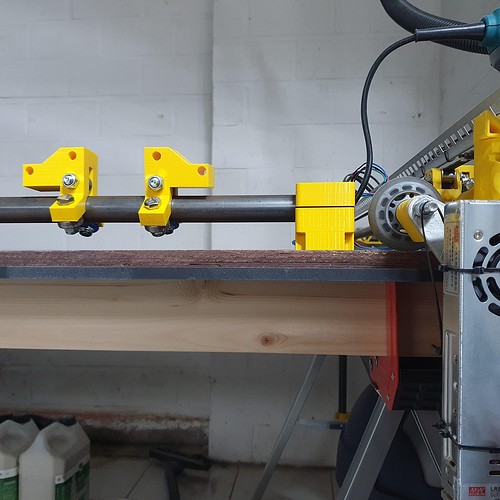

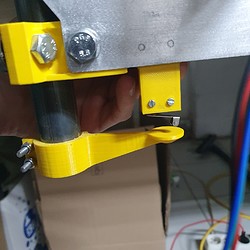

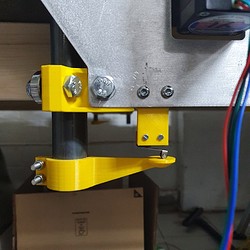

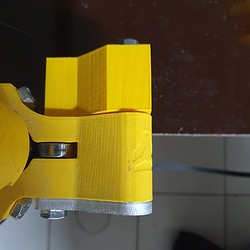

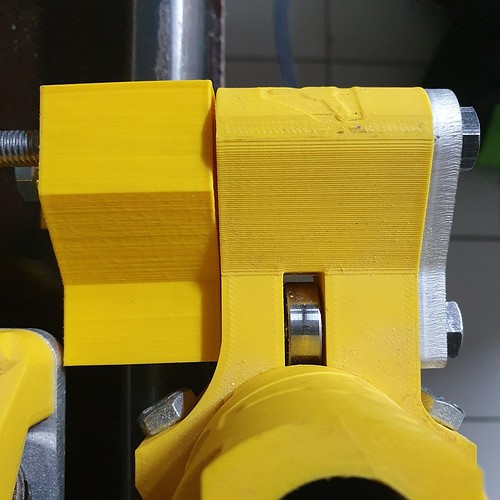

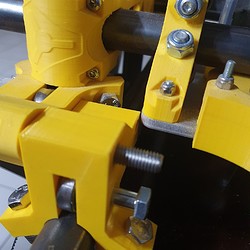

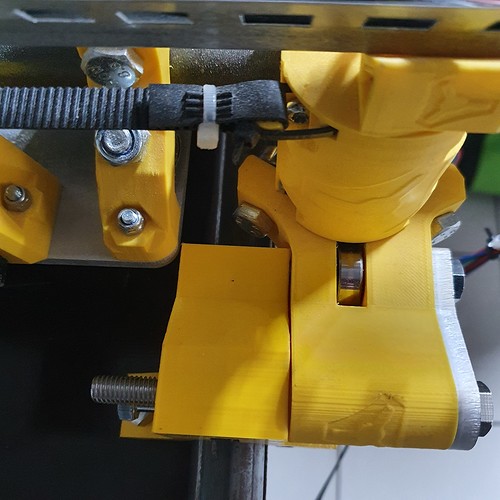

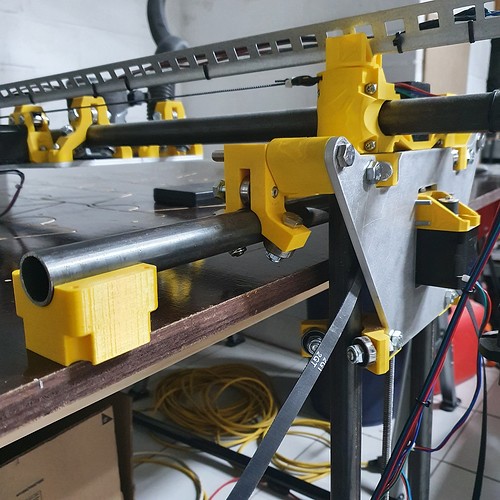

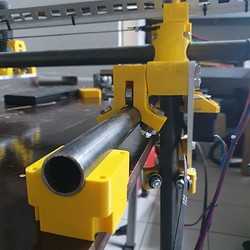

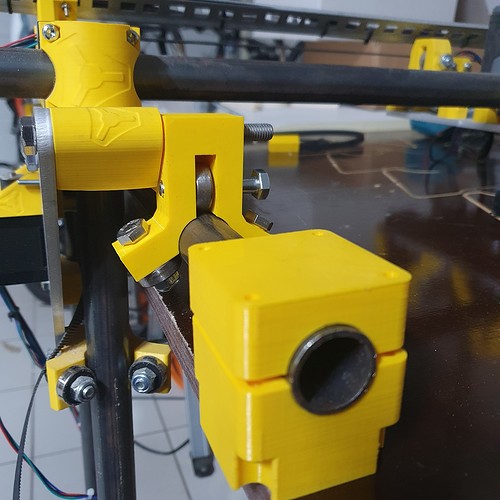

So, I found this earlier on Thingiverse:

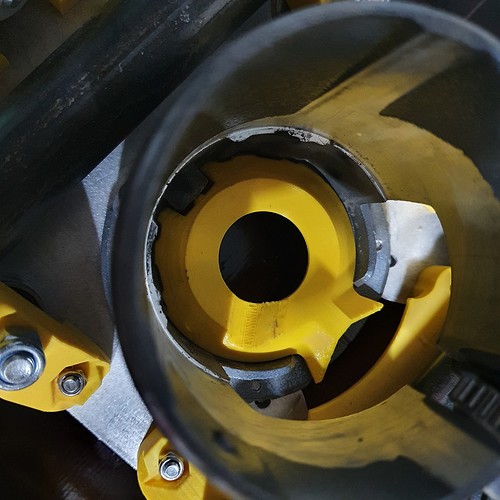

It is basically something bolted on the stock LR parts, and using the same principle for the Z/X axis. For the rails to mount they use this CNC alternative:

Now, I am considering to tackle this by a different approach.

I was hoping to mount M8 bolts /threaded rods to the tube, and mount those to the table. That way I can create some overhang to reach the outer sides of the full sheet without making my table larger.

I would add nuts between the rail/table to stabilize the whole on my required height.

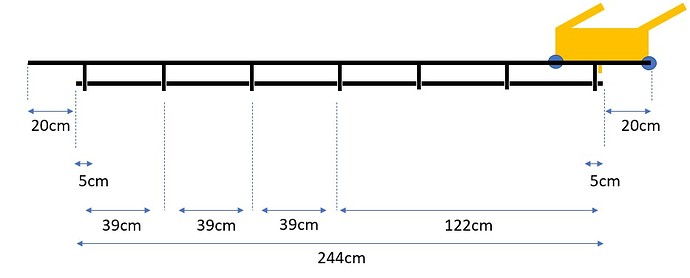

A sketch to make it more clear:

Like you can see, I would overhang the “rail” ± 20 cm on each side, that should be enough for the bit to go from 0 to 244cm (full plate lenght).

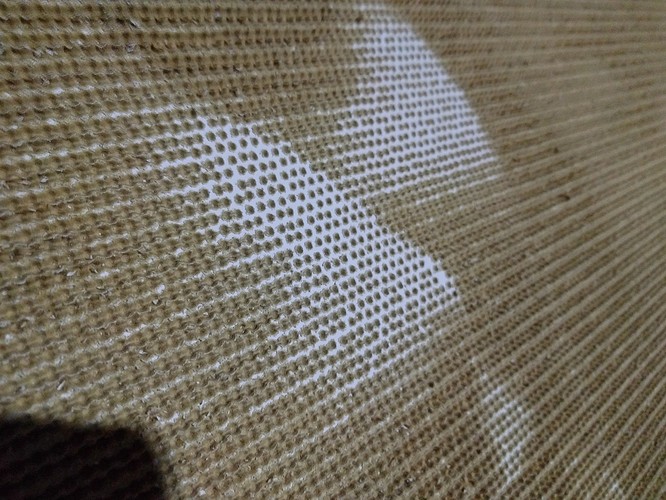

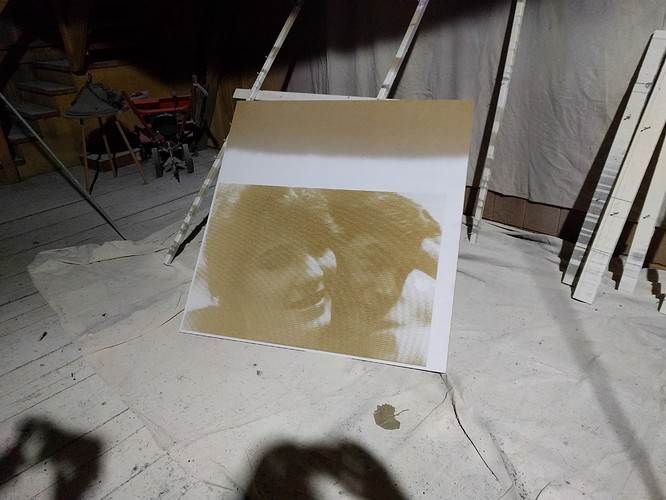

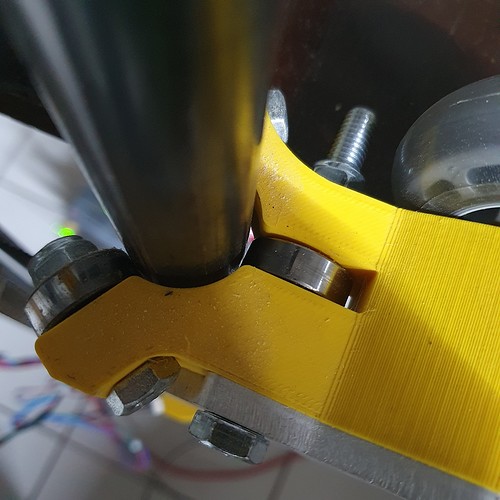

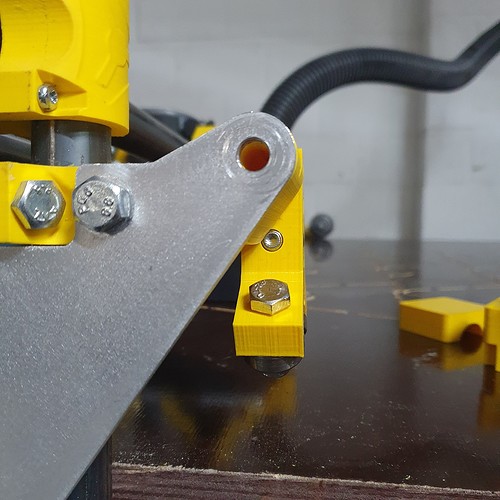

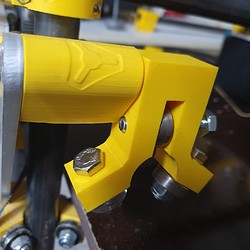

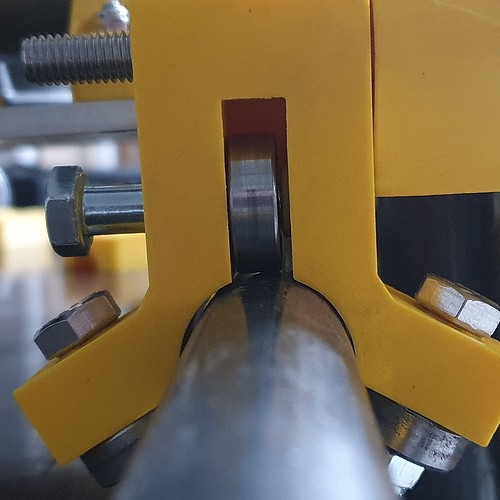

For mounting M8 bolts I contacted my local metal shop, they did an experiment for me, to check if they could mount blind rivet nuts to a 25mm round tube

This is their result:

As you can see they tried various options, and all with success.

So I believe my idea of mounting this using bolts is feasible. What do you guys think of it?

I am a bit worried on the distance I would choose between each of the holders (39cm) but since the X axis is longer and uses a similar principle, I believe that I might get away with it.

any suggestions?

![]()

![]()

![]()

![]()

![]()

And that´s now causing an issue to find a linair rails long enough to fit.

And that´s now causing an issue to find a linair rails long enough to fit.