So, I believe that I´ve passed the point of no return, and my Lowrider 2 journey is really starting.

After reading a lot on the subject, I thought to have a good idea what I´m into. However, after receiving nearly 60% of all parts, it seems that there will still be some questions to be answered.

What better to do this by making a build log?

Some background: I´ve got 0 experience with CNC, mostly this is outsourced for my little side hustle, by sending a sketch to a CNC company.

I hope to use the LR2 for some rapid prototyping. Materials I´ll want to cut are: Acrylic, Multiplex (Plywood?), Veneer and I am interested in EVA foam too.

Because of renovations, my workspace will be limited. In time I might upgrade to a full sheet size.

The workspace will be used for the LR2, and when not in use, it will function as a workbench.

It will be made out of 2 sheets 18mm Multiplex. Combined with 2 wooden beams to get a table height of ± 90cm.

The idea is to make some kind of a torsion box below the table deck to make it more rigid.

I choose to make it with Multiplex as I believe this will be to only material that will be level and straight. Here is a quick and dirty draft to get my idea.

I made a draft on paper, calculated all parts, and imported my results in an optimizer tool. To maximize the design based on Multiplex sheet sizes.

The exact dimension will be 213,8 x 103,6 cm. The (single sided) torsion box wall will be 14 (top) and 10 cm (bottom) height.

Although, I am considering it to lower it to 9 cm at the bottom, so I could add an additional horizontal beam in the middle to increase sturdiness.

So, got to think about the final design once more, and get the wood so I can start building soon.

I initially wanted to buy parts in the V1 store. But calculating import tax, it became clear to source it in the EU instead. (sorry Ryan, if I lived in the US I would have ordered instantly as they are fair prices)

For others in the EU, also sourcing parts, some leads:

- 608 bearings: Motedis, a German shop (warning slooooowwww handling of orders)

- GT2: Hobby Store Poland has 10mm, fiber belts.

The downside is that they only stock 20T instead of 16T. So will see if I need to change it. - Couplers, grease and leadscrew/nut also came from them. I probably went overkill taking 40cm instead of 30cm Leadscrews

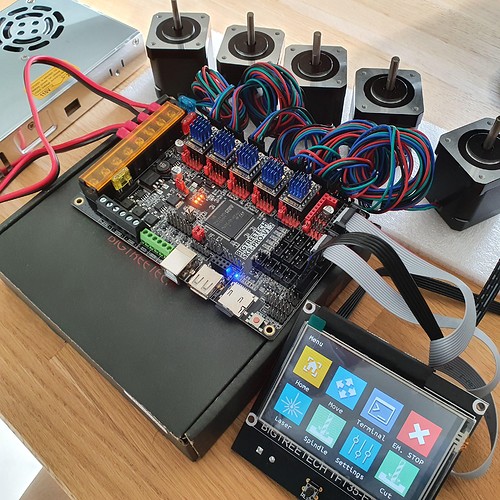

- Power supply: I got a Meanwell copy: 12V 30A from Poland as well. Should be enough Ooomphh!

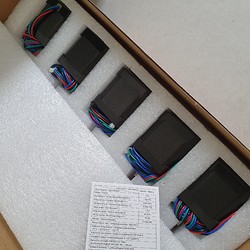

- Stepper motors: I ordered the V1 recommended ones on Amazon Germany

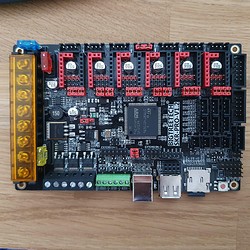

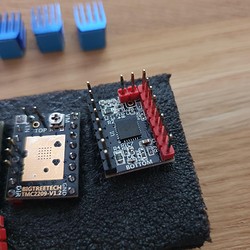

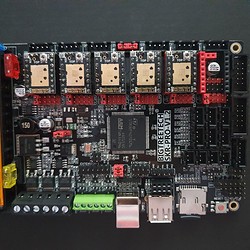

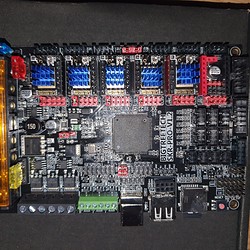

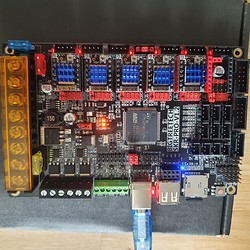

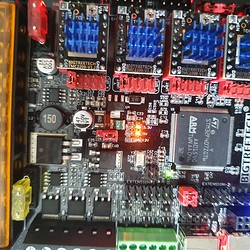

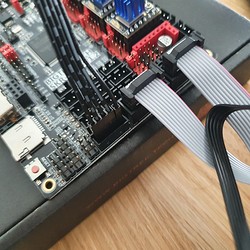

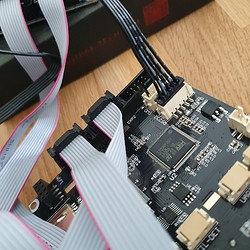

- SKR Pro 1.2, 5x 2209 drivers, TFT V3 E3: Amazon Germany, same price as V1 shop.

- 60mm wheel & spacers: Skate Dump Netherlands, 0,5€ per wheel. However I am still waiting for them to be delivered.

- Hardware: DHZ proshop Belgium – you can buy the exact amount you need.

Warning: take a good look at your cart, it was that cheap I accidently ordered 6 boxes of lock nuts. So I got 1200 of them instead of 6

- Flat parts: I ordered the Alu ones from Bozpet (check the “For Sales”-channel). I expect them any day now.

I will still need to buy the pipes, and a spindle. But this will be done when nearing completion of the table…

Now up to my questions, hope anyone could help me.

During the weekend I wanted to start on the SKR Pro configuration. But I doubt if I understand the FAQ correctly.

I want to use auto square functionality. AKA Dual End Stops. The FAQ mentions to remove the Sensorless pin.

Do I need to do this for Dual End Stops? Why not just keep it?

And, I believe it would be best to remove it instead of bending? To avoid shorts and static noise?

I also wonder about the default V1 software configuration. The FAQ speaks about EXTRUDERS=0 or EXTRUDERS=1.

As I understand it, it depends on where I add a stepper driver, and where I wire the stepper motor.

But what is the default configuration of the default V1 firmware? Is it =0 or =1?

The SKR did not come with a manual. How do I wire the power supply? The FAQ shows 4 wires, is that the way to go? My common sense thinks that 2 wires should be enough

Did anyone re-solder the stepper motor connectors? I do not like them to be removed as the FAQ suggests, I´d rather solder the correct connector to the stepper motor instead.

Can anyone confirm that it should be JST-XH connectors?

Final question; how many switches are needed for Dual End Stops?

My common sense says; 2x on each X, 2x on Y, and at least 1 on Z (touchplate not including). So that would be 7?

However the FAQ shows only 5 connectors to be plugged in?