Ok, finally getting around to a follow-up on my experience cutting those plates last night.

I made 2 mistakes…part of the learning process I guess.

First mistake:

I didn’t realize my router was sitting too high in the mount. So about 5 holes in I realized that the last 3-4mm of cut depth the core was riding on the workpiece and wobbling around.

So I had to stop, readjust router depth, and move down my board and try again.

Second mistake

After the first cut went ok, I went inside for a bit, then back out to the garage.

Started my job, it marked my 12 holes, and tool change time.

So I grab my tools, change the bit, power back on the router, and press Resume. Crap! Forgot about the probe. So I had to rush and turn off the router and grab the probe. In my rush, I accidentally knocked the probe and touch plate together as I fumbled to retrieve them.

So there I was…with my Z 20mm above the workpiece contemplating what to do…and I did the wrong thing.

What I should have done:

Stop the job. Return machine to X0 Y0, Run the job again. This would have let me verify that the first tool hit the exact same holes again as it should, and I would know it would be alright. I thought about this being the correct way to do it 4 seconds after it was too late…

What I actually did:

Thought to myself: Oh, well I think this tool change looks like it must have come back to 0,0, so I stopped the job and started over. Then my V bit was off and didn’t hit my original hole.

I found out that the tool change code actually moves to X0, Y10 shortly after I had already started the new job… so I had to stop and move down my board, and start over again.

I’ll likely change my tool change code to go to 0,0 instead of 0,10 just in case I need to stop and start over again in the future like that.

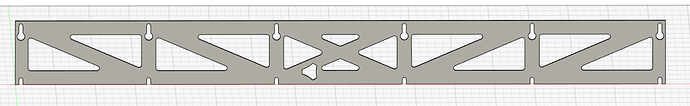

In the end though, I finished the night with 2 usable YZ plates, which is what I was after.

Follow-up

Tool change

After a very short time marking those small holes on the YZ plate, the bit and router is already extremely hot. What are you guys using to do your tool changes? Is it just my router getting hot that quick? I measured it in the 120-140ºF range.

Probing

After Probe, the imported settings move the bit to Z10. This is a really tight spot to unclip the probe. It’s probably fine if you are just using the magnet, but I think I’ll raise mine to Z20 for a little extra space

Makita Router

As I said, my router gets extremely hot. Like I’m concerned I’m risking deforming my PLA. I ran a surfacing job the other night and made the mistake of running it between 1 and 2 on the speed dial towards the end. Makita says don’t do that  . The cooling fan doesn’t move fast enough at low speeds, so afterwards I measured the temps north of 150ºF.

. The cooling fan doesn’t move fast enough at low speeds, so afterwards I measured the temps north of 150ºF.

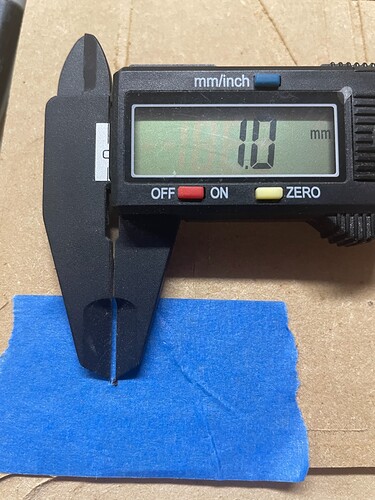

LR Core

I think my core has a little bit too much play in it. Some of my bottom bearings seem too loose and it feels like the core can move too easily, as I saw when it bottomed out. I’ve seen a few posts about tightening and squaring the router, but I still don’t quite have a handle on what I need to do, like a clear picture of exactly what happens when I tighten/loosen each those nuts.

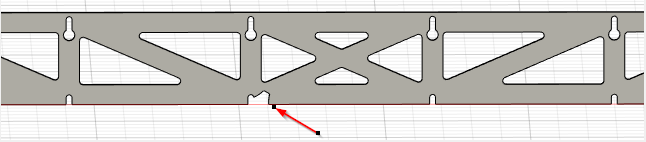

Some of the cuts showed a little bit of slop in them because of this, as you can probably see in the picture.

FluidNC

It would be nice if those messages telling you to probe and whatever had some kind of popup. Some times I sit for a bit before I realize it stopped for me to do something since I don’t have my router controllable by the gcode yet, so I don’t have the power off to prompt me.

I also saw in the Discord that there is a Probing tab, but it is missing from my interface. I also see someone mention Tablet Mode vs Regular mode…anyone know what that is??

Alright…rambling over for now…we’ll see what I “learn” tomorrow