Hello all,

I am looking to purchase the lr3 kit but i am unsure of everything i need to purchase. I am looking to buy it all from this site for a 4x8 full sheet table. any help would be appreciated.

The shop should give you a pretty solid overview.

Otherwise try this page: LowRider CNC V3 - V1 Engineering Documentation

Thanks for the reply, and yes i read through that before. I know zero about all this stuff so i want to make sure i have everything for the first go .

You could always put everything you think you need in the basket and post a screenshot here, then we can tell you what might be missing. ![]()

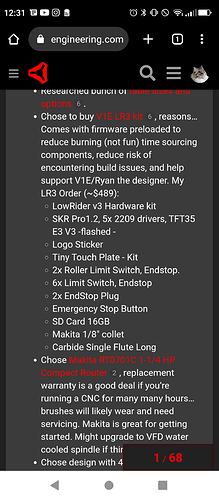

Hello @Roadrcr2000, think you need Endstops, consider getting cutting bit and collet too. Here’s my order, was for Makita based LR3 and I 3D printed parts.

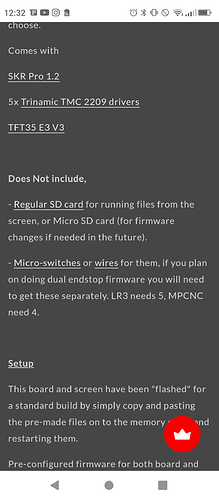

If you haven’t already, see V1E Shop’s page for SKR Pro, there’s some “does not include” verbage. I bought extra endstop switches they’re cheap and can break/get-lost.

Snapshot from my build journey:

Hope that helps, cheers!

Aren’t the endstops in the hardware kit?

I agree with the collet (if you have a Makita) and bits though. ![]()

Short: No.

Long: No. See “still needed” section of LR3 kit page. Some endstops come with Rambo, but not SKR. LR3 needs 5, but get an extra. I almost tripped on this too. I was bouncing around between pages looking at the details piecing together what’s needed. Wasn’t 100% sure I had the right items, anxiety and such… I get not everyone might want the Endstops, but guessing most do. Only Ryan knows if many people get tripped up on this one.

If there was a single “LR3 Complete Kit, everything but the EMT/table”. I probably would have bought that, especially if the page sold me on time and material, like how many hours it’ll typically take (assume Ender 3…) to tune, test print, then actually print parts and mill plates on average printer and baby CNC (include setup time, heat up, cool down time, etc …). For the LowRider 3 printed parts I specifically upgraded tensioner, dual gear extruder, 0.6mm nozzle on my relatively basic 3D printer. Goal was to print better dimensionally accurate, stronger, and aesthetically better looking parts. That all took more time and material than I originally estimated. Was great learning experience, but some folks with that knowledge/expectation upfront might be more likely to opt for 3D printed parts. Pure speculation on my part of course…

There’ll still be other stuff makers will need to have on hand, or get to complete their build e.g. heatshrink, wire sleeving, WAGO/similar connectors. Don’t know if these are explicitly stated anywhere. People customize and go their own way on a few things depending on what they need/want out their machine and their build experience.

Ok so 6 end stops , Im a dewalt person so is there any advantage to the makita in this application ? And thank you both for your help so far .

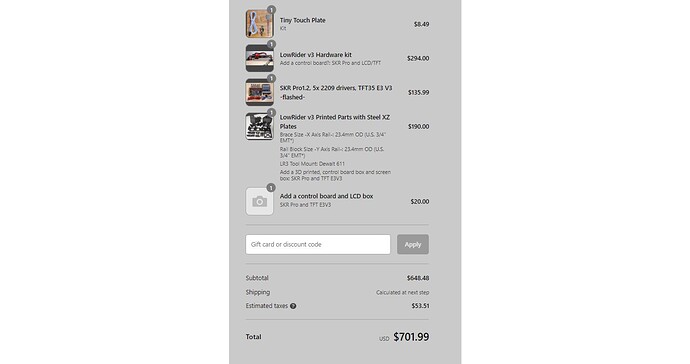

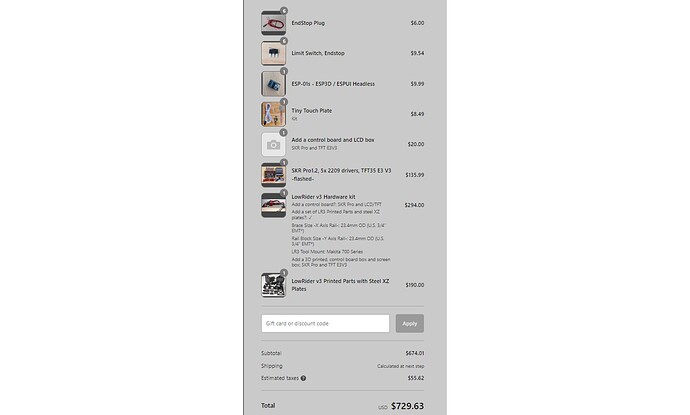

Ok this is my new cart ! I hope this is everything the reason I am not getting bits etc is because I am only planning to use ths with eva foam and maybe acrilic .

Not much between them afaik. Think Makita can be dialed down to lower RPM, that may be important to you depending on what you’re cutting. Dewalt has an integrated light, could be useful depending on your work area. Weight differences, but very similar power afaik.

https://www.amazon.com/DEWALT-DWP611-Torque-Variable-Compact/dp/B0048EFUV8?th=1

Noticed 6 endstop plugs in your cart, don’t know if that many are needed? Used a bunch of 22AWG stranded copper I had lying around to wire up some stuff after using up wiring from the kit. Consider checking the docs if in doubt, my knowledge might be stale, the docs have improved since I built and wired up my LR3. Good luck!

Didn’t see YZ plates in the list.