Wondering if anyone has ever seen like a 1” or 2” long (cutter) 1/8 endmill in their travels? I’ve got a 2 1/2” that tapers from 1/4” to 1/8” but would rather one without taper.

Quick search on amazon shows this one…

Not sure if something like that is what you are looking for or not. Doesn’t seem real long but it does have a longer than normal cutting area for 1/8"

As I was trying to get my sore body back to sleep this morning (big carving day here yesterday) it occurred to me that I have some drywall cutout bits that are long enough but I need to check them to see if they are up cut or down cut. If they’re down cut that wouldn’t work - but I guess I could always flip the plug in in the wall. ![]()

Not sure if something like this could work with ice.

Someone else was cutting foam with some really long cutters but I can’t find the thread.

zip bits are usually downcut, so they throw the sheetrock dust away from the cutter.

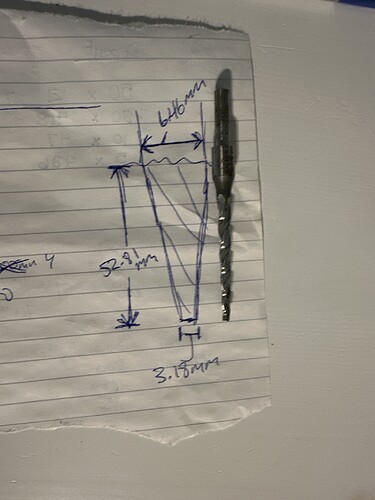

My carving partner and I were talking about this and having a look at this bit I have. It’s tapered but maybe would still do the trick - it’s a very slight taper.

SpeTool Extra Long CNC Spiral… Amazon.ca

I have a couple if these, and a couple of the same but downcuts.

It’s about 1" cutting depth, and 3" overall length. I use them for deep cutting operations. They’re 1/4" shank but 1/8" cutting, no taper.

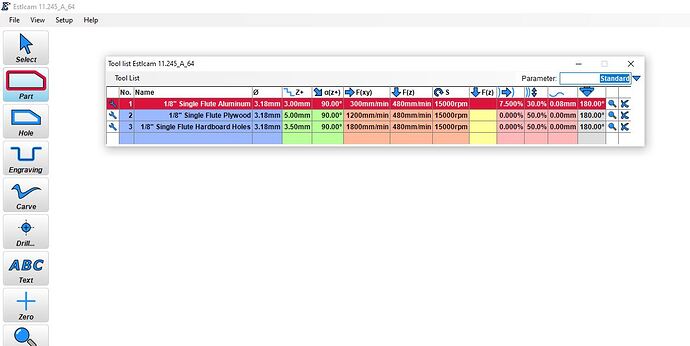

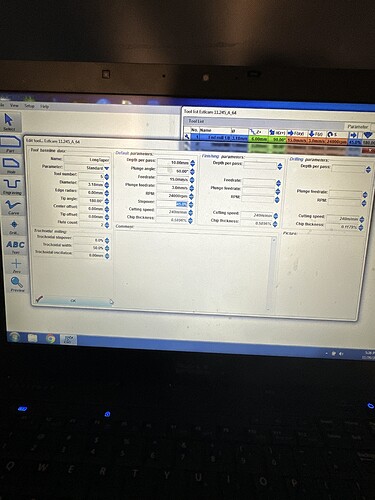

I can’t recall off hand how to access the spot in Estlcam where you can add or remove tool parameters. Trying to configure that long bit. I’m using Estlcam 11 at the moment. I don’t see a cell for inputting the cutter length.

Click on the empty blue line just below the last tool, and it will add a new tool. Click on the wrench icon to modify that tool’s settings.

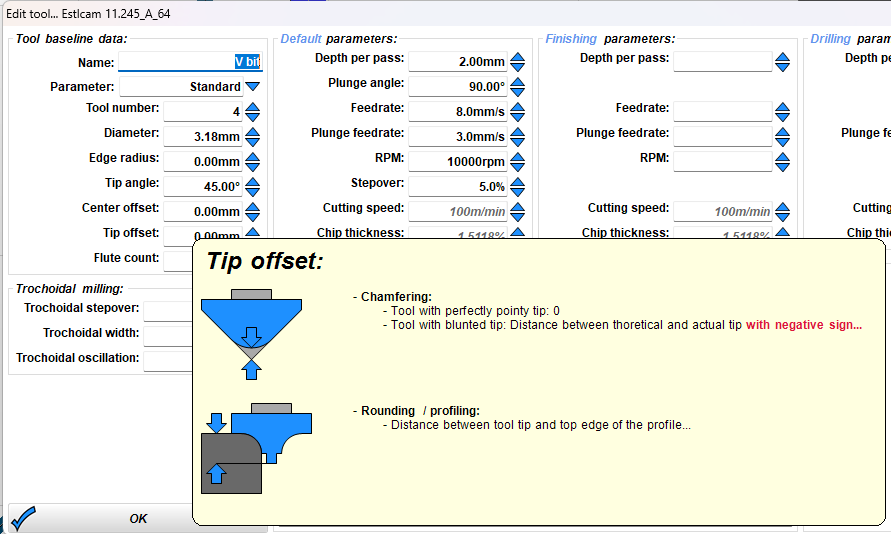

Perfect. Thanks. I don’t see anywhere that I can address the flat nose and the taper and the length here. What am I missing?

That is the 180 degree tip angle

Not really programmable, other than possibly DOC per pass

Not sure about that, I think that EstlCAM assumes a straight bit (except for V bits). Perhaps someone else might provide a better answer

Maybe I can cheat the system and specify it as a very shallow angle v bit but know in my mind that the tip is blunt? I feel like the v bit distinction is specific or at least most critical to the carve function. If I recall correctly there’s a tool change built in to the carve function for the pocket clear out.

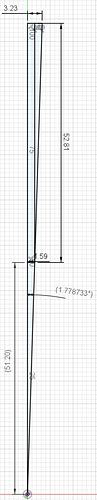

Is that 6.46mm measurement at the top part of the taper? If so, I think you want these values but someone should sanity check that. I just put it in CAD and let it calculate it. I split it in half and doubled the angle.

Diameter: 6.46mm

Tip angle: 3.56 degrees

Tip offset: -51.2mm

Oh man you guys are awesome! My “faking it” might have caused a whole pile of AirPrints. I saw the tip offset but never thought to rollover it for more info. Thanks so much. I’ll set it up and try it tomorrow. If it works I’ll have to pull the secondary core off to test the job I’d be using this specific bit for but I think that’s actually pretty easily done.

V12 has got some more settings for those specialty endmills as well. ![]()

Do you think it’s worth the switch? What’s the learning curve like? I feel like I’m pretty comfortable/confident in 11/10.

If 11 works for you, don’t switch. ![]() 12 has got a lot of cool, new features and better carve calculation, but besides that 11 is absolutely fine.

12 has got a lot of cool, new features and better carve calculation, but besides that 11 is absolutely fine.

V12 had a very short and shallow learning curve for me, and I wasn’t even that familiar with v11. If your license is valid for both, then no reason not to transition (imo), other than the fact that v11 projects and files aren’t compatible with v12 (and vice versa).

I appreciate you doing that, thanks. I’ve got it set up and a test file CAM’d. I’ll try it tomorrow and hope it doesn’t tear apart the Lowrider. ![]()

This has also motivated me to get the build going for LR32…started sanding the printed parts this evening. Pretty boring task but it’ll be worth it in the end.