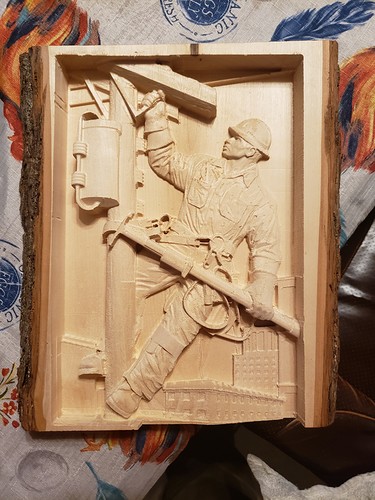

I hope I’m putting this on the right place lol I did this on my low rider yesterday with an 1/8th inch bit and a 2mm ball

I moved it to the Things you’ve made section for you.

Awesome work

Thank you

That’s awesome. Very detailed. And very deep. Nice work.

Thank you

That is so cool! How large is it? Can you explain your workflow?

Beautiful, beautiful work!

Please tell us about the wood it is carved into. Is it some kind of glue up or one piece?

Beautiful !

Sorry it took so long to get back to you . It is one piece of solid bass wood I am almost certain that is what that piece of wood was. It took a long time to machine mostly from me being way too conservative on my passes and depth per pass i could have taken at least 1/2 again as much and and 700 mm a min faster x travel speed.

Thank you. I would have to measure it but I think it was 12in x8 in if I remember right . I am not sure what you mean by workflow, sorry. I think I ran it at 1000 mm a min travel speed with an 1/8th inch bit on the first pass Then for the finish pass I used a 1mm ball at the same speed now that I have cut other stuff out of that wood and learned more I know I could have taken off almost twice as much per pass and 500 mm min faster

Thank You??

Where did you get the wood blank?

This is awesome, thank you for sharing! I have a log of London Plane from my neighbor’s tree that I was planning to saw up for similar projects. Seeing your carving is a big inspiration to me. I can only hope to come up with a model even 1/100th as nice as you have there. I love the depth and detail… exactly the kind of thing was envisioning for my log.

I got the wood blank from michaels craft store . They actually have a lot of nice wood stuff there like boxes you can customize I have a laser that I can cut boxes out with but for the price they want I just buy the box then engrave it.

Thank you for the compliment make’s me feel proud of what I did . I am still learning and have only done a handful of cut’s that have come out like I want that is the best one I have done. I have only been doing this for a few months . I am still learning what kind of speed’s I can do and how much can be cut. I wish someone on here had a cheat sheet for speed’s and cutting amounts you can do with various types of material . I tried some aluminum the other day it was coming out really good but my router died I got another one yesterday so will try the aluminum again. This is a kind of off topic but has anyone else had trouble with the Dewalt routers I have gone through two in a few months I run it on low I don’t know if I should run it faster also I have not been removing much material so it has been almost running free just curious if anyone has any thoughts , or simulure problems. Sorry for such a long reply typing between customers at work so kept adding as thought of stuff lol .

Unlike many, I have never liked the Dewalt router. I have used both the Bosch Colt as well as the Makita trim routers, which I find less noisy, with downdraft cooling (to help clear chips) and reasonable speed deviation under load. I’ve not had any failures after 2 years of use on the Colt. Makita seems to be very similar but I’ve only got 4 months on it.

I will have to try the colt when my warranty is up or ace quits giving them to me the dewalt I got this time actually seem’s quite a bit quieter and smoother maybe I got 2 defective ones some how. Is there a brand of bits or certain ones that cut better than other’s i have some that work good but am to the point that I would like to get some really good bits that will last and maybe cut faster or more thank you

For the most part, the dewalt was the router to use because it has plenty of horsepower, and was cheap.

I’ve used mostly Whiteside end mills and have been very pleased with them. Even cutting some stainless steel did not do one of them in, surprisingly. But, there are lots of good quality ones if you avoid the mostly junk on Amazon.