Since we were hijacking a different thread, and I always like these…

I have an entire thread dedicated to mine ![]()

Nice. I wish I had that kind of space. And the spouse wishes she could park in the garage…

…I guess it’s fair neither of us get what we want, haha

Wow - that’s an impressive shop!

Very nice. Chad wins. Thread over. Lol

Haha, I hope not!

Semi-related, the lathe standing on end behind the RAS, and the 1940s lathe, is one my grandfather pieced together for me for Christmas when I was about 12. Nothing on it is standard (can’t get a chuck that fits it), it’s hacked together…and I’ll likely never use it again… but I’ll also probably never part with it ![]()

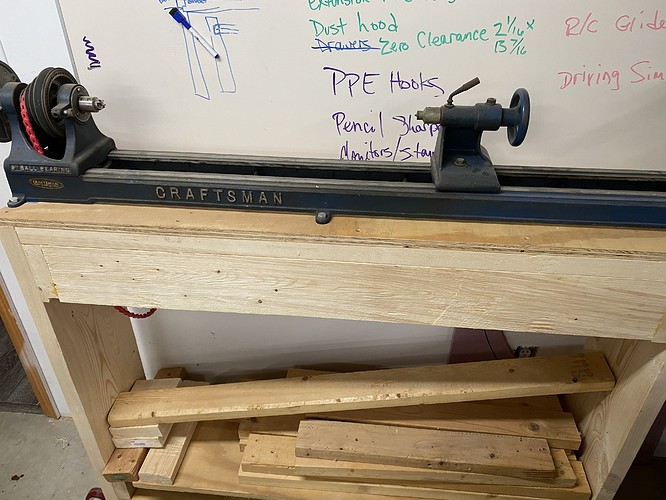

Too embarrased to share whole shop pictures at the moment but an early Covid sequestration project was to finally get the 1934 lathe onto a stand so my daughter could try pen turning at home. She’d gotten to try it at school last year. Turns out the old lathe has a solid, not a morse taper, headstock, so it won’t accept the turning mandrel her shop teacher let her bring home. I wish my grandfather had sprung for the 12" instead of the 9" version.

Got a basic frame together but stalled out at getting the motor mounted. I even have a a treadmill motor, PWM board, tach, and reversing switches all lined up. Need to get this from 95% to complete.

I’ve got way too many projects just “this close” to being done.

dayum, that powermatic is a big beast

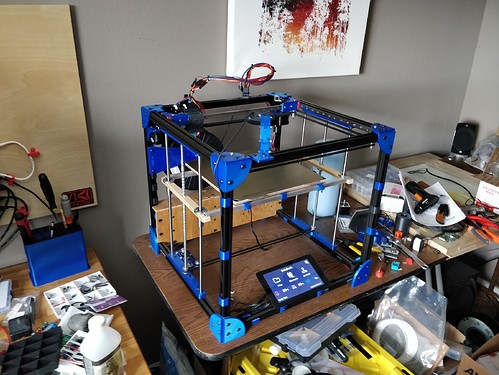

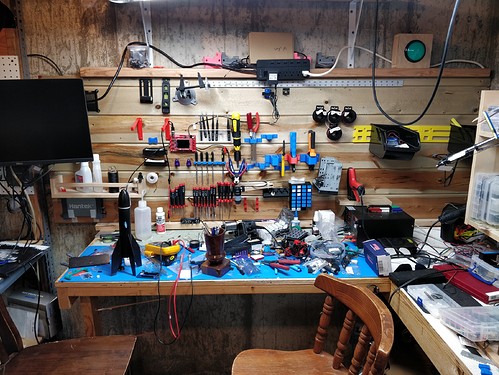

Ok. Here are my messy maker spots.

First, the shed. Which is 16’x10" and in the back yard:

It currently is just the table saw and the drill press. I have some more power tools I need to migrate into it.

My 4’x3’ low rider is in the garage, along with the tool wall for all the house construction tools.

I like to think I am a Jack of all trades and master of none, but my main battlestation is for software engineering.

And I have a table there for current projects.

My electronics bench gets a lot of use, but it is 5 mins at a time, so I never bother to clean it off.

Posting these pictures makes me really want to clean up. I like to hang stuff on the wall (can you tell?) But that means that I usually just drop stuff on a horizontal surface until I build a mount for the vertical surface. I probably need to design and print about 100 more mounts for stuff. The first 20 were fun but …

Was that belt still in stock at Sears?

That particular link belt gave me headaches. I used a Harbor Freight linked belt on the Craigslist mid-50’s tablesaw and it made a huge difference, so I got one for the lathe, but it rode too high in the pulley and rubbed on the frame of the machine. For some reason, the 1/8" narrower link belt was only available online in a way longer size (not really a problem) and at about 3x the cost.

Yeah it is. With the 4" risers it can swing 20" over the ways and 26" over the gap. The pulleys on it are sized for bowls not spindle work. For littler things I use my Jet mini.

Not so messy Jeff. I wish I could have a shed in the backyard but we have neighborhood rules against them.

Glad to hear some schools still have shop class. I have a feeling my Powermatic lathe came from a dissolved shop class program. BTW, I know exactly what you mean about 95% complete, I’m kind of known for it. I got it from my Dad I think, he always had some project in clamps for months or years at a time.

Woohoo i love a good shop show and tell. I’m still afflicted with cars in my garage workshop but right now in deep northern winter I don’t mind a warm car to hop into.

We just crested 5 years in our house this past summer, first house for us, and first garage for me and it’s been tons of fun for all my love of hobbies and bits. We get proper cold here, so this past fall I finally finished up what I’d long planned to raise the ceiling, and heat the sucker. I love this picture of my boy, I imagine it as dad, wtf did you do! I’m a hopeless golf addict and I’m hoping to simulator golf in here so this was a bold/big move that had to happen before the heating/insulating step.

As my picture suggests I’m also into cars despite being a devout bicycle commuter? (lol?) so doing dumb car things is part of the fun, this was a strip job I did on a complete running '97 jetta in order to get an engine harness… yes, just the engine harness

here we are now post insulation heat etc, and with the actual project car and daily back in the garage

This was the last big project for the shop now for some time, I made myself a new workbench that incorporated my fav crafstman tool boxes with a custom bent steel surface to help me keep grease/auto dirt at bay and separate from my wood working cnc stuff.

this last big project included relocating my (probably too big) drill press which is super handy for metal work, but between these two guys I get a lot done

here’s my obligatory resting cnc with revised dust vac/separator setup (which has been excellent)

and here I am (hello everyone!  ) with my 3 yr old helper, on the phone with dad, taking a break from a wiring dilemma

) with my 3 yr old helper, on the phone with dad, taking a break from a wiring dilemma

I made a garage an absolute requirement in our house hunt and am so glad I did, and very thankful for an understanding partner.

Define, proper cold… It’s -20c here right now. ![]()

Awesome shop. My dad’s a mechanic, working on cars is fun.

I won’t go head to head with Winnipeg but I’m in Edmonton so we do our fair time at miserable temps. It’s a balmy -12 right now, but it can be t-shirt weather in the garage and that’s all that matters to me in lockdown