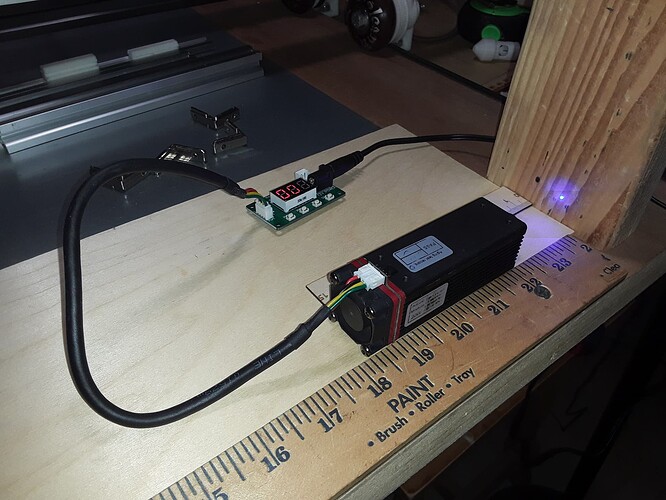

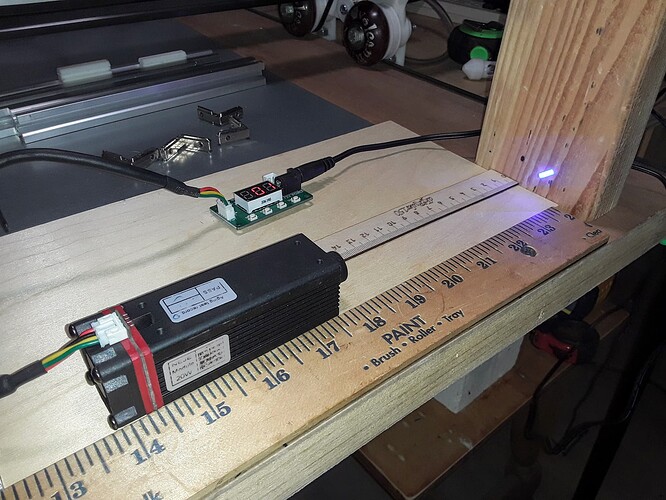

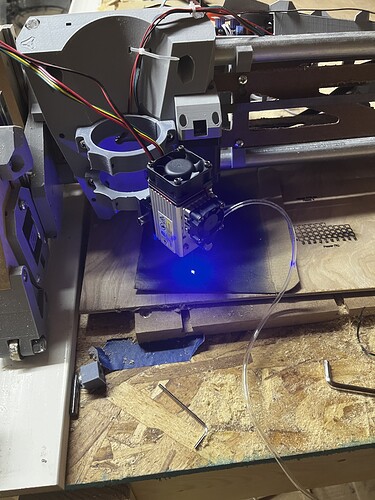

Okay so I installed the laser. I went to do the focus test through light burn when I use the lcd on the lr3 to initiate the test the screen says echo M8 unknown command. And the entire machine moves back from the staring point until I stop the machine. It doesn’t fire the laser or anything

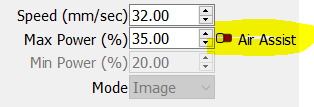

Edit: I figured out the M8 it’s to turn on air assist. Which I now need to figure out how to turn that off. I still am puzzled by the movement that is taking place to start the test. Attached is my gcode from test. While my LR is a full sheet, I have set the test parameters to the size of the ply I am testing on which is 21X30

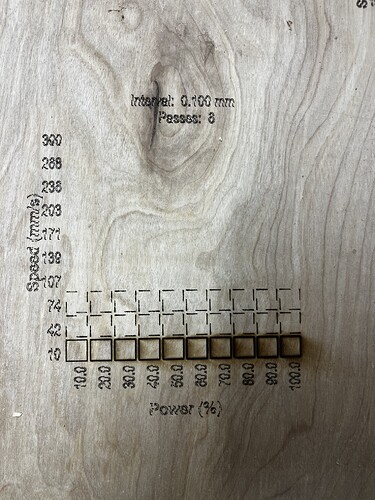

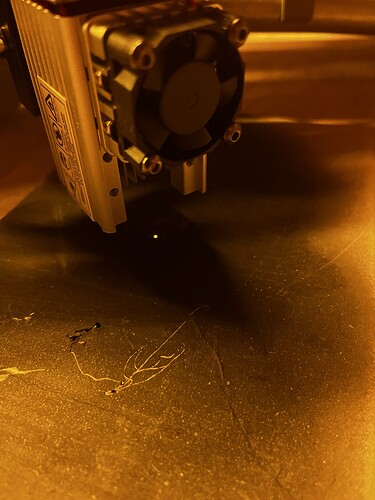

This last time I attempted the test, the laser did fire and continued to stay on a made a very light burn as it travelled.

I also have it set up in lightburn to be the starting point as the front left which I assume it means that if I stand in front of the table, the LR core, when homed should be in front of and to the left of me.

Edit: I just had a thought. I don’t intend to use the entire 21x30, just a small square say 8x8 or whatever. It’s moving that far because it thinks I want it to use the entire sheet isn’t it?

Please see gcode below:

; LightBurn 1.4.04

; Marlin device profile, absolute coords

; Bounds: X236.23 Y367.32 to X298.01 Y391

;USER START SCRIPT

M3

;USER START SCRIPT

G21

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X236.7 Y371 F0

; Layer

M106 S51

G1 Y391F3000

M106 S0

G0 X237.182 Y370.5 F0

M106 S51

G1 X236.576F3000

G1 X236.424 Y370.459

G1 X236.328 Y370.39

G1 X236.259 Y370.293

G1 X236.231 Y370.156

G1 Y370.059

G1 X236.259 Y369.921

G1 X236.341 Y369.811

G1 X236.452 Y369.728

G1 X236.576 Y369.715

G1 X237.664

G1 X237.802 Y369.742

G1 X237.912 Y369.811

G1 X237.995 Y369.949

G1 X238.009 Y370.059

G1 Y370.156

G1 X237.981 Y370.293

G1 X237.926 Y370.39

G1 X237.816 Y370.472

G1 X237.664 Y370.5

G1 X237.182

M106 S0

G0 X236.314 Y369.384 F0

M106 S51

G1 X236.245F3000

G1 Y369.205

G1 X236.424

G1 Y369.384

G1 X236.314

M106 S0

G0 X237.182 Y368.874 F0

M106 S51

G1 X236.576F3000

G1 X236.424 Y368.833

G1 X236.328 Y368.764

G1 X236.259 Y368.667

G1 X236.231 Y368.53

G1 Y368.433

G1 X236.259 Y368.295

G1 X236.341 Y368.185

G1 X236.452 Y368.102

G1 X236.576 Y368.089

G1 X237.664

G1 X237.802 Y368.116

G1 X237.912 Y368.185

G1 X237.995 Y368.323

G1 X238.009 Y368.433

G1 Y368.53

G1 X237.981 Y368.667

G1 X237.926 Y368.764

G1 X237.816 Y368.846

G1 X237.664 Y368.874

G1 X237.182

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X239.7 Y371 F0

G91

G0 Z0.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-0.5

G90

M106 S0

G0 X239.314 Y370.5 F0

G91

G0 Z0.5

G90

M106 S51

G1 X239.245F3000

G1 Y370.321

G1 X239.424

G1 Y370.5

G1 X239.314

G91

M106 S0

G0 Z-0.5

G90

M106 S0

G0 X240.995 Y369.301 F0

G91

G0 Z0.5

G90

M106 S51

G1 Y369.949F3000

G1 X239.975 Y369.976

G1 Y369.935

G1 X240.141 Y369.88

G1 X240.237 Y369.811

G1 X240.32 Y369.715

G1 X240.347 Y369.618

G1 X240.334 Y369.494

G1 X240.306 Y369.398

G1 X240.223 Y369.301

G1 X240.113 Y369.232

G1 X240.003 Y369.205

G1 X239.576

G1 X239.438 Y369.246

G1 X239.341 Y369.301

G1 X239.273 Y369.384

G1 X239.231 Y369.522

G1 Y369.646

G1 X239.245 Y369.742

G1 X239.341 Y369.894

G1 X239.438 Y369.963

G1 X239.576 Y369.99

G1 X239.755

G91

M106 S0

G0 Z-0.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X242.7 Y371 F0

G91

G0 Z1

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-1

G90

M106 S0

G0 X243.65 Y370.5 F0

G91

G0 Z1

G90

M106 S51

G1 X243.775 Y370.321F3000

G1 X243.995 Y370.142

G1 X242.245

G91

M106 S0

G0 Z-1

G90

M106 S0

G0 X242.314 Y369.728 F0

G91

G0 Z1

G90

M106 S51

G1 X242.245F3000

G1 Y369.549

G1 X242.424

G1 Y369.728

G1 X242.314

G91

M106 S0

G0 Z-1

G90

M106 S0

G0 X243.182 Y369.219 F0

G91

G0 Z1

G90

M106 S51

G1 X242.576F3000

G1 X242.424 Y369.177

G1 X242.328 Y369.108

G1 X242.259 Y369.012

G1 X242.231 Y368.874

G1 Y368.778

G1 X242.259 Y368.64

G1 X242.341 Y368.53

G1 X242.452 Y368.447

G1 X242.576 Y368.433

G1 X243.664

G1 X243.802 Y368.461

G1 X243.912 Y368.53

G1 X243.995 Y368.667

G1 X244.009 Y368.778

G1 Y368.874

G1 X243.981 Y369.012

G1 X243.926 Y369.108

G1 X243.816 Y369.191

G1 X243.664 Y369.219

G1 X243.182

G91

M106 S0

G0 Z-1

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X245.7 Y371 F0

G91

G0 Z1.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-1.5

G90

M106 S0

G0 X245.314 Y370.5 F0

G91

G0 Z1.5

G90

M106 S51

G1 X245.245F3000

G1 Y370.321

G1 X245.424

G1 Y370.5

G1 X245.314

G91

M106 S0

G0 Z-1.5

G90

M106 S0

G0 X246.995 Y369.301 F0

G91

G0 Z1.5

G90

M106 S51

G1 Y369.949F3000

G1 X245.975 Y369.976

G1 Y369.935

G1 X246.141 Y369.88

G1 X246.237 Y369.811

G1 X246.32 Y369.715

G1 X246.347 Y369.618

G1 X246.334 Y369.494

G1 X246.306 Y369.398

G1 X246.223 Y369.301

G1 X246.113 Y369.232

G1 X246.003 Y369.205

G1 X245.576

G1 X245.438 Y369.246

G1 X245.341 Y369.301

G1 X245.273 Y369.384

G1 X245.231 Y369.522

G1 Y369.646

G1 X245.245 Y369.742

G1 X245.341 Y369.894

G1 X245.438 Y369.963

G1 X245.576 Y369.99

G1 X245.755

G91

M106 S0

G0 Z-1.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X248.7 Y371 F0

G91

G0 Z2

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-2

G90

M106 S0

G0 X249.485 Y370.472 F0

G91

G0 Z2

G90

M106 S51

G1 X249.664F3000

G1 X249.761 Y370.459

G1 X249.871 Y370.404

G1 X249.967 Y370.307

G1 X250.009 Y370.156

G1 Y370.059

G1 X249.981 Y369.907

G1 X249.926 Y369.825

G1 X249.843 Y369.756

G1 X249.747 Y369.728

G1 X249.664 Y369.715

G1 X249.513

G1 X249.306 Y369.756

G1 X249.099 Y369.852

G1 X248.865 Y370.004

G1 X248.658 Y370.183

G1 X248.465 Y370.362

G1 X248.328 Y370.5

G1 X248.245

G1 Y369.687

G91

M106 S0

G0 Z-2

G90

M106 S0

G0 X248.314 Y369.37 F0

G91

G0 Z2

G90

M106 S51

G1 X248.245F3000

G1 Y369.191

G1 X248.424

G1 Y369.37

G1 X248.314

G91

M106 S0

G0 Z-2

G90

M106 S0

G0 X249.182 Y368.86 F0

G91

G0 Z2

G90

M106 S51

G1 X248.576F3000

G1 X248.424 Y368.819

G1 X248.328 Y368.75

G1 X248.259 Y368.654

G1 X248.231 Y368.516

G1 Y368.419

G1 X248.259 Y368.281

G1 X248.341 Y368.171

G1 X248.452 Y368.089

G1 X248.576 Y368.075

G1 X249.664

G1 X249.802 Y368.102

G1 X249.912 Y368.171

G1 X249.995 Y368.309

G1 X250.009 Y368.419

G1 Y368.516

G1 X249.981 Y368.654

G1 X249.926 Y368.75

G1 X249.816 Y368.833

G1 X249.664 Y368.86

G1 X249.182

G91

M106 S0

G0 Z-2

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X251.7 Y371 F0

G91

G0 Z2.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-2.5

G90

M106 S0

G0 X251.314 Y370.5 F0

G91

G0 Z2.5

G90

M106 S51

G1 X251.245F3000

G1 Y370.321

G1 X251.424

G1 Y370.5

G1 X251.314

G91

M106 S0

G0 Z-2.5

G90

M106 S0

G0 X252.995 Y369.301 F0

G91

G0 Z2.5

G90

M106 S51

G1 Y369.949F3000

G1 X251.975 Y369.976

G1 Y369.935

G1 X252.141 Y369.88

G1 X252.237 Y369.811

G1 X252.32 Y369.715

G1 X252.347 Y369.618

G1 X252.334 Y369.494

G1 X252.306 Y369.398

G1 X252.223 Y369.301

G1 X252.113 Y369.232

G1 X252.003 Y369.205

G1 X251.576

G1 X251.438 Y369.246

G1 X251.341 Y369.301

G1 X251.273 Y369.384

G1 X251.231 Y369.522

G1 Y369.646

G1 X251.245 Y369.742

G1 X251.341 Y369.894

G1 X251.438 Y369.963

G1 X251.576 Y369.99

G1 X251.755

G91

M106 S0

G0 Z-2.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X254.7 Y371 F0

G91

G0 Z3

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-3

G90

M106 S0

G0 X254.741 Y370.5 F0

G91

G0 Z3

G90

M106 S51

G1 X254.576F3000

G1 X254.438 Y370.472

G1 X254.341 Y370.404

G1 X254.273 Y370.321

G1 X254.231 Y370.183

G1 X254.217 Y370.114

G1 X254.231 Y369.99

G1 X254.273 Y369.894

G1 X254.341 Y369.811

G1 X254.438 Y369.742

G1 X254.576 Y369.715

G1 X254.893

G1 X255.017 Y369.742

G1 X255.113 Y369.811

G1 X255.168 Y369.935

G1 X255.251 Y369.825

G1 X255.32 Y369.756

G1 X255.416 Y369.742

G1 X255.678

G1 X255.788 Y369.756

G1 X255.885 Y369.811

G1 X255.967 Y369.894

G1 X255.995 Y369.99

G1 X256.009 Y370.073

G1 Y370.142

G1 X255.995 Y370.252

G1 X255.94 Y370.348

G1 X255.871 Y370.417

G1 X255.775 Y370.459

G1 X255.678 Y370.486

G1 X255.513

G91

M106 S0

G0 Z-3

G90

M106 S0

G0 X255.168 Y369.935 F0

G91

G0 Z3

G90

M106 S51

G1 Y370.266F3000

G91

M106 S0

G0 Z-3

G90

M106 S0

G0 X254.314 Y369.398 F0

G91

G0 Z3

G90

M106 S51

G1 X254.245F3000

G1 Y369.219

G1 X254.424

G1 Y369.398

G1 X254.314

G91

M106 S0

G0 Z-3

G90

M106 S0

G0 X255.182 Y368.888 F0

G91

G0 Z3

G90

M106 S51

G1 X254.576F3000

G1 X254.424 Y368.846

G1 X254.328 Y368.778

G1 X254.259 Y368.681

G1 X254.231 Y368.543

G1 Y368.447

G1 X254.259 Y368.309

G1 X254.341 Y368.199

G1 X254.452 Y368.116

G1 X254.576 Y368.102

G1 X255.664

G1 X255.802 Y368.13

G1 X255.912 Y368.199

G1 X255.995 Y368.337

G1 X256.009 Y368.447

G1 Y368.543

G1 X255.981 Y368.681

G1 X255.926 Y368.778

G1 X255.816 Y368.86

G1 X255.664 Y368.888

G1 X255.182

G91

M106 S0

G0 Z-3

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X257.7 Y371 F0

G91

G0 Z3.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-3.5

G90

M106 S0

G0 X257.314 Y370.5 F0

G91

G0 Z3.5

G90

M106 S51

G1 X257.245F3000

G1 Y370.321

G1 X257.424

G1 Y370.5

G1 X257.314

G91

M106 S0

G0 Z-3.5

G90

M106 S0

G0 X258.995 Y369.301 F0

G91

G0 Z3.5

G90

M106 S51

G1 Y369.949F3000

G1 X257.975 Y369.976

G1 Y369.935

G1 X258.141 Y369.88

G1 X258.237 Y369.811

G1 X258.32 Y369.715

G1 X258.347 Y369.618

G1 X258.334 Y369.494

G1 X258.306 Y369.398

G1 X258.223 Y369.301

G1 X258.113 Y369.232

G1 X258.003 Y369.205

G1 X257.576

G1 X257.438 Y369.246

G1 X257.341 Y369.301

G1 X257.273 Y369.384

G1 X257.231 Y369.522

G1 Y369.646

G1 X257.245 Y369.742

G1 X257.341 Y369.894

G1 X257.438 Y369.963

G1 X257.576 Y369.99

G1 X257.755

G91

M106 S0

G0 Z-3.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X260.7 Y371 F0

G91

G0 Z4

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-4

G90

M106 S0

G0 X260.245 Y369.866 F0

G91

G0 Z4

G90

M106 S51

G1 X261.995F3000

G1 Y369.935

G1 X260.769 Y370.5

G1 Y369.604

G91

M106 S0

G0 Z-4

G90

M106 S0

G0 X260.314 Y369.274 F0

G91

G0 Z4

G90

M106 S51

G1 X260.245F3000

G1 Y369.094

G1 X260.424

G1 Y369.274

G1 X260.314

G91

M106 S0

G0 Z-4

G90

M106 S0

G0 X261.182 Y368.764 F0

G91

G0 Z4

G90

M106 S51

G1 X260.576F3000

G1 X260.424 Y368.722

G1 X260.328 Y368.654

G1 X260.259 Y368.557

G1 X260.231 Y368.419

G1 Y368.323

G1 X260.259 Y368.185

G1 X260.341 Y368.075

G1 X260.452 Y367.992

G1 X260.576 Y367.978

G1 X261.664

G1 X261.802 Y368.006

G1 X261.912 Y368.075

G1 X261.995 Y368.213

G1 X262.009 Y368.323

G1 Y368.419

G1 X261.981 Y368.557

G1 X261.926 Y368.654

G1 X261.816 Y368.736

G1 X261.664 Y368.764

G1 X261.182

G91

M106 S0

G0 Z-4

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X263.7 Y371 F0

G91

G0 Z4.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-4.5

G90

M106 S0

G0 X263.314 Y370.5 F0

G91

G0 Z4.5

G90

M106 S51

G1 X263.245F3000

G1 Y370.321

G1 X263.424

G1 Y370.5

G1 X263.314

G91

M106 S0

G0 Z-4.5

G90

M106 S0

G0 X264.995 Y369.301 F0

G91

G0 Z4.5

G90

M106 S51

G1 Y369.949F3000

G1 X263.975 Y369.976

G1 Y369.935

G1 X264.141 Y369.88

G1 X264.237 Y369.811

G1 X264.32 Y369.715

G1 X264.347 Y369.618

G1 X264.334 Y369.494

G1 X264.306 Y369.398

G1 X264.223 Y369.301

G1 X264.113 Y369.232

G1 X264.003 Y369.205

G1 X263.576

G1 X263.438 Y369.246

G1 X263.341 Y369.301

G1 X263.273 Y369.384

G1 X263.231 Y369.522

G1 Y369.646

G1 X263.245 Y369.742

G1 X263.341 Y369.894

G1 X263.438 Y369.963

G1 X263.576 Y369.99

G1 X263.755

G91

M106 S0

G0 Z-4.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X266.7 Y371 F0

G91

G0 Z5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-5

G90

M106 S0

G0 X267.995 Y369.811 F0

G91

G0 Z5

G90

M106 S51

G1 Y370.459F3000

G1 X266.975 Y370.486

G1 Y370.445

G1 X267.141 Y370.39

G1 X267.237 Y370.321

G1 X267.32 Y370.224

G1 X267.347 Y370.128

G1 X267.334 Y370.004

G1 X267.306 Y369.907

G1 X267.223 Y369.811

G1 X267.113 Y369.742

G1 X267.003 Y369.715

G1 X266.576

G1 X266.438 Y369.756

G1 X266.341 Y369.811

G1 X266.273 Y369.894

G1 X266.231 Y370.031

G1 Y370.156

G1 X266.245 Y370.252

G1 X266.341 Y370.404

G1 X266.438 Y370.472

G1 X266.576 Y370.5

G1 X266.755

G91

M106 S0

G0 Z-5

G90

M106 S0

G0 X266.314 Y369.398 F0

G91

G0 Z5

G90

M106 S51

G1 X266.245F3000

G1 Y369.219

G1 X266.424

G1 Y369.398

G1 X266.314

G91

M106 S0

G0 Z-5

G90

M106 S0

G0 X267.182 Y368.888 F0

G91

G0 Z5

G90

M106 S51

G1 X266.576F3000

G1 X266.424 Y368.846

G1 X266.328 Y368.778

G1 X266.259 Y368.681

G1 X266.231 Y368.543

G1 Y368.447

G1 X266.259 Y368.309

G1 X266.341 Y368.199

G1 X266.452 Y368.116

G1 X266.576 Y368.102

G1 X267.664

G1 X267.802 Y368.13

G1 X267.912 Y368.199

G1 X267.995 Y368.337

G1 X268.009 Y368.447

G1 Y368.543

G1 X267.981 Y368.681

G1 X267.926 Y368.778

G1 X267.816 Y368.86

G1 X267.664 Y368.888

G1 X267.182

G91

M106 S0

G0 Z-5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X269.7 Y371 F0

G91

G0 Z5.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-5.5

G90

M106 S0

G0 X269.314 Y370.5 F0

G91

G0 Z5.5

G90

M106 S51

G1 X269.245F3000

G1 Y370.321

G1 X269.424

G1 Y370.5

G1 X269.314

G91

M106 S0

G0 Z-5.5

G90

M106 S0

G0 X270.995 Y369.301 F0

G91

G0 Z5.5

G90

M106 S51

G1 Y369.949F3000

G1 X269.975 Y369.976

G1 Y369.935

G1 X270.141 Y369.88

G1 X270.237 Y369.811

G1 X270.32 Y369.715

G1 X270.347 Y369.618

G1 X270.334 Y369.494

G1 X270.306 Y369.398

G1 X270.223 Y369.301

G1 X270.113 Y369.232

G1 X270.003 Y369.205

G1 X269.576

G1 X269.438 Y369.246

G1 X269.341 Y369.301

G1 X269.273 Y369.384

G1 X269.231 Y369.522

G1 Y369.646

G1 X269.245 Y369.742

G1 X269.341 Y369.894

G1 X269.438 Y369.963

G1 X269.576 Y369.99

G1 X269.755

G91

M106 S0

G0 Z-5.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X272.7 Y371 F0

G91

G0 Z6

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-6

G90

M106 S0

G0 X273.526 Y369.701 F0

G91

G0 Z6

G90

M106 S51

G1 X273.664F3000

G1 X273.788 Y369.728

G1 X273.871 Y369.77

G1 X273.94 Y369.839

G1 X273.995 Y369.935

G1 X274.009 Y370.059

G1 Y370.156

G1 X273.995 Y370.266

G1 X273.954 Y370.348

G1 X273.871 Y370.431

G1 X273.788 Y370.472

G1 X273.664 Y370.5

G1 X272.576

G1 X272.438 Y370.472

G1 X272.328 Y370.404

G1 X272.259 Y370.307

G1 X272.231 Y370.156

G1 Y370.059

G1 X272.259 Y369.907

G1 X272.341 Y369.797

G1 X272.452 Y369.728

G1 X272.576 Y369.701

G1 X273.017

G1 X273.141 Y369.728

G1 X273.265 Y369.811

G1 X273.334 Y369.907

G1 X273.375 Y370.087

G1 X273.347 Y370.252

G1 X273.265 Y370.39

G1 X273.099 Y370.5

G91

M106 S0

G0 Z-6

G90

M106 S0

G0 X272.314 Y369.37 F0

G91

G0 Z6

G90

M106 S51

G1 X272.245F3000

G1 Y369.191

G1 X272.424

G1 Y369.37

G1 X272.314

G91

M106 S0

G0 Z-6

G90

M106 S0

G0 X273.182 Y368.86 F0

G91

G0 Z6

G90

M106 S51

G1 X272.576F3000

G1 X272.424 Y368.819

G1 X272.328 Y368.75

G1 X272.259 Y368.654

G1 X272.231 Y368.516

G1 Y368.419

G1 X272.259 Y368.281

G1 X272.341 Y368.171

G1 X272.452 Y368.089

G1 X272.576 Y368.075

G1 X273.664

G1 X273.802 Y368.102

G1 X273.912 Y368.171

G1 X273.995 Y368.309

G1 X274.009 Y368.419

G1 Y368.516

G1 X273.981 Y368.654

G1 X273.926 Y368.75

G1 X273.816 Y368.833

G1 X273.664 Y368.86

G1 X273.182

G91

M106 S0

G0 Z-6

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X275.7 Y371 F0

G91

G0 Z6.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-6.5

G90

M106 S0

G0 X275.314 Y370.5 F0

G91

G0 Z6.5

G90

M106 S51

G1 X275.245F3000

G1 Y370.321

G1 X275.424

G1 Y370.5

G1 X275.314

G91

M106 S0

G0 Z-6.5

G90

M106 S0

G0 X276.995 Y369.301 F0

G91

G0 Z6.5

G90

M106 S51

G1 Y369.949F3000

G1 X275.975 Y369.976

G1 Y369.935

G1 X276.141 Y369.88

G1 X276.237 Y369.811

G1 X276.32 Y369.715

G1 X276.347 Y369.618

G1 X276.334 Y369.494

G1 X276.306 Y369.398

G1 X276.223 Y369.301

G1 X276.113 Y369.232

G1 X276.003 Y369.205

G1 X275.576

G1 X275.438 Y369.246

G1 X275.341 Y369.301

G1 X275.273 Y369.384

G1 X275.231 Y369.522

G1 Y369.646

G1 X275.245 Y369.742

G1 X275.341 Y369.894

G1 X275.438 Y369.963

G1 X275.576 Y369.99

G1 X275.755

G91

M106 S0

G0 Z-6.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X278.7 Y371 F0

G91

G0 Z7

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-7

G90

M106 S0

G0 X279.995 Y370.5 F0

G91

G0 Z7

G90

M106 S51

G1 Y369.742F3000

G1 X279.899

G1 X278.245 Y370.362

G91

M106 S0

G0 Z-7

G90

M106 S0

G0 X278.314 Y369.411 F0

G91

G0 Z7

G90

M106 S51

G1 X278.245F3000

G1 Y369.232

G1 X278.424

G1 Y369.411

G1 X278.314

G91

M106 S0

G0 Z-7

G90

M106 S0

G0 X279.182 Y368.902 F0

G91

G0 Z7

G90

M106 S51

G1 X278.576F3000

G1 X278.424 Y368.86

G1 X278.328 Y368.791

G1 X278.259 Y368.695

G1 X278.231 Y368.557

G1 Y368.461

G1 X278.259 Y368.323

G1 X278.341 Y368.213

G1 X278.452 Y368.13

G1 X278.576 Y368.116

G1 X279.664

G1 X279.802 Y368.144

G1 X279.912 Y368.213

G1 X279.995 Y368.35

G1 X280.009 Y368.461

G1 Y368.557

G1 X279.981 Y368.695

G1 X279.926 Y368.791

G1 X279.816 Y368.874

G1 X279.664 Y368.902

G1 X279.182

G91

M106 S0

G0 Z-7

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X281.7 Y371 F0

G91

G0 Z7.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-7.5

G90

M106 S0

G0 X281.314 Y370.5 F0

G91

G0 Z7.5

G90

M106 S51

G1 X281.245F3000

G1 Y370.321

G1 X281.424

G1 Y370.5

G1 X281.314

G91

M106 S0

G0 Z-7.5

G90

M106 S0

G0 X282.995 Y369.301 F0

G91

G0 Z7.5

G90

M106 S51

G1 Y369.949F3000

G1 X281.975 Y369.976

G1 Y369.935

G1 X282.141 Y369.88

G1 X282.237 Y369.811

G1 X282.32 Y369.715

G1 X282.347 Y369.618

G1 X282.334 Y369.494

G1 X282.306 Y369.398

G1 X282.223 Y369.301

G1 X282.113 Y369.232

G1 X282.003 Y369.205

G1 X281.576

G1 X281.438 Y369.246

G1 X281.341 Y369.301

G1 X281.273 Y369.384

G1 X281.231 Y369.522

G1 Y369.646

G1 X281.245 Y369.742

G1 X281.341 Y369.894

G1 X281.438 Y369.963

G1 X281.576 Y369.99

G1 X281.755

G91

M106 S0

G0 Z-7.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X284.7 Y371 F0

G91

G0 Z8

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-8

G90

M106 S0

G0 X284.769 Y370.5 F0

G91

G0 Z8

G90

M106 S51

G1 X284.603F3000

G1 X284.452 Y370.472

G1 X284.355 Y370.417

G1 X284.286 Y370.348

G1 X284.245 Y370.252

G1 X284.231 Y370.142

G1 Y370.045

G1 X284.245 Y369.935

G1 X284.314 Y369.839

G1 X284.41 Y369.756

G1 X284.576 Y369.715

G1 X284.906

G1 X285.003 Y369.728

G1 X285.072 Y369.77

G1 X285.127 Y369.825

G1 X285.182 Y369.921

G1 X285.251 Y369.825

G1 X285.32 Y369.77

G1 X285.43 Y369.728

G1 X285.692

G1 X285.775 Y369.742

G1 X285.871 Y369.797

G1 X285.954 Y369.866

G1 X285.995 Y369.963

G1 X286.009 Y370.045

G1 Y370.142

G1 X285.995 Y370.266

G1 X285.94 Y370.348

G1 X285.871 Y370.417

G1 X285.788 Y370.459

G1 X285.678 Y370.472

G1 X285.43

G1 X285.32 Y370.445

G1 X285.251 Y370.404

G1 X285.182 Y370.293

G1 X285.113 Y370.404

G1 X285.044 Y370.459

G1 X284.906 Y370.5

G1 X284.769

G91

M106 S0

G0 Z-8

G90

M106 S0

G0 X285.182 Y370.293 F0

G91

G0 Z8

G90

M106 S51

G1 Y369.921F3000

G91

M106 S0

G0 Z-8

G90

M106 S0

G0 X284.314 Y369.37 F0

G91

G0 Z8

G90

M106 S51

G1 X284.245F3000

G1 Y369.191

G1 X284.424

G1 Y369.37

G1 X284.314

G91

M106 S0

G0 Z-8

G90

M106 S0

G0 X285.182 Y368.86 F0

G91

G0 Z8

G90

M106 S51

G1 X284.576F3000

G1 X284.424 Y368.819

G1 X284.328 Y368.75

G1 X284.259 Y368.654

G1 X284.231 Y368.516

G1 Y368.419

G1 X284.259 Y368.281

G1 X284.341 Y368.171

G1 X284.452 Y368.089

G1 X284.576 Y368.075

G1 X285.664

G1 X285.802 Y368.102

G1 X285.912 Y368.171

G1 X285.995 Y368.309

G1 X286.009 Y368.419

G1 Y368.516

G1 X285.981 Y368.654

G1 X285.926 Y368.75

G1 X285.816 Y368.833

G1 X285.664 Y368.86

G1 X285.182

G91

M106 S0

G0 Z-8

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X287.7 Y371 F0

G91

G0 Z8.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-8.5

G90

M106 S0

G0 X287.314 Y370.5 F0

G91

G0 Z8.5

G90

M106 S51

G1 X287.245F3000

G1 Y370.321

G1 X287.424

G1 Y370.5

G1 X287.314

G91

M106 S0

G0 Z-8.5

G90

M106 S0

G0 X288.995 Y369.301 F0

G91

G0 Z8.5

G90

M106 S51

G1 Y369.949F3000

G1 X287.975 Y369.976

G1 Y369.935

G1 X288.141 Y369.88

G1 X288.237 Y369.811

G1 X288.32 Y369.715

G1 X288.347 Y369.618

G1 X288.334 Y369.494

G1 X288.306 Y369.398

G1 X288.223 Y369.301

G1 X288.113 Y369.232

G1 X288.003 Y369.205

G1 X287.576

G1 X287.438 Y369.246

G1 X287.341 Y369.301

G1 X287.273 Y369.384

G1 X287.231 Y369.522

G1 Y369.646

G1 X287.245 Y369.742

G1 X287.341 Y369.894

G1 X287.438 Y369.963

G1 X287.576 Y369.99

G1 X287.755

G91

M106 S0

G0 Z-8.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X290.7 Y371 F0

G91

G0 Z9

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-9

G90

M106 S0

G0 X290.714 Y370.5 F0

G91

G0 Z9

G90

M106 S51

G1 X290.576F3000

G1 X290.452 Y370.472

G1 X290.369 Y370.431

G1 X290.3 Y370.362

G1 X290.245 Y370.266

G1 X290.231 Y370.156

G1 Y370.059

G1 X290.245 Y369.935

G1 X290.286 Y369.852

G1 X290.369 Y369.783

G1 X290.452 Y369.728

G1 X290.576 Y369.701

G1 X291.664

G1 X291.802 Y369.742

G1 X291.912 Y369.811

G1 X291.981 Y369.894

G1 X292.009 Y370.059

G1 Y370.156

G1 X291.981 Y370.307

G1 X291.899 Y370.404

G1 X291.788 Y370.472

G1 X291.664 Y370.5

G1 X291.223

G1 X291.099 Y370.472

G1 X290.975 Y370.39

G1 X290.906 Y370.293

G1 X290.865 Y370.114

G1 X290.893 Y369.949

G1 X290.975 Y369.825

G1 X291.141 Y369.701

G91

M106 S0

G0 Z-9

G90

M106 S0

G0 X290.314 Y369.37 F0

G91

G0 Z9

G90

M106 S51

G1 X290.245F3000

G1 Y369.191

G1 X290.424

G1 Y369.37

G1 X290.314

G91

M106 S0

G0 Z-9

G90

M106 S0

G0 X291.182 Y368.86 F0

G91

G0 Z9

G90

M106 S51

G1 X290.576F3000

G1 X290.424 Y368.819

G1 X290.328 Y368.75

G1 X290.259 Y368.654

G1 X290.231 Y368.516

G1 Y368.419

G1 X290.259 Y368.281

G1 X290.341 Y368.171

G1 X290.452 Y368.089

G1 X290.576 Y368.075

G1 X291.664

G1 X291.802 Y368.102

G1 X291.912 Y368.171

G1 X291.995 Y368.309

G1 X292.009 Y368.419

G1 Y368.516

G1 X291.981 Y368.654

G1 X291.926 Y368.75

G1 X291.816 Y368.833

G1 X291.664 Y368.86

G1 X291.182

G91

M106 S0

G0 Z-9

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X293.7 Y371 F0

G91

G0 Z9.5

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-9.5

G90

M106 S0

G0 X293.314 Y370.5 F0

G91

G0 Z9.5

G90

M106 S51

G1 X293.245F3000

G1 Y370.321

G1 X293.424

G1 Y370.5

G1 X293.314

G91

M106 S0

G0 Z-9.5

G90

M106 S0

G0 X294.995 Y369.301 F0

G91

G0 Z9.5

G90

M106 S51

G1 Y369.949F3000

G1 X293.975 Y369.976

G1 Y369.935

G1 X294.141 Y369.88

G1 X294.237 Y369.811

G1 X294.32 Y369.715

G1 X294.347 Y369.618

G1 X294.334 Y369.494

G1 X294.306 Y369.398

G1 X294.223 Y369.301

G1 X294.113 Y369.232

G1 X294.003 Y369.205

G1 X293.576

G1 X293.438 Y369.246

G1 X293.341 Y369.301

G1 X293.273 Y369.384

G1 X293.231 Y369.522

G1 Y369.646

G1 X293.245 Y369.742

G1 X293.341 Y369.894

G1 X293.438 Y369.963

G1 X293.576 Y369.99

G1 X293.755

G91

M106 S0

G0 Z-9.5

G90

; Cut @ 50 mm/sec, 20% power

M8

M106 S0

G0 X296.7 Y371 F0

G91

G0 Z10

G90

; Layer

M106 S51

G1 Y391F3000

G91

M106 S0

G0 Z-10

G90

M106 S0

G0 X297.651 Y370.5 F0

G91

G0 Z10

G90

M106 S51

G1 X297.775 Y370.321F3000

G1 X297.995 Y370.142

G1 X296.245

G91

M106 S0

G0 Z-10

G90

M106 S0

G0 X297.182 Y369.728 F0

G91

G0 Z10

G90

M106 S51

G1 X296.576F3000

G1 X296.424 Y369.687

G1 X296.328 Y369.618

G1 X296.259 Y369.522

G1 X296.231 Y369.384

G1 Y369.287

G1 X296.259 Y369.15

G1 X296.341 Y369.039

G1 X296.452 Y368.957

G1 X296.576 Y368.943

G1 X297.664

G1 X297.802 Y368.97

G1 X297.912 Y369.039

G1 X297.995 Y369.177

G1 X298.009 Y369.287

G1 Y369.384

G1 X297.981 Y369.522

G1 X297.926 Y369.618

G1 X297.816 Y369.701

G1 X297.664 Y369.728

G1 X297.182

G91

M106 S0

G0 Z-10

G90

M106 S0

G0 X296.314 Y368.612 F0

G91

G0 Z10

G90

M106 S51

G1 X296.245F3000

G1 Y368.433

G1 X296.424

G1 Y368.612

G1 X296.314

G91

M106 S0

G0 Z-10

G90

M106 S0

G0 X297.182 Y368.102 F0

G91

G0 Z10

G90

M106 S51

G1 X296.576F3000

G1 X296.424 Y368.061

G1 X296.328 Y367.992

G1 X296.259 Y367.896

G1 X296.231 Y367.758

G1 Y367.661

G1 X296.259 Y367.524

G1 X296.341 Y367.413

G1 X296.452 Y367.331

G1 X296.576 Y367.317

G1 X297.664

G1 X297.802 Y367.344

G1 X297.912 Y367.413

G1 X297.995 Y367.551

G1 X298.009 Y367.661

G1 Y367.758

G1 X297.981 Y367.896

G1 X297.926 Y367.992

G1 X297.816 Y368.075

G1 X297.664 Y368.102

G1 X297.182

G91

M106 S0

G0 Z-10

G90

M9

M106 S0

G90

; return to user-defined finish pos

G0 X0 Y0 F0