And bed adhesion on 3d printers!

An update…

I have been studying a thread over on the Lightburn forum where Ron Clarke (a pretty sharp 84 yr old  ) describes his work with incorporating PVA glue and water into his TiO2 mix. There have been adjustments made to the ratios and application methods but the ingredients remain largely unchanged… a couple of drops of liquid hand soap were also mentioned. The “recipes”, unfortunately, mix units… milliliters, tablespoons, drops, and even teaspoons!. I can convert easy enough but I’m also trying to mix small batches to test… and his recipes call for larger portions than I want to do right now.

) describes his work with incorporating PVA glue and water into his TiO2 mix. There have been adjustments made to the ratios and application methods but the ingredients remain largely unchanged… a couple of drops of liquid hand soap were also mentioned. The “recipes”, unfortunately, mix units… milliliters, tablespoons, drops, and even teaspoons!. I can convert easy enough but I’m also trying to mix small batches to test… and his recipes call for larger portions than I want to do right now.

That said, I did mix a roughly 2:1 ratio of PVA to water and added a slightly-heaping “real” table spoon (need to get some of the real measuring devices) of TiO2 to the mix. I shook it as good and long as I could… even used the drill motor “shaker”. The result was thin enough to spritz/spray onto a tile but had a lot of little bubbles (from the shaking, I’m sure)… but it actually was trying to "self-level" so I helped it along with a foam brush and my shake table. Except for the bubbles, it looked pretty good.

The good news is that it dried beautifully to an evenly-coated semi-gloss painted surface… with no bubbles and with no cracks in the finished surface.

The bad news is that I didn’t get enough TiO2 powder into the mix…

Now the problem is that adding more TiO2 to the existing mix made it thicker and harder to mix. Adding water to thin it back down, I was able to get a spreadable mix again but the result was that it really didn’t change the resulting image… it looked virtually the same. No clue why the added TiO2 apparently never really made it to the surface… and now my ratios are all basically unknown.

I’ve reached my limit for the day. I am excited about the potential of this "Ron Clarke Method"… it’s far more economical than spray paint, not smelly during lasering, and cleans in seconds with a brush and water. Tomorrow I’ll try to mix a new batch from scratch and take care to mix carefully as I go. The PVA glue is so thick it’s kinda hard to measure out and then get all the contents into the bottle without adding a bunch more water… maybe I can mix half the water and TiO2 together first and then add the PVA glue and remaining water.

– David

I wonder if you could mix the TiO2 powder into paint reducer for airbrushes, or something like the Flowtrol reducer for house paint from The orange depot. I believe that its possibly a paint base without the color additives. I’m not sure how long it would stay in suspension though. you might need to continuously shake the mixture.

Maybe this method isn’t that great for spray application. Maybe you could get better results mixing your recipe thicker and applying with a small roller.

@dkj4linux This was my first thought as well.

I came across a couple techniques for powder coating non-conductive materials such as wood or glass that you could possibly adapt to this but not sure if the TiO2 powder will react the same way.

The other thought I had was to corona or plasma treat the surface to improve adhesion but you would need the equipment.

The last thought was to screen print your alcohol/TiO2/PVA solution to get a more even application. I think this could work really well since it would be a more viscous solution but you would have to play with the recipe to get the viscosity right.

All your laser posts have motivated me to buy one so I can join in the fun so keep them coming! That goes for the rest of you guys too. ![]()

If you want an overboard solution. Maybe there is a way to mox the powder with the air assist. Then you don’t have to pretreat the tiles. It would be like laser sintering.

While I genuinely appreciate all the suggestions – I really do! – I feel compelled to keep everything as simple and accessible to as many folks as possible; i.e. as always, KISS is king! I am convinced that this Ron Clarke Method of using raw TiO2 powder will be the most inexpensive, quick, and safe way to pre-treat ceramic tile for lasering and handling. I really don’t think the application method – spraying, brushing, and/or whatever – is gonna be that big a deal as the simple “shake table” should level it all out if the texture is right.

I will admit to some level of frustration trying to zero in on a decent and foolproof “recipe” (I’m totally out of my element fumbling and messing around with "kitchen math and gadgetry"… I don’t cook either!) but feel we’re getting close. But, to top it off, I’ve been sidetracked today setting up my new Chromebook (got it this morning!) and getting all my Linux apps (Lightburn, PrusaSlicer, OpenScad, etc) going… so have made virtually no further progress on this project.

Oh well…

– David

I’ve been seeing this thread, and thinking about it every now and again. Ultimately, it sounds like the best results would be a fine, even coat of dried TiO2 on top of a clean ceramic tile. No binder, no extra residue. Barring that, you’d want something that the laser will burn off very quickly (and hopefully cleanly). So if you use PVA glue, water it down as much as you can, adding in a drop or two of surficant (or whatever) to break up the surface tension, and allow it to evenly coat the tile (as best you can). What I might be tempted to do then is, instead of working really hard to mix in the TiO2 powder, I’d just get the tile coated with my binder, then use a sifter or cheesecloth or something to dust the tile with the powder. Let it dry, gently knock off any excess powder, and go to town.

But that’s just my brain spinning while I wait for software to load on a Pi…

Alright… back at it this morning.

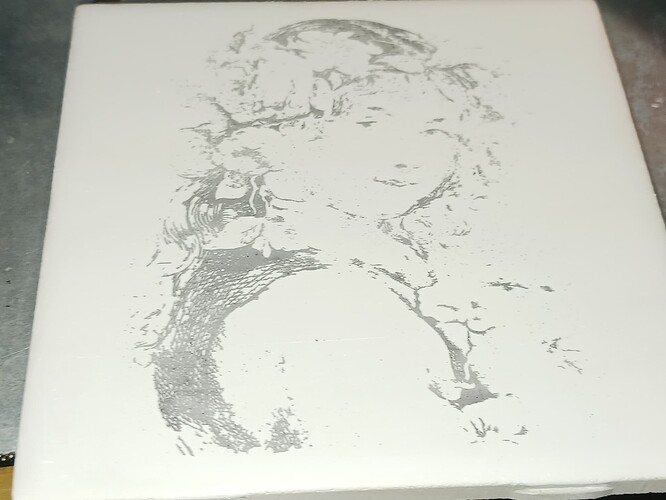

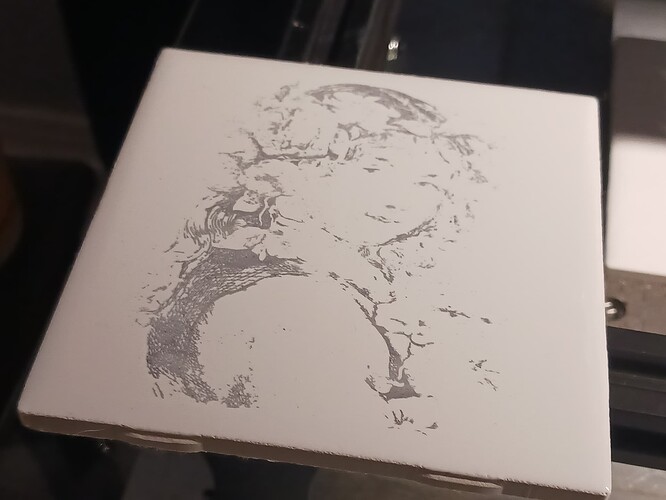

Mixed a new batch of TiO2 mix and got encouraging results. I need to thin the mix a bit more to try to even out the coating but otherwise it’s starting to look pretty good…

The “recipe”: I used a small cough syrup dosage cup to represent 1 part. By volume, add 1 part water to 2 parts TiO2 powder in small jelly jar. Swirls into solution without lumps or stirring. Add a few drops of Dawn dish-washing soap. Add PVA glue to double the previous volume (easier than trying to measure it out in parts!). Then add 3 parts more water to approximate viscosity.

I brushed on the mix and it dried with no cracking…

Nice black engraving indicates decent TiO2 percentage… though slight banding comes from uneven brush stokes…

Finished tile… nice, but no cigar

Gonna check with daughter about food coloring… could probably use coffee in place of water?

Later.

– David

All,

My sincerest apologies to all – and especially to Robert – for hijacking his thread. He’s started a second thread… showing ever more spectacular results, using new technigues, and of interest to us all. This further work should rightfully belong to this thread… which I’ve thoroughly made a mess of.

I’m truly a fan of Robert’s work and sick to see, in retrospect, how disrespectful and intrusive I’ve been. I noted how graciously he gave me “likes” as I posted about the TiO2 stuff, that several had said was on your “radar”, and I mistakenly took that as encouragement to keep posting here. I know now that was not right… I should have started a new thread.

Again, my sincerest apologies. I truly love Robert’s work and feel terrible for interfering with it.

– David

David PM me the same message, and here is my response:

David, I have zero issues with you continuing to post on my previous thread. In fact, my tub of titanium dioxide arrived this afternoon, and perhaps in the coming days I’ll have something to contribute to the discussion. I’m really hoping you get something figured out on how to use it successfully. If you hadn’t noticed, I’ve liked most of the posts you’ve made on that previous thread.

I started the new thread partly because Ryan encouraged people to do it that way if there was any chance the post would be used in the gallery. Apparently, there is some limitation about only one image from any topic can be used in the gallery.

If you hadn’t noticed, I’m a big fan of your work and your support of this forum. Keep it up.

So, David (or anyone) you are more than welcome to continue the TiO2 discussion here.

When my bucket of TiO2 gets here, I might do that…