Since everyone who’s spoken up so far has the TiO2 powder on their “radar”, so…

I’m not a “chemist” or a “chef” so I’m trying, of necessity, to keep this as simple as I can. The simplest “recipe” I’ve found is a simple 3.5:1 ratio of ethanol to TiO2… and I’m believing denatured alcohol should be an okay substitute for the ethanol. And I’m using a simple spray bottle to do the application of this mix to the surface of clean white ceramic tiles. I really want to avoid trying to learn how to “paint” with an air-brush.

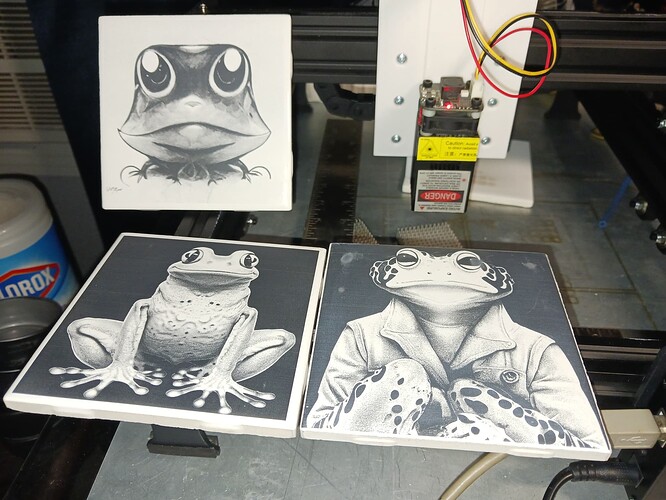

First, I simply sprayed as fine a mist as I could… one or several coats, same result. Left undisturbed to itself it left a uncontrollable rough surface (left) compare to spray painted tile (right)…

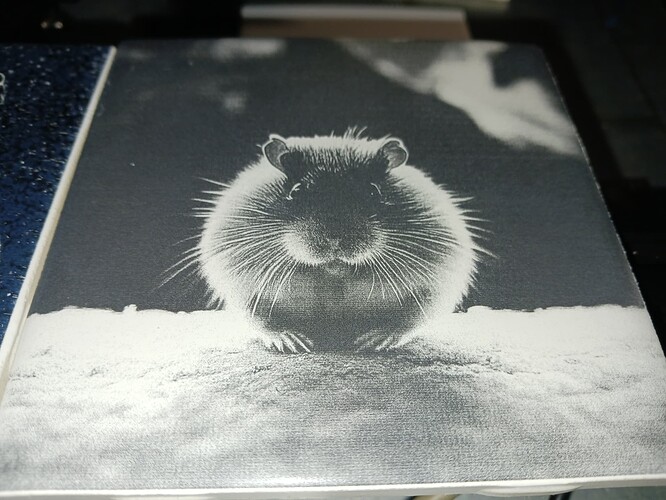

and, as we’ve seen, resulted in a equally rough texture to the tile and image…

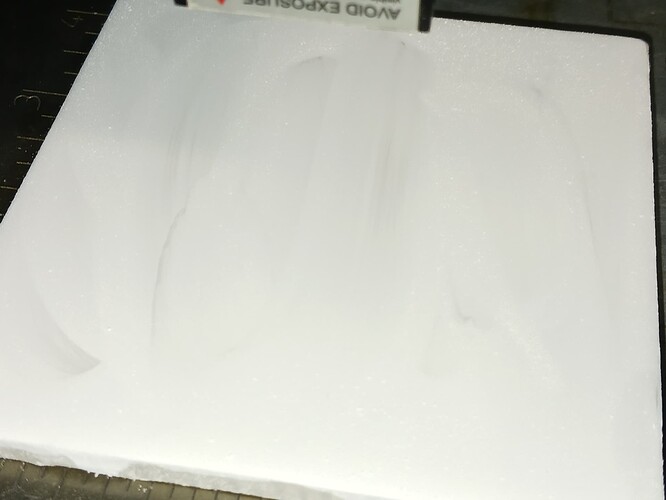

Next, I tried spraying on a rather heavy coat and then light brushing it to try and level out the coating…

Note that once dry the powder can easily be scraped/scratched off… and quite likely the “furrows” left from brushing the surface might have cleared the powder from the surface of the tile. Predictably, I got these images…

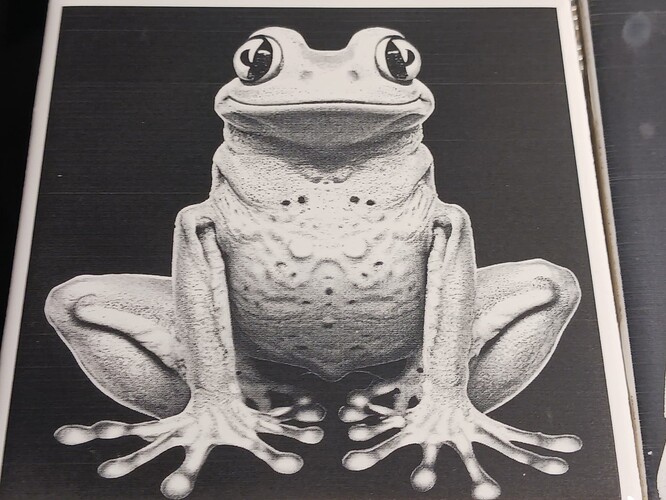

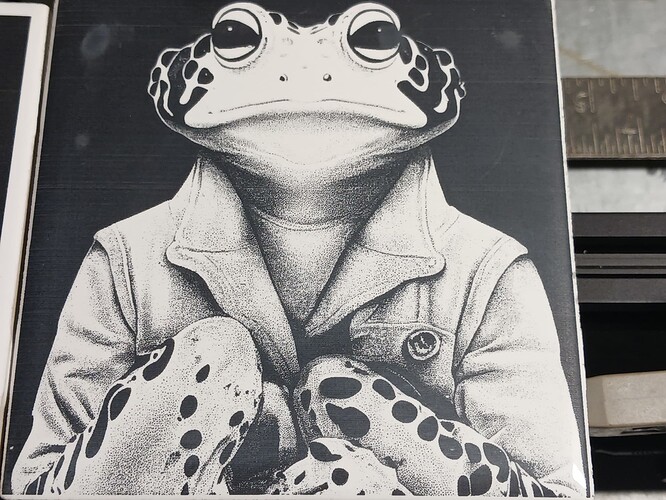

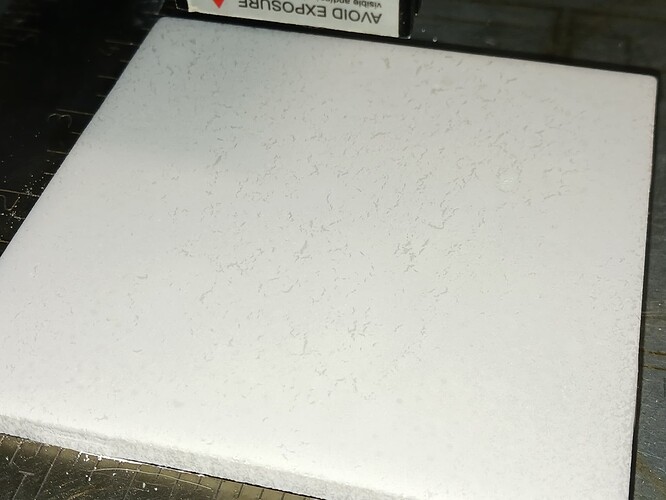

Finally, as I write this , I’m lasering a tile that I simply poured some TiO2 mix in the center of the tile and then spread it around lightly with the tip of my finger… ungloved, of course

Obviously, the thickness of the coating is heavier in some spots than others… but I think there is a coating of powder, of some thickness, over the entire surface.

Sneaking a peek at the lasering process… it’s looking better though it appears that maybe the heavier “banana-shaped” coating just off the top-back of her shoulder may not be lasering completely through…

I’m sure that it’s the ungloved finger that’s made the difference… and maybe licking my finger clean will take it to the next level ???

BTW the completed tile looks like this…

Obviously, the heaviest areas didn’t laser through, and left light/blank areas, so we really need to figure out a way to level out the coating. Anybody got a simple spin fixture design, ready to go?

– David