These are good questions. Never apologize here for asking questions, it’s how we learn and teach and for every question asked there are many more folks reading along in silence that can also learn from our discussion.

No, if I were using two power supplies I’d have a specific wire that went from the (-) on one power supply to the (-) on the other power supply. Each power output would then run to the load with its’ own twisted pair wires.

No, I would not do it that way.

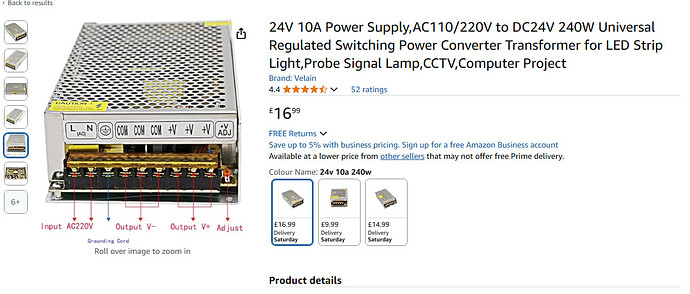

First, an LowRider kit power supply is not sized for running the LowRider and also a laser module. If I were using 24V power for both laser and Jackpot (LowRider), I would get a single 24V power supply sized with some headroom above the max expected power of both loads combined.

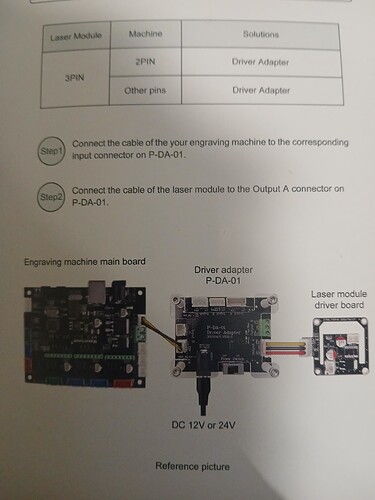

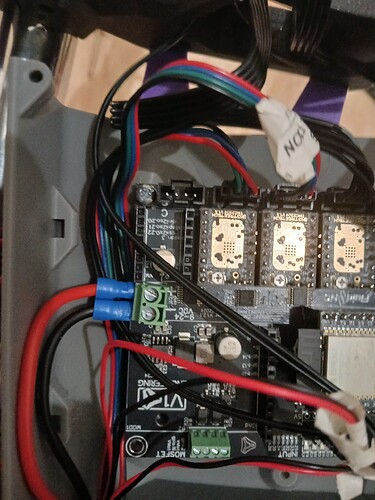

If I were using a 24V laser module, I’d connect one twisted pair 24V cable to the jackpot and run a separate 24V twisted pair from the power supply to the laser module.

The control signals from the jackpot would be a separate wire bundle that joins up with the power supply wiring going to the laser module.

I would not use the low side switched FETs on the jackpot to power the laser module in any event.

I would not use a phone charger for anything related to the CNC.

There are lots of options, and to make confusion worse, there are really bad marketing gimmicks used by laser sellers. Some will list optical power (say 10W) and some will list input power (say 40W). You might be tempted to think that the 40W input power module is much higer power, but it may turn out that it only has 9W of optical power and may have a really crappy stacked diode and lens setup.

So, doing your research is key, and getting a module from a reputable supplier is also key.

You will also find that the laser module you get will be different for engraving vs cutting. For engraving you want as small a dot size as possible with decent optical power. For cutting, then you want enough power to cut through your material.

All of this is a discussion, and we’d be happy to keep having the discussion.

Those of us that have lasers can comment further. I’m pretty happy with my NEJE brand lasers, others here will have other brands they are using and trust.

I’d pick a laser module first for my application, and then deal with deciding on the electrical interface decisions you’re discussing.

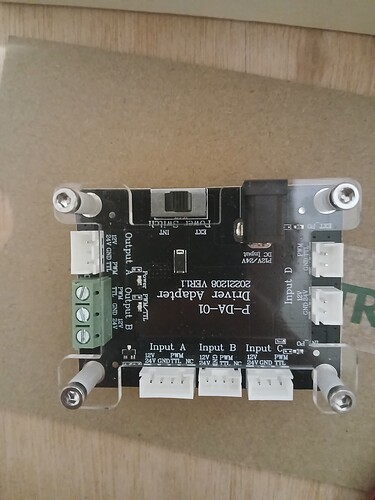

We haven’t yet talked about whether your laser module will come with and need an adapter board- so that will be part of the discussion as well.