What he said!

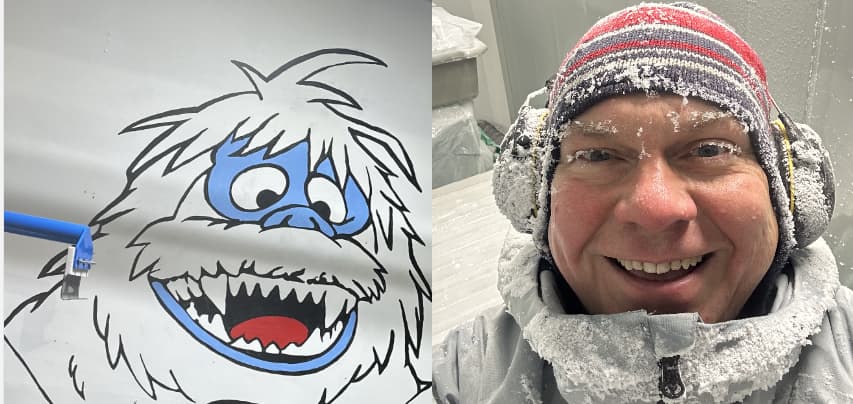

You don’t look like your profile picture (says the mole)… ![]()

I just pulled it off so I could see things. It may or may not be required on this machine. If I’m only ever doing snow filled cube engravings maybe it won’t need collection (the snow packs right back into the cut very tight). However when doing carves for logos that are to be filled with color - like the larger tabletop kinda logos - I think I’ll want to try the dust collection. I don’t know how well it’ll work to be honest - the snow tends to stick a bit and could very well gradually build up in the vac hose to the point it plugs up anyway.

We’ll see!

Ah, interesting! I was just joking around, but that makes sense. My dust collector wouldn’t love ice, but I guess a shop vac would be perfectly happy with all the water!

That is an amazing step! I remember meeting you for some pizza and you told me you were going to do all of this. It’s great to see it come to fruition.

That looks like an incredible space. I love the theme. A sneaky eagle carving in there too looks amazing.

I don’t know about the health and safety issues with this, but for ice sculptures, maybe try blasting the chips out with compressed air instead. The air might even be cold coming out of the nozzle and help keep things sold. You would have to handle the surface finish, since the ice chips could fuse back to the mother ice.

After engraving the logo would you normally cut each one out as a cube?

This is so exciting to follow along with!! I love the videos. I bet I could follow your settings and whip up a few cubes of my own to cheers you with!

No need for that! I’m going to mail you a few.

And here I was gonna go all ghetto and use a Ziplock. The freezer one of course. That would work, right?

You are absolutely correct. The “big guys” use a tool change on the CNC to cut the cubes afterwards but I prefer the marketing angle of being “hand cut” (on a saw). And I don’t have a $20,000 CNC machine.

Because I don’t need one! I’ve got V1 machines!

I have yet to find a pizza even close to that place.

I wonder if I wrapped the vac hose in heat tape if it would melt the snow well enough to turn to water. I feel like the incoming cold air would prevent that.

We’ll cross that bridge eventually here.

Compressed air to blow it out of the cuts instead of using a vac? I would think it would stay frozen and you would just have a small snow drift to clean up somewhere.

That was the solution when I was using the MPCNC for the ice but not for the same reason. I don’t know if you recall but the snow packs in behind the bit so hat it’s almost as tough as the ice. So on a deep carve (multi z step down) if I didn’t clear the cut it would actually eventually start making the steppers skip. And I don’t mean just the first few passes. EVERY pass had to be cleared. If I went in a total of an inch and a half at half inch steps the final pass would make enough snow to completely pack in the entire depth of the cut.

I started chatting on the forums about a solenoid valve or something like that to pulse the air but never pursued it. Now with the aluminum cutting happening and these misters to spray ISO I think it may be worth another look for the LR32 (which is still being built but is paused while I contemplate just abandoning it and building up an LR4 instead).

If it does need to be that clear something like a small copper tube bent to flow directly down the bit.

I have a gut feeling an air blast is going to be needed and more so than a vac with a good dust shoe, the combo might be good as well but it depends on how much snow you are making.

As much as I would love to see a LR42, This one is done, beautiful, and ready to rip. Let this one do some more work and pay for a LR4

I’ve got everything here for the second LR3 already (board, steppers, all nuts and bolts etc). I’ve even got all the parts printed waiting for me to have time to…do some post processing. So the LR4 would only be a matter of some more printing and a flat rate shipping box from a guy I know with some aluminum plates…I think the “post processing” I had in mind for the LR3 would work equally well if not better on the LR4.