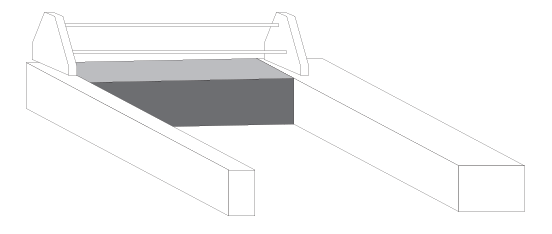

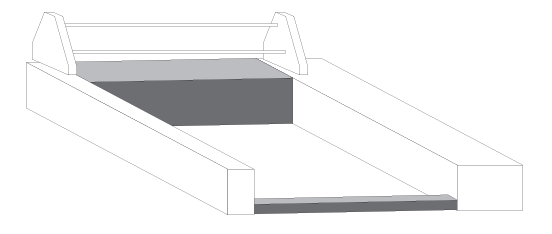

I’ve no need for the “home docking station” anymore. The end goal/machine use would be to set it right on the ground (or on a tabletop/work surface/back of my truck) and plop a slab of ice measuring 20" wide X 40" long. These slabs would have varying thicknesses but never less than 2" and never more than 9". I’d adjust the height accordingly through something simple like quick-attach blocks or screw feet or something. Some quick clamping method to make sure the slab of ice and the machine are “one” (so the ice doesn’t slide around under the cutter) and off she goes.

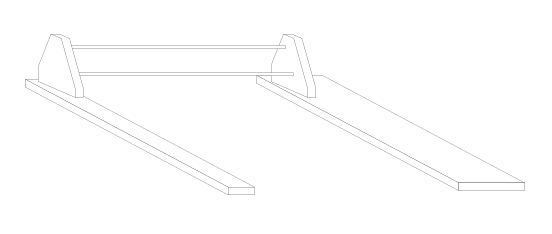

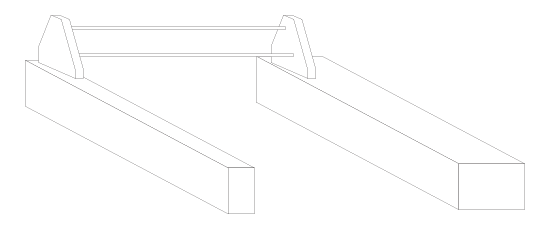

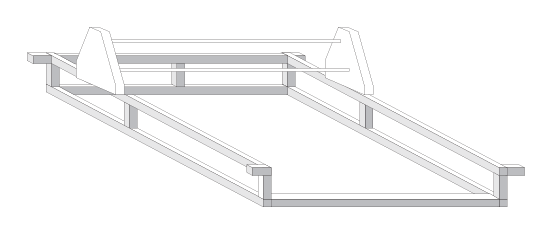

In looking at the actual needs of the LR3 there are two basic absolute requirements - the left and right surfaces.

Now, I need something that’s at least got room for a 2" thick slab.

And to hold it together I could bridge it at the back of the machine much like the Bumble is bridged. Truly there’s no need for the “box” there but these drawings aren’t actually about building a boxed assembly - just to communicate my thoughts here.

Unlike the Bumble machine I do not have a “floor” in this inner area so to stiffen the assembly I’d just tie the front end of the U together with a strut.

And that’s where I’m sitting. My thinking is to use extrusion (because I have some laying around and someone local has a bunch more on Marketplace at the moment). It seems to me that extrusion is lightweight, can be assembled flat and square, and SHOULD be something a guy can disassemble and reassemble reliably? Am I right so far?

I’m searching for the most minimalistic build possible here to keep weight right down for portability, perhaps some “knock-down” assembly method like maybe the front strut comes off and the back bridge disconnects from the two rail wings?

I saw this last night

and those side-attached standoffs for the belt mounts really got me thinking I could minimize it quite a bit…maybe something like this:

What thinks the collective here?