You heathen! I am shocked. ![]()

Red can easily be removed with heat. I usually heat my soldering iron up and touch it to the end of the bolt for a few minutes, then crack the bolt loose while hot.

I know this isn’t what you meant, but we actually used to have ducks here, well my daughter did. And yes they are always watching LOL

I knew it could be removed with heat but never once thought about the soldering iron. I had flame in my mind lol. Hopefully they are good and don’t need to be removed lol

Torches are a lot more fun than soldering irons…

Torches don’t work well when trying to remove a grub screw from a stepper motor or a set screw on the side of a throttle body (Looking at you Harley Davidson… grrrrr)

Somewhere in my garage I have a 1/4" socket screwdriver with a 75W soldering iron heater, and a matching set of allen key wrenches

Oh wow. I didn’t know anything like that existed. After fighting and losing with grub screws on my old hemera hot end I picked up a set of these…

https://www.amazon.com/gp/product/B07X443PFF/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Hopefully they come in handy if I ever need them lol

Was this DIY or an actual product? It sounds like something I’d try.

100% DIY.

The 2, 2.5 and 3mm keys are discoloured from the heat, they’re standard 1/4" drive bits. It’s hackish, but it works. Ain’t pretty tho.

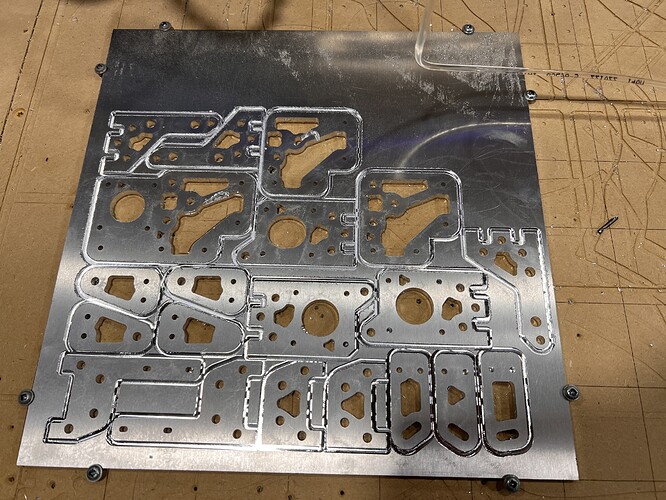

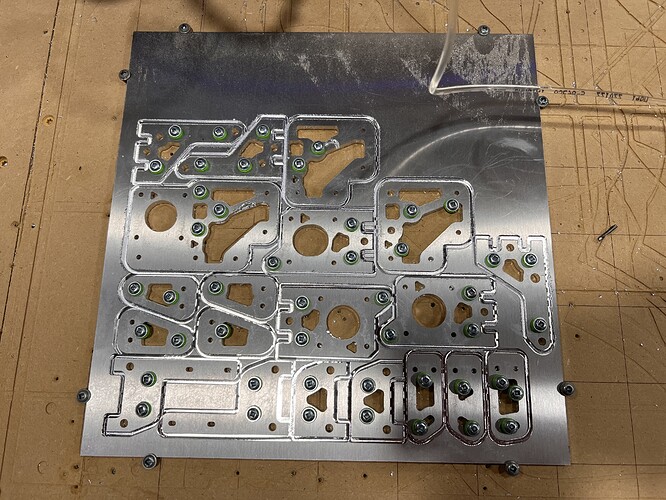

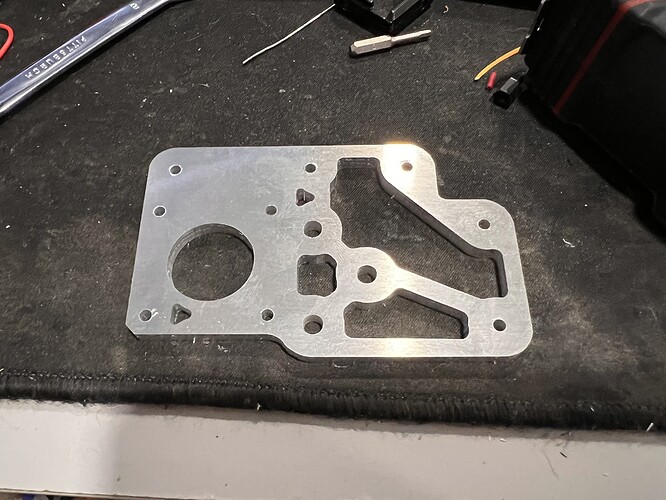

Well time for another update!

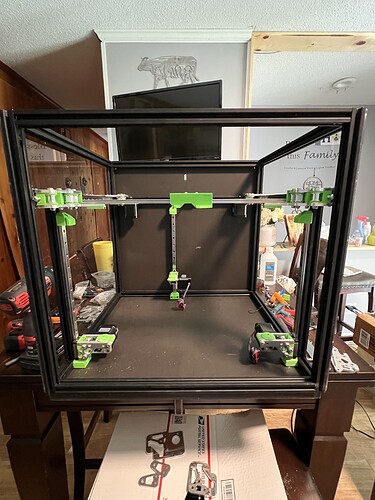

Got all the parts swapped out for a new set that’s not nasty spray painted lol. These look a TON better. Pics don’t do the difference justice that’s for sure!

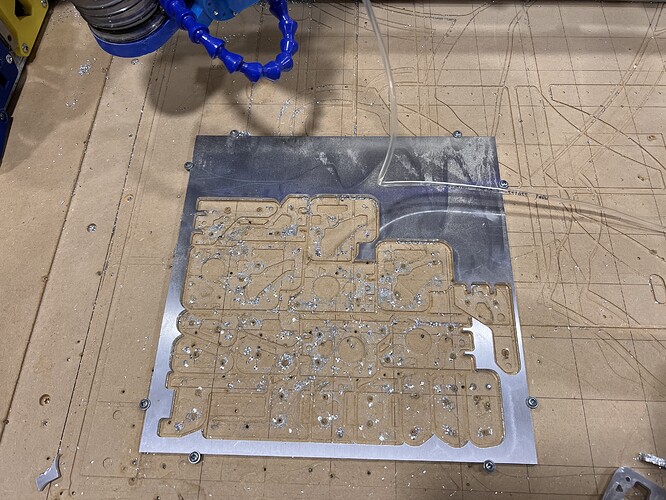

Got the side panels, bottom and back panel cut and installed. Have the DXF files ready for a front and top “open” panel that will stay on all the time. And I have plans to come up with a track that I can slide another sheet in the front and top to enclose for when the need arises. I don’t want to deal with doors and lids all the time when 99% of the time I’m printing PLA. Oh forgot to mention the clear panels are 1/8" polycarbonate from good ole amazon. Plywood is some left over 3/4" Birch. Way thicker than I needed but its nice to be able to run a 1/2" screw in and not even have to think about if its going to come out the other side.

Also I spent a lot of time looking over and thinking about the back panel before I cut it. I really wanted all the wires able to come through cleanly and neatly. I’m pretty sure I managed that, but we will find out here soon.

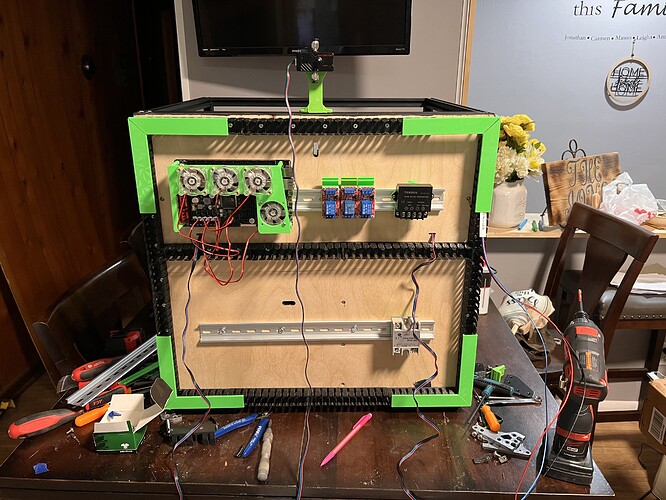

Also started working on the electronics area. I bought some cable duct off amazon but I didn’t pay attention to the size of it well enough and I just wasn’t happy with how big it was. @Michael_Melancon was nice enough to point me in the direction of the Voron cable duct so I printed that out and got it installed. Much better size wise that’s for sure!. Also got the din rail mounted. I’m short 1/2 a piece of wire duct so waiting for that to get done on the V4 now then it will be time to start running wires!!! I’m shooting for a real clean build. I absolutely hate how the wiring is on the V4. And I refuse to let the V5 become the same mess. So no wiring things “temporary” to make sure it works, because I know once it does I wont want to take it back apart to fix it. Hoping to get a little bit further with the wiring tonight. Tomorrow is a lot of Doctor’s appointments and running around but hopefully tomorrow afternoon/evening Ill be able to take another big stab at it.

Still a few filler pieces to print but it’s coming along nicely I think

Looking good!

Thanks for testing those cable trays before I tried to print them ![]()

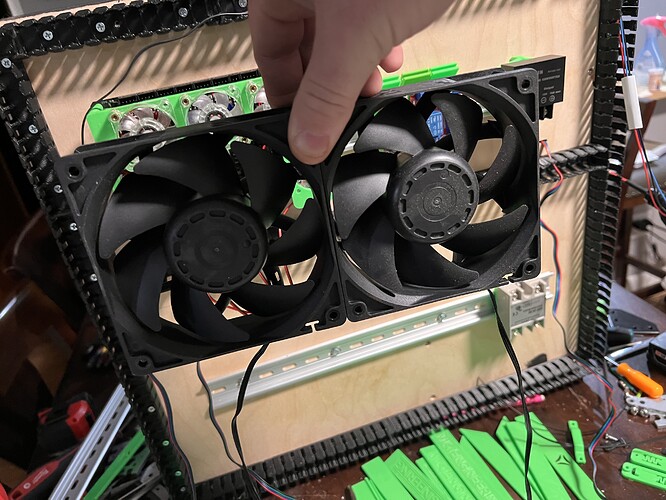

Are you sure you have enough fans on those stepper drivers?

LOL you’re welcome! Thanks for the idea! That reminds me I have to setup a return to amazon for this other stuff lol

Was planning to mount these to feed the smaller fans…

Totally kidding. That was a mount I found on printables for the M8P and I had a pack of 4 fans. Blindlessly hooking them up while thinking about other things lol

One isn’t even over any drivers lol. The CB1 fan will come in handy and I just like knowing there is air moving over the stepper drivers. Hoping I can set them to about 50% or less anytime the steppers are active

so the first set of aluminum parts were just ugly - but dimensionally accurate? Seems like you could donate those to some poor soul who really really wants to make one of these, but is less fortunate. How hard would they be to anodize a cool color? or bead blast them to get a more matte finish.

I tried to experiment with the first set of parts and I did NOT like the result. So then I primed and painted them and that looked like hammered dog ![]() too. So that’s when I just made the second set. My plan is to take all the paint off of these and pick up a harbor freight powder coat setup and give that a shot. All of these parts are small enough to do in a used toaster oven so it seemed like a good learning opportunity. If you still want them after I’m done with that then you are welcome to them. But there will be quite a bit of delay. The powder coat wont happen until next time I’m home which is May, and I wont even begin to guess at what point I’ll actually be able to get to it lol.

too. So that’s when I just made the second set. My plan is to take all the paint off of these and pick up a harbor freight powder coat setup and give that a shot. All of these parts are small enough to do in a used toaster oven so it seemed like a good learning opportunity. If you still want them after I’m done with that then you are welcome to them. But there will be quite a bit of delay. The powder coat wont happen until next time I’m home which is May, and I wont even begin to guess at what point I’ll actually be able to get to it lol.

Oh, I wasn’t asking for them, just got home from a “feed my starving children” packing session and was thinking about the poor starving children around the world and tossing your “perfectly good parts” when there are probably others that could use them - would be a waste.

Powder coating sounds like a good idea and will be interesting and educational to try. I’m building mine with acrylic when I get sick of how slow the v4 is and once I get the cnc rebuilt I’ll cut my own aluminum v5 set, which is probably more of a bucket list item for the mpcnc now as a rite of passage than anything else. I dig your build though. Thanks for sharing.

Man once I finally got all my issues on my V4 squared away and put a better hotend/extruder on it its anything but slow now. The V5 should be faster, but I wouldn’t call the V4 slow, not anymore anyways LOL

Can you please post your F&S settings? And a link to @vicious1’s suggestion?

Man you all are killingme!