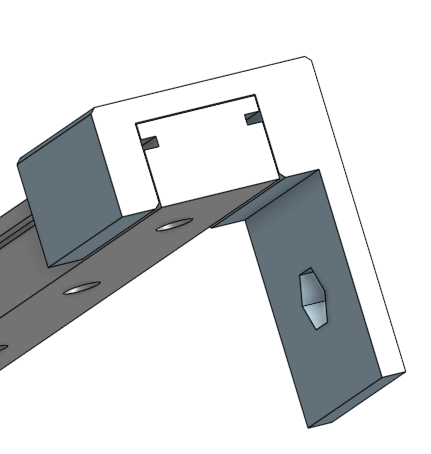

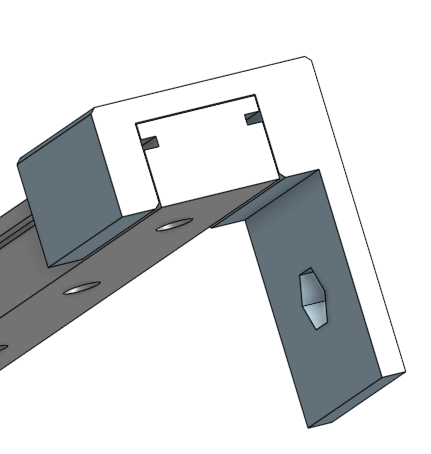

ok, I added a new part to the CAD model called “y rail aligner”… print two and call me in the morning. orientation of the print should have the part lie on the bed like an L for better dimensional accuracy.

ok, I added a new part to the CAD model called “y rail aligner”… print two and call me in the morning. orientation of the print should have the part lie on the bed like an L for better dimensional accuracy.

And, how tight do you make the coreyx tension? Is it possible I have it too tight? It seems like most of the resistance is coming from the idlers, which were spinning freely when I didn’t have the belt attached.

I am going to see how it feels with a little less tension.

It took me a while to get sensorless homing working on my 3DR Frankenstein 3DP. It uses a duet 2 WiFi so the firmware is different but I learned a lot that should apply to marlin as well. Some key knowledge I gained:

If you want I can share the GCode files I built for homing but they wouldn’t help in marlin. I could also share the online documents on the duet website that explain it all.

But here is the idea of what I did during homing

All of that was super easy to do on the duet. It’s just GCode in files named homeX.g , homeY.g, homeAll.g. Not sure if it translates into marlin as easily.

Those are all configurable. Why bother changing the sg sensitivity though? I think it only notices while homing in Marlin.

yes, it is possible to have it too tight. the M5 bolts that go through the corner plates and xy brackets should be tight when the belts are loose. If not, that’s another possible cause of problems since it let’s the idlers move off-axis in unhealthy ways.

Also, I use reversed lock-nuts on the bottoms of the M5 bolts that carry idlers. Why? because the inner diameter of the lock nut is small enough not to interfere with the idler. And because lock nuts.

I can try that. I tightened the with the fat side towards the idlers. I tightened them until the idlers didn’t spin and then backed off 1/8 turn. They were all spinning freely before I put the belts on.

On the duet and Prusa version of marlin there is a GCode command something like M916. I think that’s it. And I am not sure if it is in the main marlin branch. With it you can set the SG sensitivity between -63 and +63. Default is 3. Lower number is more sensitive. +63 is basically turned off. You can also set the minimum speed filter for it to work at all. Default is 200 steps per second. Yeah it counts Full steps not feedrate (strange). I am pretty sure this setting works during homing and normal printing. I have used it on my Prusa and this duet now during prints. I am not familiar with any other sensitivity setting that is only used during homing. And the numbers you mentioned earlier are well out of the range for the M command I am talking about.

Anyway I used that to change the sensitivity during homing but I really didn’t need to. I could have left it all as default. But then I would have needed to lower my stepper current even more because it was crashing into home and not tripping the stall guard during homing. It was just a trial and error thing until I ended up with Numbers that worked for me with cold and warm steppers.

It’s also a good idea to set the stepper power to a lower setting while homing. At least that way when the bltouch’s probe doesn’t deploy(it will do that sometimes) you don’t bend the X axis rail, or break the hot end mount.

I have 2209s. For some reason it is 0-255. It is the same command. I was jogging fine with a sensitivity set to 140. Then I tried to home and it immediately triggered. I had to drop it below 90 before it would make it to the end of travel. So it was probably triggering while jogging around. But my point is, it doesn’t matter. Unless you have hardstops enabled. I am not trying to argue, and you are helping me, so I appreciate it. I was just thinking that through.

Hmmm. I have been using two bltouches for a while on my other printers. That hasn’t happened to me. I have had it fail to trigger, but it has always been a broken mount or something that was my fault.

I’ve had a couple fail to deploy, also if you’re too close it will fail to deploy because it can’t deploy. Sometimes that triggers a fault, sometimes it doesn’t. Usually it’s because it gets covered by petg cobwebs that get blown off by the part cooling fan.

Either way, I think dropping the current is a good idea.

Not my video, but same printer, shows what a corexy can do.

I owe an update. I am not going to get to print something today. I am real close, just the heaters and thermistors to wire up. I’ll hopefully get that done tomorrow.

Look what came in the mail yesterday! Serial number 1. I love it.

I have been working on the wiring. I reversed again and put the bed mosfet back in. It just fits.

I got the whambam pei build plate too. Looks great.

I’m a but worried about this, otherwise, this bed seems awesome. I may put some kapton down, and then also print something to cover that, although it might not last long on the bed.

I’m quite pleased with the wiring. There is extra motor wires under the controller, but I managed to keep the top of the controller pretty clear, and I only had to make a few wires.

The spool mount looks pretty awesome.

I am super excited to finish the software and feed some filament through. I won’t have much time for a few days though.

Dude, that’s nice looking!

OHHHHHHH!!! Yes, Looks pretty dam slick so far!

Not too bad, considering I still have quite a few tuning steps to go (bed leveling, temperature, extrusion, slicer settings, especially retraction).

Try a bit of silicone calking on those solder joints. That should be able to handle the heat and will look better than Kapton tape.

with a bowden drive, you definitely want to enable linear advance (k-factor) in your marlin build and then figure out what it is for your system. mine are all around 35-40.