Tomorrow I can swap the one from the other LR3 and see if that makes any difference… Should I put the RS485 card back in when I do??

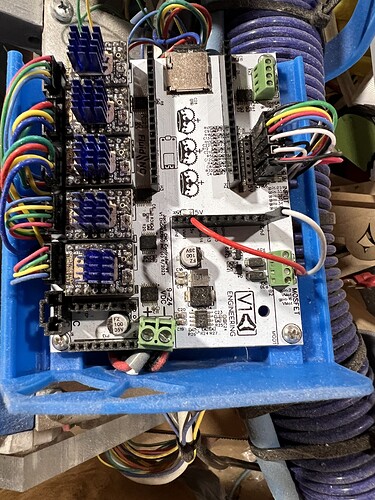

Made an hour long cut with it last night. All steppers around 35°C according to the stick on temp gauges and by touch I agree with them. Noticeably cooler than with the SKR and them running around 50°C

I’m about to run the same cut again but I’m going to swap in the ESP32 from the other LR3, Put the RS485 back in and see if it acts the same way or not. Will report back.

Something isn’t right. When you boot try $SS in the terminal and paste the results here.

Sounds like your drivers are not booting right. Your steppers should have a little more heat than that with your settings cranked up. Mine are a bit hotter on stock settings, and the shop is about 67F. The 4.7k pull up would probably help here.

Sorry didn’t see this until now. Cut just finished and everything went great! Had my spindle control and all LOL.

Here is a pic of the steppers after 1 hr cutting…

Y1

Z1

X

Current temp 7’ above the CNC

Y2/Z2 were the same.

After a fresh reboot this is what I get from $SS

$G

<Idle|MPos:40.000,830.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P|WCO:0.000,0.000,-54.060>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P|Ov:100,100,100>

$SS

[MSG:INFO: FluidNC 3.7.10 https://github.com/bdring/FluidNC]

[MSG:INFO: Compiled with ESP32 SDK:v4.4.4]

[MSG:INFO: Local filesystem type is littlefs]

[MSG:INFO: Configuration file:config.yaml]

[MSG:INFO: Machine LowRider]

[MSG:INFO: Board Jackpot TMC2209]

[MSG:INFO: UART1 Tx:gpio.0 Rx:gpio.4 RTS:NO_PIN Baud:115200]

[MSG:INFO: UART2 Tx:gpio.14 Rx:gpio.15 RTS:gpio.13 Baud:9600]

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P|WCO:0.000,0.000,-54.060>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P|Ov:100,100,100>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P>

<Idle|MPos:0.000,0.000,0.000|FS:0,0|Pn:P|WCO:0.000,0.000,-54.060>

$SS

[MSG:INFO: FluidNC 3.7.10 https://github.com/bdring/FluidNC]

[MSG:INFO: Compiled with ESP32 SDK:v4.4.4]

[MSG:INFO: Local filesystem type is littlefs]

[MSG:INFO: Configuration file:config.yaml]

[MSG:INFO: Machine LowRider]

[MSG:INFO: Board Jackpot TMC2209]

[MSG:INFO: UART1 Tx:gpio.0 Rx:gpio.4 RTS:NO_PIN Baud:115200]

[MSG:INFO: UART2 Tx:gpio.14 Rx:gpio.15 RTS:gpio.13 Baud:9600]

[MSG:INFO: I2SO BCK:gpio.22 WS:gpio.17 DATA:gpio.21]

[MSG:INFO: SPI SCK:gpio.18 MOSI:gpio.23 MISO:gpio.19]

[MSG:INFO: SD Card cs_pin:gpio.5 detect:NO_PIN freq:20000000]

[MSG:INFO: Stepping:I2S_static Pulse:4us Dsbl Delay:0us Dir Delay:1us Idle Delay:255ms]

[MSG:INFO: User Digital Output:0 on Pin:gpio.26]

[MSG:INFO: User Digital Output:2 on Pin:gpio.2]

[MSG:INFO: Axis count 3]

[MSG:INFO: Axis X (0.000,1220.000)]

[MSG:INFO: Motor0]

[MSG:INFO: tmc_2209 UART1 Addr:0 CS:NO_PIN Step:I2SO.2 Dir:I2SO.1 Disable:I2SO.0 R:0.110]

[MSG:INFO: X Neg Limit gpio.25]

[MSG:INFO: Axis Y (0.000,2440.000)]

[MSG:INFO: Motor0]

[MSG:INFO: tmc_2209 UART1 Addr:1 CS:NO_PIN Step:I2SO.5 Dir:I2SO.4 Disable:I2SO.7 R:0.110]

[MSG:INFO: Y Neg Limit gpio.33]

[MSG:INFO: Motor1]

[MSG:INFO: tmc_2209 UART1 Addr:3 CS:I2SO.14 Step:I2SO.13 Dir:I2SO.12 Disable:I2SO.15 R:0.110]

[MSG:INFO: Y2 Neg Limit gpio.35]

[MSG:INFO: Axis Z (-300.000,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: tmc_2209 UART1 Addr:2 CS:NO_PIN Step:I2SO.10 Dir:I2SO.9 Disable:I2SO.8 R:0.110]

[MSG:INFO: Z Pos Limit gpio.32]

[MSG:INFO: Motor1]

[MSG:INFO: tmc_2209 UART1 Addr:3 CS:I2SO.19 Step:I2SO.18 Dir:I2SO.17 Disable:I2SO.16 R:0.110]

[MSG:INFO: Z2 Pos Limit gpio.34]

[MSG:INFO: X Axis driver test passed]

[MSG:INFO: Y Axis driver test passed]

[MSG:INFO: Y2 Axis driver test passed]

[MSG:INFO: Z Axis driver test passed]

[MSG:INFO: Z2 Axis driver test passed]

[MSG:INFO: Kinematic system: Cartesian]

[MSG:INFO: Huanyang Spindle Tx:gpio.14 Rx:gpio.15 RTS:gpio.13 Baud:9600]

[MSG:INFO: Using spindle Huanyang]

[MSG:INFO: Mist coolant gpio.16]

[MSG:INFO: Probe Pin: gpio.36:low]

[MSG:INFO: Connecting to STA SSID:Jones]

[MSG:INFO: Connecting.]

[MSG:INFO: Huanyang PD0011, PD005 Freq range (120,400) Hz (7200,24000) RPM]

[MSG:INFO: Huanyang PD144 Rated RPM @ 50Hz:3000]

[MSG:INFO: Huanyang PD143 Poles:2]

[MSG:INFO: Huanyang PD014 Accel:5.000]

[MSG:INFO: Huanyang PD015 Decel:5.000]

[MSG:INFO: Connecting..]

[MSG:INFO: Connecting...]

[MSG:INFO: Connected - IP is 192.168.1.114]

[MSG:INFO: WiFi on]

[MSG:INFO: Start mDNS with hostname:http://LittleLR.local/]

[MSG:INFO: SSDP Started]

[MSG:INFO: HTTP started on port 80]

[MSG:INFO: Telnet started on port 23]

ok

Also this is the ESP32 from my smaller LR3, not the one that’s been having issues…

So maybe that LED and spindle ground?

$ss looks good.

Ouch, this is 4d6 psychological damage. ![]()

I’m not sure. The LEDs still did a few crazy blips here and there but only about 25% of what it did before. I need to put that other ESP32 back in and run it again to see for sure.

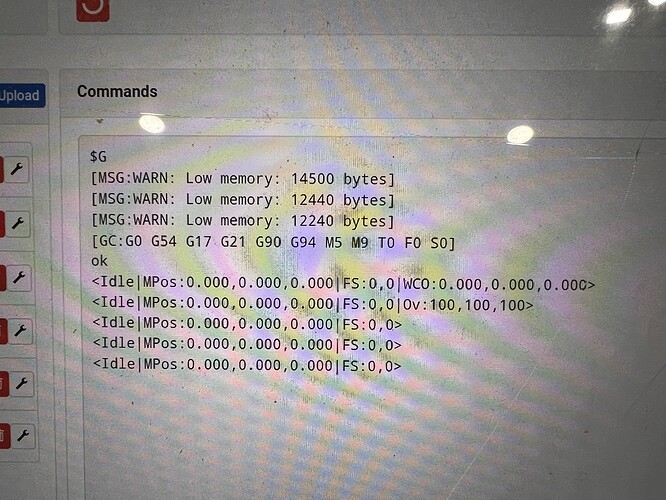

Ok I’m leaning towards a bad ESP32… Just ran a job with the original, job went fine. Went to jog to the next start spot and Y2 ran normal speed, Y1 half (guessing) speed. Rebooted and homed. Then it jogged fine to the spot, got ready and started the Gcode, it showed where I started it in the terminal then 2 low warning messages and that’s where it froze. I never had that issue when I had the other ESP32 in it with the exact same config file. I have these USB C ones I bought from you, thinking about throwing a resister on one of them and swapping it in and see what happens. @vicious1 your thoughts?

Edit to add…

This is directly after a reboot…

The USB-c need the pullup resistor for sure on any version before the v1.2 that just arrived.

Ok. I’ll look through and see what resistor is needed and if I have one. I do have some around just not sure what size off hand. For now it got what I needed cut tonight lol

3 cut 4 more to go

Found a 4.7K ohm resistor and soldered it on just to find out that the usb c board is narrower than the micro usb one and I didn’t want to bed it up to make it fit. So I grabbed the one out of the other machine again.

And it’s now confirmed it’s not the ESP32. Just had it mess up on the one from the other LR3 as well. So it’s got to be the RS485 board. That’s the only difference between this machine and the other one. And I know I’m not using the right wiring for it. So I’ll take that off until I get the shielded cat6 in later this week. Then we will see if that makes any difference lol

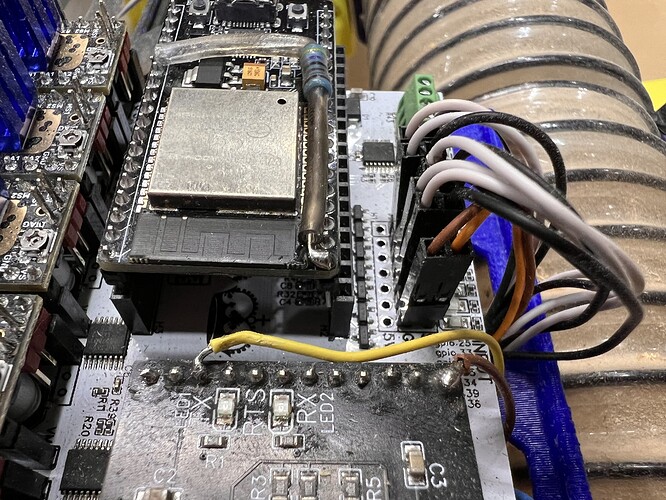

I’ve always been curious about this part of your build- why are spindle wires soldered to the expansion connector header instead of being landed in the RS-485 connector on the outputs of the expansion board?

Just to keep you guessing! LOL I’m just Joking.

Those aren’t the spindle wires. Those go to the second ESP32 for WLED. I needed 5v from the jackpot and that’s the easiest place to get it. On my other machine i just have dupont wires in those locations.

How far is the power run to the 2nd ESP32 you use for LEDs? That seems like it could.be.a source noise/resets/dropouts. Best practices would be to twist the wire pairs together tightly, and use some decent sized capacitors at both ends of that. Or use VMOT and have a DC-DC buck converter at the 2nd ESP32 if the run is very far.

Your motors going crazy seems like the steppers are beng reset, so even if the ESP32 isn’t resetting, maybe the 2209s are. If one resets at any time, it may default to different steps/mm and drive current than was loaded by FluidNC.

So your issues seem to me like one or more of the TMCs is gettng impcted by noise from either the spindle or the LEDs or both.

I have read that can be a problem with the wiring coming from the RS485 if its not shielded twisted pair. While I did use shielded cable its not twisted pair. And it runs underneath X Y1 and Z1. Y1 and Z1 are the steppers I’m having trouble with. I’m going to try changing the cable routing to get it away from those drivers and see if that makes a difference. And my shielded Cat6 should be here Wednesday so that should hopefully take care of it as well. I never thought about the power coming from there for the second ESP being an issue. It hasn’t caused any problems on my other machine. Its about a 2’ run from the jackpot to the second esp in the beam. And its not twisted at all. I will look at changing that to something better. I’m not using the 5v outputs but I wasn’t sure if they would supply enough for it. The others are being used to control presets on the ESP so cant pull from there. The other option would be take 24v from the main power in and then use a buck converter down to 5v for the ESP.

Maybe just pull that wire out of the box and run it out the logo port. Seems like that could be an easy thing to try. From there try not to route it tightly with other stepper wires that could pick up noise.

The other thing to look at here is your Vac hose. Did you run a grounding wire in it? a vac hose builds up more and more charge over time that could also explain why it takes so long to happen.

Random issues are not easy to find.

I have the lid off of the box for now since we were concerned about the drivers getting warm so I just ran it right over the side. Straight from there it leaves the CNC so its not around any other stepper wires or anything now.

The 2 1/2" hose I am using has a wire all the way around it that is grounded, Do I still need to run another wire inside it??

I agree completely, and I also know I can be hard headed about changes I don’t want LOL. Thanks for coming along for the ride!!!

I don’t think so but maybe…I wonder if that is considered insulated since it is inside the plastic. Can you feel a charge on the outside while it is running? Dang, I really am not sure, seems like it should be able to find the path to ground since the plastic is charging up…but then again the wire is insulated. We need some EE’s to help!?

LOL maybe ill just run one inside just to be sure. Cant hurt. I don’t feel a charge on it at all but I also never did. It wasn’t grounded at all when I was running the SKR. I was just out there running it and was wondering if I should tie a ground wire to these bit aluminum struts. Wondering if they could be picking up anything as well???

I don’t really want to start a great dust collection debate…

But I did look into this quite a bit at one point, and I don’t believe you gain anything by attempting to ground PVC, which is an insulator.

If your flex hose is PVC, it’s unlikely that it can build up a very big static charge, and from what I previously gathered, grounding the inside of it will only help very near to where the wire touches the PVC, if at all.

Most of my research on the matter was to do with static discharge in dust collection causing fire since there is a large group of people who will swear your house will burn down if you don’t ground your PVC.

However, I do not have the slightest clue about whether or not it could build up enough charge to cause interference. I would guess, though, that the charge can not make it through the PVC to the wire that is inside.