Hello everyone, I wonder if anyone has had a similar issue? I have just replaced my SKR Pro 1.2 with a jackpot, everything worked perfectly before the change. I have the correct configuration, I am 100% sure I have connected it correctly, and I’m receiving signals from all endstops. The symptoms I have are as follows: The X, Y1, and Z2 axes work as they should. However, the Y2 axis lacks power to the motor. The Z1 axis has power to the motor but doesn’t perform a pull-off when it reaches the endstop. I have tried moving Y2 from output (A) to output (C) and copied Y2 instructions in the config file to output (C), which gives me full functionality. I have also tried changing drivers to rule out any issues with them, but there is no difference. I have cleared the ESP and started over, reloaded the config but the exact same issue persists. I’ve ordered a new board from Ryan, but it will take a few weeks to arrive to north Sweden. If I can resolve this issue with the current board, I’ll use the new one for the next build.

@vicious1 I’m sure you will want to see this one

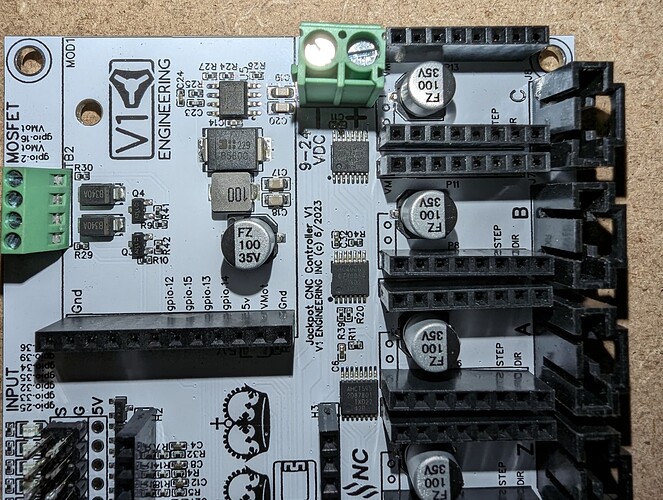

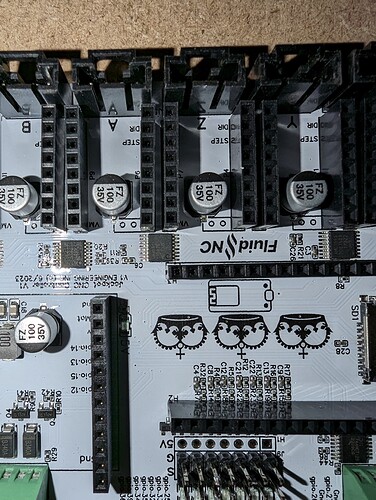

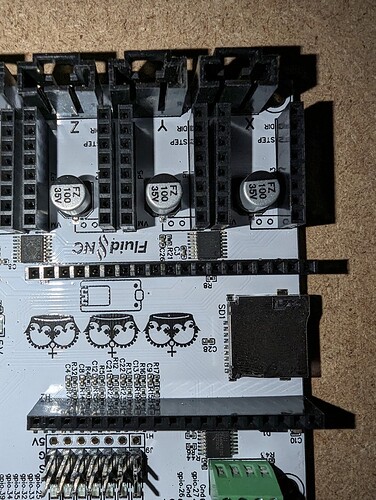

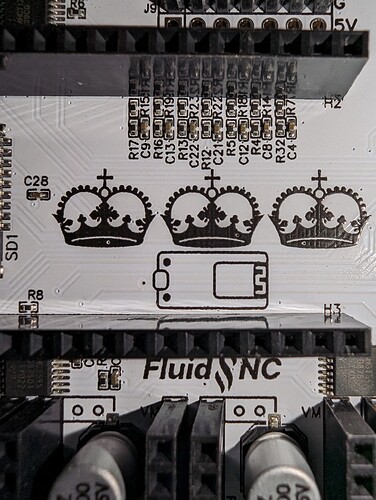

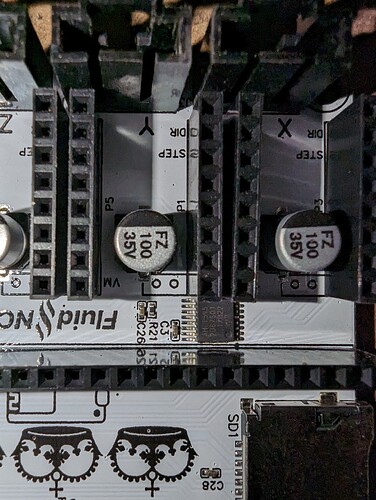

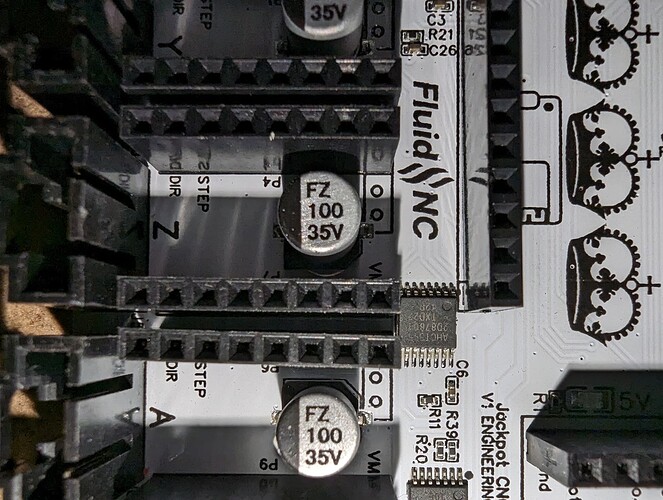

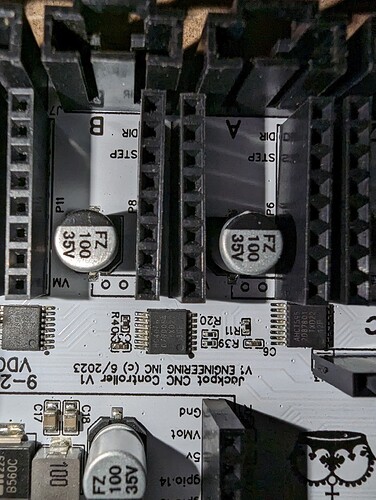

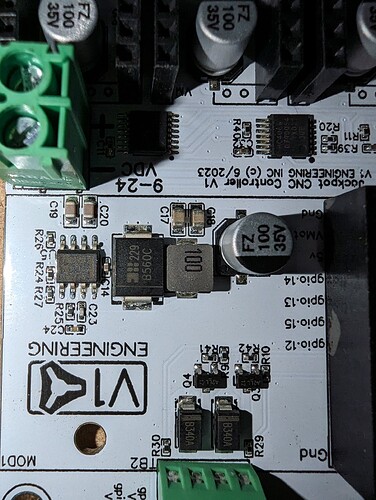

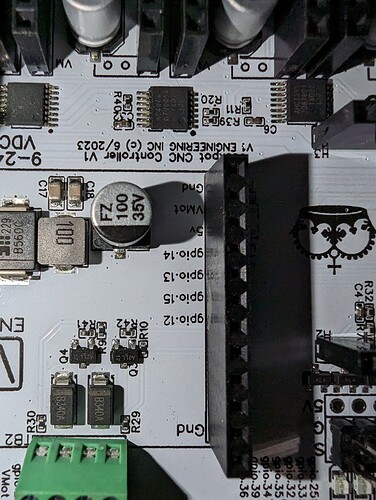

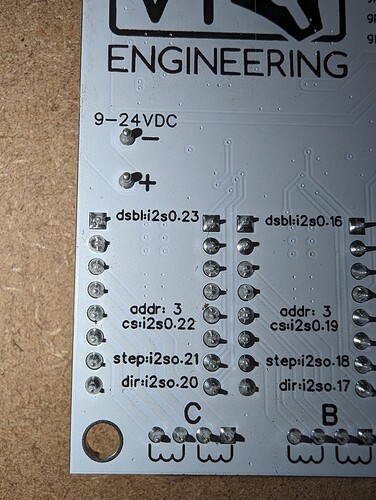

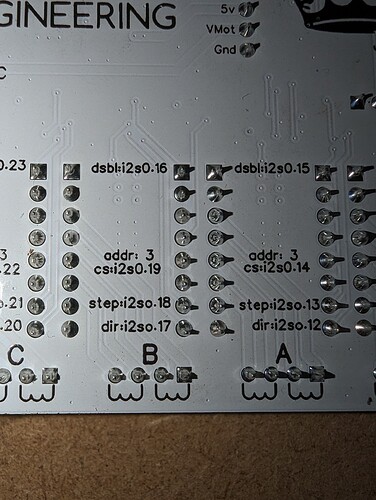

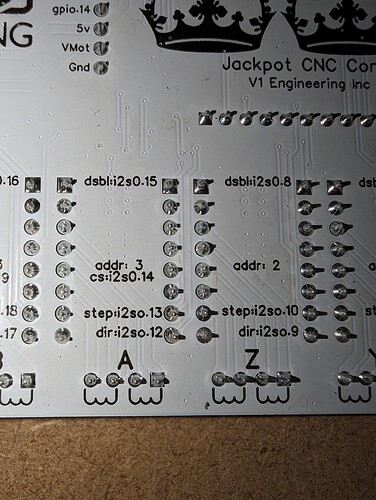

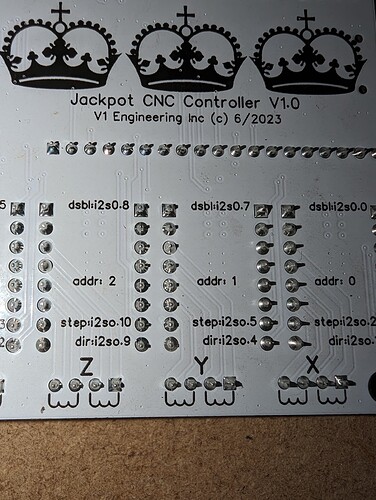

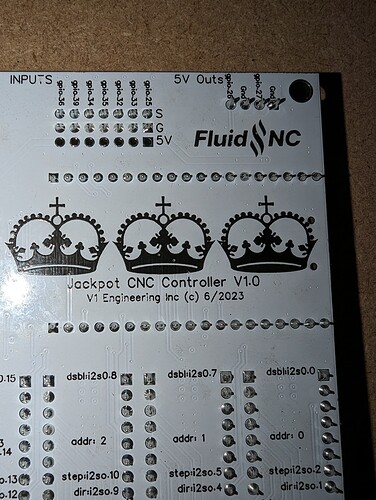

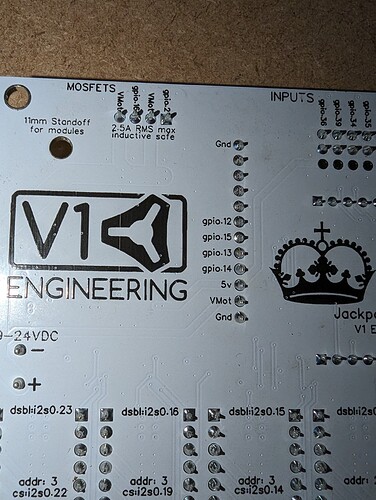

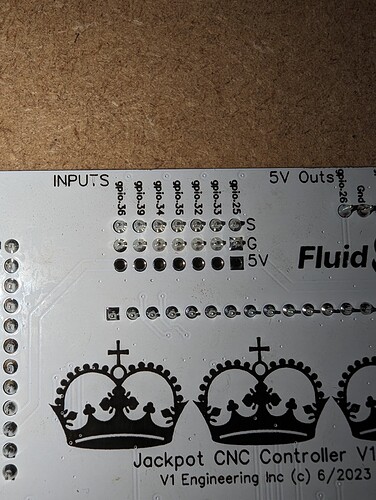

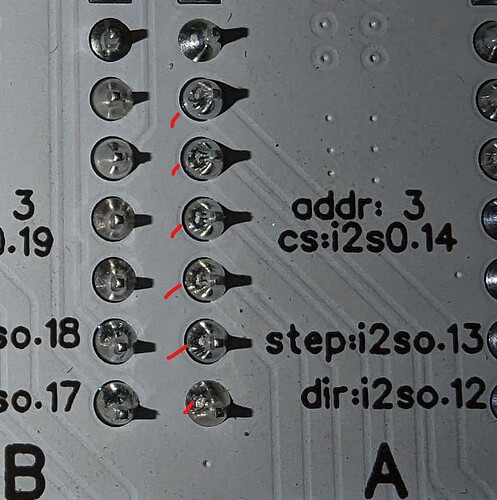

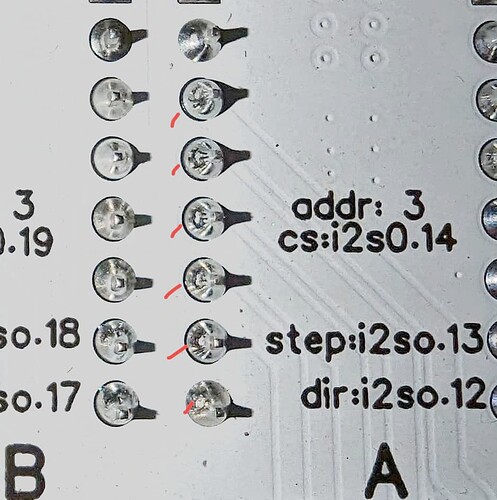

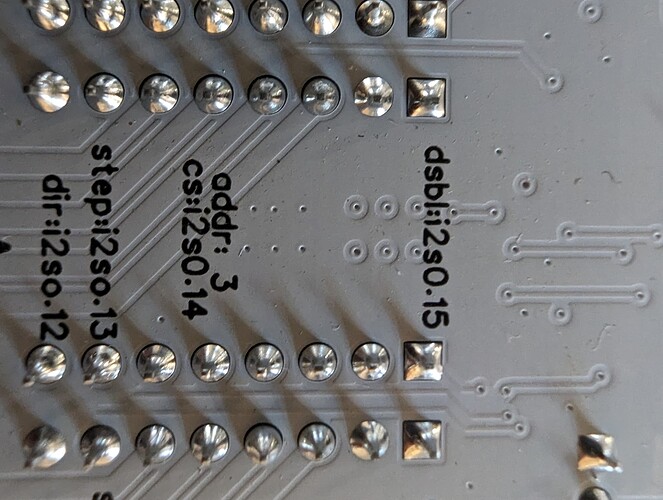

Can you send some clear high resolution pictures of your board, top and bottom so I can look for solder bridges.

Meaning nothing happens at all, does it lock up at boot?

Without homing does it move back and forth? This could be a endstop issue. The only way both are related could be a solder bridge on the CS chip maybe…

Are you using the 3.7.8 firmware with my newest configs? (chrome browser, FluidNC Web Installer)

I will take some pic and send it to you.

Y2 dont lock up at boot no reaktion

Z1 moves back and forth whitout homing.

If I activate the endstop before it reaches the home position, the motor stops. But dont do the pull off

I have tried both 3.78 and 3.79, no difference.

They have to both trigger before it pulls off simultaneously.

Yes i use the chrome browser, FluidNC Web Installer

Okay, lets try another option, the pics look okay.

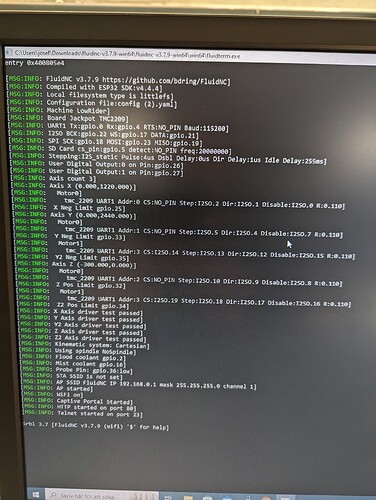

If you unzip this in the win64 there is a fluidterm program (Releases · bdring/FluidNC · GitHub). Can you run that and reset(ctrl r). Put up or screen shot the entire readout. The board does a diagnostic at boot.

ok i will try it tomorrow. thanks for quick answers. much appreciated

Sure looks like a crap solder to my untrained eye. But it also appears to be making a connection on the other side so I don’t think that would be enough to cause any actual problems.

I haven’t noted it will check it

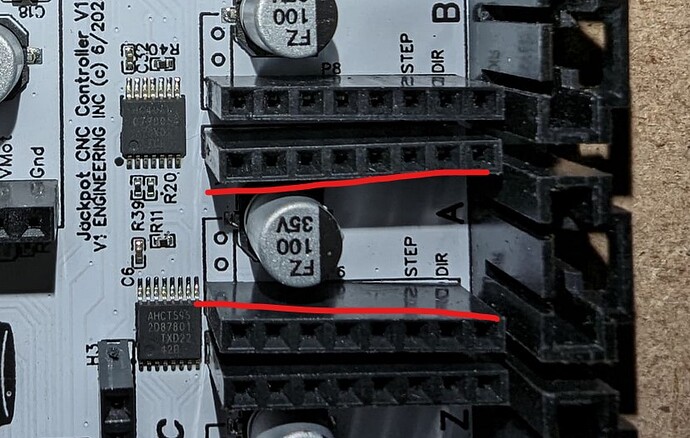

That’s also the stepper with the weirdly sloping headers, and the one misbehaving- right?

Using an overlay to brighten by converting a copied layer to greyscale, decreasing luminosity and adding contrast, and then inverting that- it still looks really crappy to me.

I’d like to see a better picture at a different angle of the A stepper header solder work.

Are you 100% sure that a wire didn’t come loose in the dupont connector going to the board? Faulty wiring could cause the same issues you are having. Ive seen pins push out of the dupont connector before and be barely noticeable when you are looking for them. Yes… Speaking from experience LOL

The FluidNC boot looks clean to me at least for that one boot. if you reset it a few times, does it spit out errors occasionally?

The solder work still looks suspect to me in that latest photo.

When I see things like crooked connectors or possibly cold/bad solder workmanship, the whole hand assembly work for the board becomes suspect to me.

This is a strong indication that the problem is specific to the Y2 (Axis A) location, and that it probably isn’t the 2209/UART as if it was, we’d see an error on boot. You swapped drivers already so I dont think it is a bad 2209. Another reason to try a few more boots to look for any errors.

Very possible, but at least for Y2 seemingly ruled out by moving Y2 to the C position. It’s worth inspecting the stepper connector and endstop contacts closely.

This could be the issue you’re having with Z. One of the endstops or wiring has an issue, or perhaps another suspect solder joint. Issue with Z could be the Z endstops are mismatched betwen motors?

This also clears the Vin pin right? So that leaves Vmot and the outputs. It can’t be all 4 outputs if even two worked there would be some sort of resistance at the stepper, right? Even if the big cap had an issue it would still be fine since the Vmot is still connected dirctly to power.

Hmmm

when Z and Z1 go to home position, Z only stops while Z1 does a pull off, if I switch places on these motors and end stops, I get function on the Z motor. I have switched drivers and there is no difference. therefore I don’t think I have a problem with either cables or connectors.