Please don’t reality check my delusions of long term laziness being the way. REAL reflection can be painful, but helpful in avoiding insane repetition of failed approaches ![]()

They might have been $11 when you bought them but they were a lot more than that just before they went unobtainable from your link on Amazon…

Something to do with delivery country then?

It was a lot more than €13 before it went unavailable for me.

Amazon is definitely different for different countries.

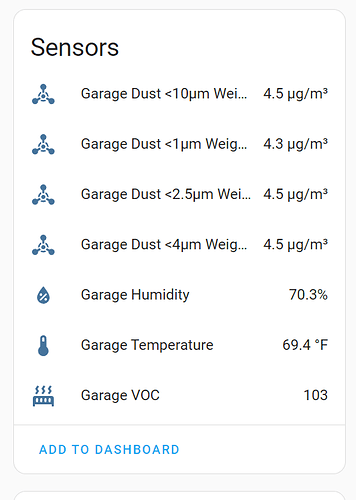

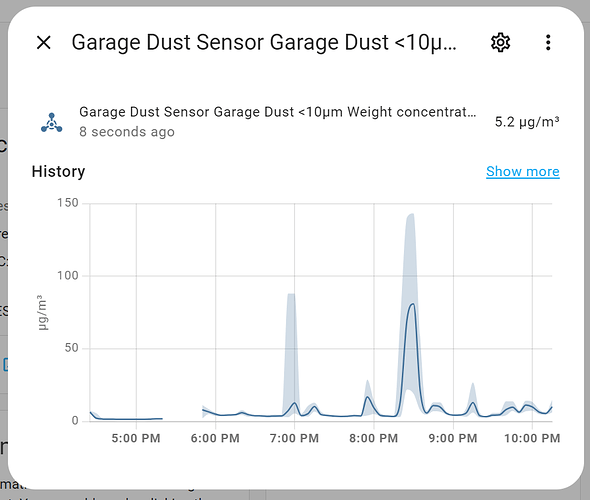

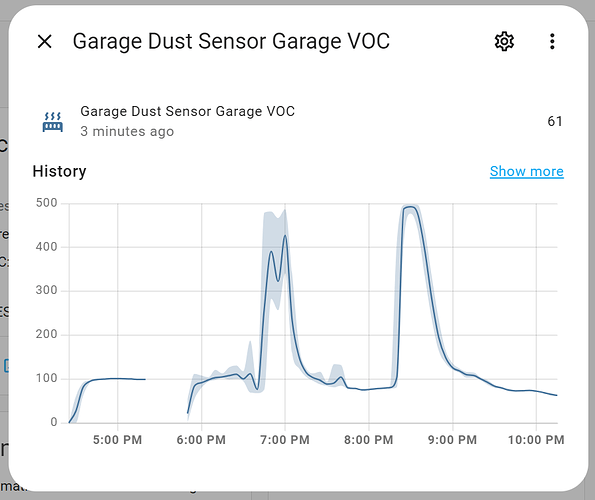

Added a particle sensor to the Dust filter this afternoon. Now as soon as I learn what is good and whats not I can use the values to turn the dust filter on and off as needed. So far we usually remember to turn it on when we start things but when your busy trying to get stuff done it can easily be forgotten as well.

Ask a doctor everything is bad

Ask a old woodworker they’ll yell profanities in your face

The answer? somewhere in the middle… ![]()

![]()

Just spent a few hours out there working. Ran the LR3, Sanding, and even sprayed some rattle can Poly. Sensor seems to be doing good and I guess the filter is doing good as well. Seems like it goes back down pretty fast…

The 2 real high peeks seem to line up with when I was spraying the poly…

I’m just going to let it run for a while and collect some data from it. Then Ill make a decision on how to use the info in an automation for the dust filter.

I have an old kitchen hood, which has filters in it. Do you think I could use it as a dust collection? ![]()

It’s supposed to filter smells etc in the kitchen originally.

If this sensor is in your garage, maybe you should get an exhaust fan to turn on when values are high.

Which particulate sensor are you using?

It is mounted to the bottom of my DIY Dust Filter

Sensor is a SEN55

I would think about mounting it to opposite side of shop. The air next to the filter will “clean” much faster than the opposing side

Not a bad idea at all. With the way I ended up mounting this one I may just end up adding a second one. The way my shop is set up its basically 2 rooms made into one. The original 2 car garage built on the house in 1967 then somewhere in the 90s they added a 2nd 2 car garage on to the end of the original. So you still have the garage door opening that leads into the “new” part just no door there. The ceiling in the “old” section is 11’ where the “new” section is only 8’, then the 7’ tall opening which was the original door. I’m not sure how much effect the dust filter being on the high ceiling will have in the newer section but a second sensor in that area would tell me that I’m sure.

My thinking is to mount the sensor closest to where I spend most of my time doing work. In the case of my shop, it’d be the middle of the shop about 1/3rd from the back wall where the big work bench sits.

Every automation has a toggle to enable or disable it. Are you sure this isn’t just checking the state of that toggle?

I’m honestly not sure. All I know is adding that condition stopped the dust collection from turning off when I turn it on manually. And it still works when the spindle turns on and off.

Here is the yaml from the automation if that tells you anything more…

alias: Dust Collection Off with Spindle

description: ""

trigger:

- platform: numeric_state

entity_id:

- sensor.esphome_web_2a1f41_spindle_current_sensor

below: 0.13

condition:

- condition: state

entity_id: automation.dust_collection_button_on

state: "on"

action:

- service: switch.turn_off

data: {}

target:

entity_id: switch.air_compressor_moisture_drain_dust_collection

mode: single

I have been heading down the Home Assistant controlled dust collection route as well. It was fun to see this conversation on my every 6 month visit to V1.

I am turn on/off my 2hp dust collector with an Electromatic relay controlled by zooz relay. It is triggered by zooz heavy duty power switch doing power monitoring on my 120v tools and an Aeotec Heavy Duty Smart switch monitoring my 240v tools.

My next step is hard piping and blast gates.

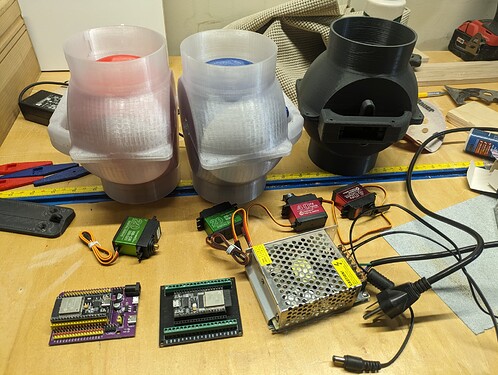

I was going to just put an ESP32 controller on each one running ESPhome, but now I am hoping I can just control all 3 (maybe 4) with one ESP controller and extending the servo wiring.

Any recommendations on what wire to extend the PWM control over 20-30 feet?

PWM is pretty robust to noise and line attenuation because it just has to cross 2.5V. With a servo, it will probably be fine. A shielded twisted pair would be better. If you really get desperate, you can use a line level converter as an extender. Even wiring both sides with 5V will recreate a strong signal on the other end. But I doubt 30ft will have a problem.

As a point of reference, I have 50’ runs for addressable LEDs. And they are way more picky than a servo.

Would cat 6 and using the pairs be a good fit, or do I need a thicker gauge?

Mmmm… As the idiot who is spearheading the cloudification of our products, I may pick your brain at some point. Moving from hand-crafted EC2 instances to semi-automated stacks of Fargate services to support Enterprise scale SaaS is… interesting. Especially while trying to learn about AWS from AWS docs and StackOverflow.