Continuing the discussion from Z Endstops Ignored - Megatronics 3.0 - Homing Dual Endstop LowRider2:

It has been a while since my last post due to some unfortunate events. Sadly, I haven’t had the opportunity to use my CNC machine, apart from the initial tests I conducted in January 2021. As a heads up my brain is still adjusting from 3D printer logic.

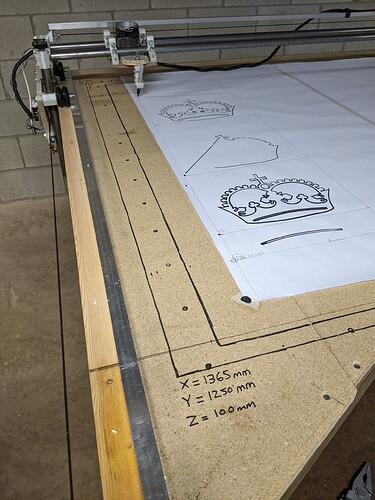

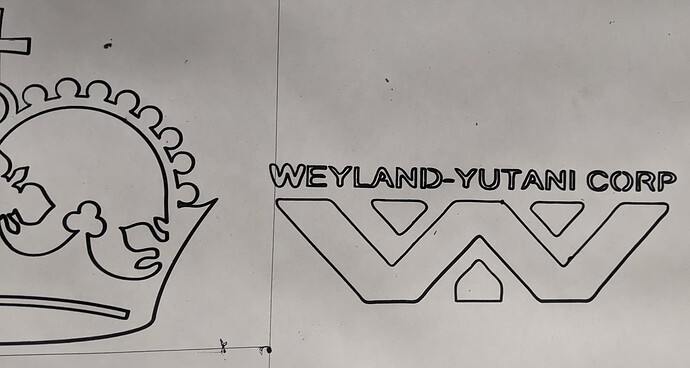

Recently, I decided to bring my machine out of hibernation and began with a crown test. However, I encountered an issue with the machine not seeming to recognize the origin points I set using G92 compared to the origin set in ESTLCAM. I recall experiencing a similar problem when drawing crowns after completing the build.

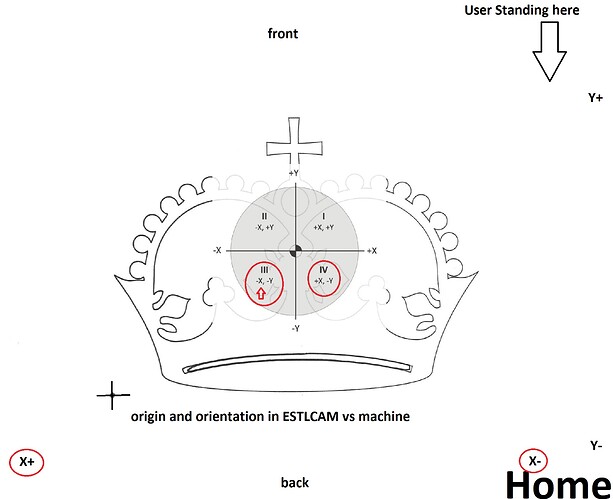

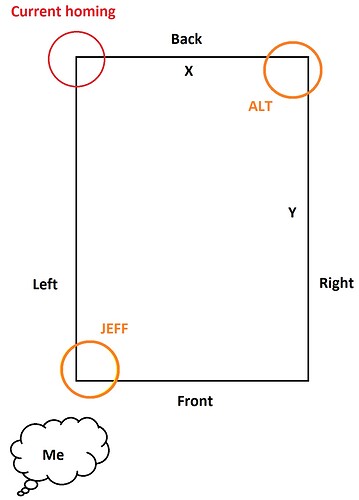

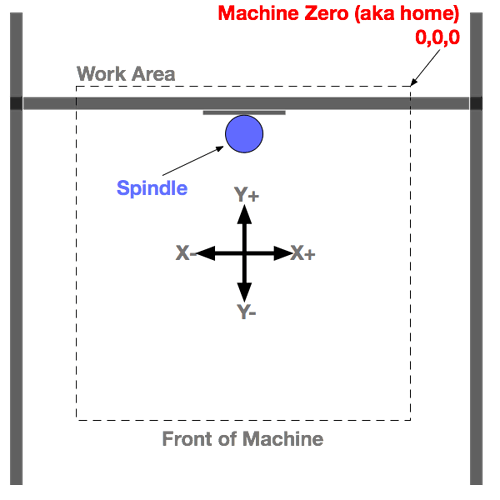

When standing in front of the machine on the side that homes, I can confirm that my machine squares itself at 0,0,0 in the back left corner (as mentioned in my previous post). For the crown test, I placed the file in ESTLCAM and set the origin to the bottom left of the crown (default position). I am using Pronterface on a Linux PC to send the gcode to the control board; I’m not using an LCD screen.

To prepare for plotting the gcode, I followed this procedure:

Home All (to square the machine)

Zero X and Y to the intended origin of the workpiece area using G92

Conduct a test movement (G1) to confirm the positioning

Zero Z using G92

Move Z up

Conduct a test movement (G1) to confirm the new G92 origin positioning

Make necessary adjustments and run the code.

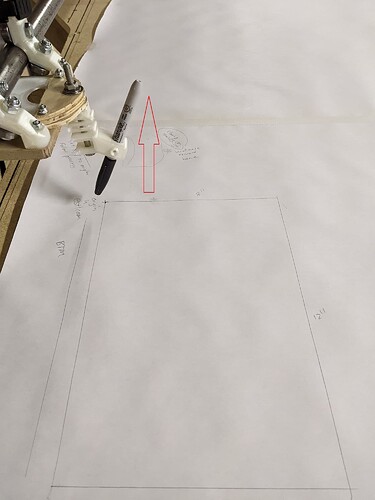

However, when I execute these steps, the pen moves away from the manually set origin on the X-axis and goes to an ‘unknown’ origin point in the X+ direction (indicated by the red arrow in the picture / to the right side of my machine from operator’s perspective). I assume it’s moving to the origin set in ESTLCAM and then begins attempting to draw in an area that is not on the workpiece; to avoid dramas I’ve been setting Z 5mm above the bed for testing. For all intensive purposes it’s behaving as if it has three reference points: home, G92 manually set origin, and the one in ESTLCAM that’s failing to match the one set by G92.

The crown is drawn in the correct orientation, with the bottom facing the back of the machine and the cross towards the front of the work area.

I attempted to manually move the machine back towards the home position after setting the origin with G92, but it triggered a clamping error (I have clamping enabled to prevent axis crashes, should that be disabled?).

Thoughts:

Could it be that I am homing the X-axis in the wrong direction, similar to the issue discussed in this thread? (https://forum.v1e.com/t/mpcnc-primo-orientation-endstops-and-mirrored-project/31461)

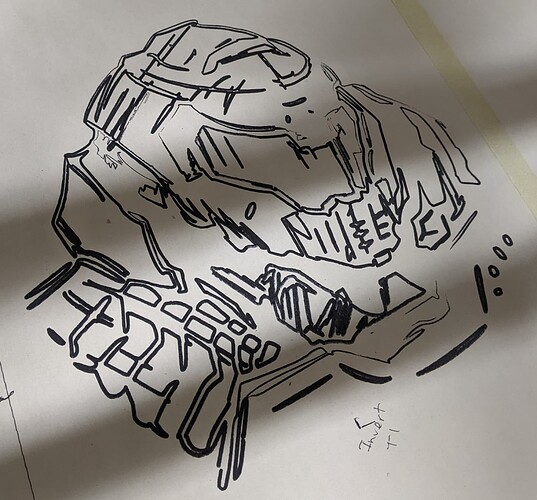

I superimposed the drawing from the aforementioned thread on top of the crown test and matched it with the orientation of my machine and ESTLCAM. This suggests that I need to home the X-axis to the other side of the machine requiring me to move my endstop switch and re-flash the firmware, right? Seems like I may have screwed up ![]() ?

?

I intended to set the G92 origin at the same place as the origin in ESTLCAM. I looked into possibilities that I screwed up a setting in ESTLCAM and found the following: (https://www.estlcam.de/e2_nullpunkt.php) “…Tip: some CNC controllers always shift the origin e.g. to the left, lower edge no matter what you specify in Estlcam. However most controllers also have an option do disable this behaviour.”

Is it possible that I made a mistake in ESTLCAM, firmware, or the issue specific to using a Megatronics Control Board?

I know Pronteface is is generally used for 3D printing, should I abandon it for Repetier?

Has anyone encountered this issue and or can confirm my thinking above?

All the Best,

Josh