Hi All. I built a MPCNC Primo earlier this year, and it’s been working superbly for most of that time. Occasionally, one of the motors (X2 I suspect) suddenly has a short outage, which usually disrupts anything I was trying to mill.

The MPCNC was built with stainless steel rods for 600×600×150 mm workspace, SKR Pro 1.2, 2209 Drivers, TFT35 E3 V3 and dual end stops. Parts were printed by me.

I crimped the connectors myself using JST XH connectors, so it’s not a loose connector issue. I have attached pictures of a test milling to show the problem.

Images

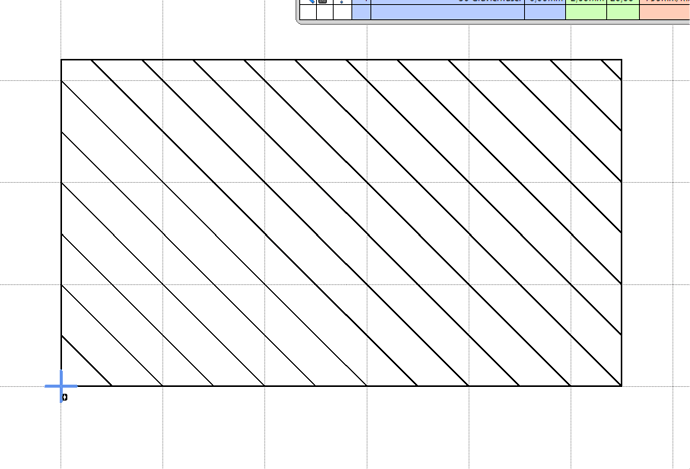

What is supposed to be milled (ignore the border):

Unable to add a picture since I’m a new user ;), see below.

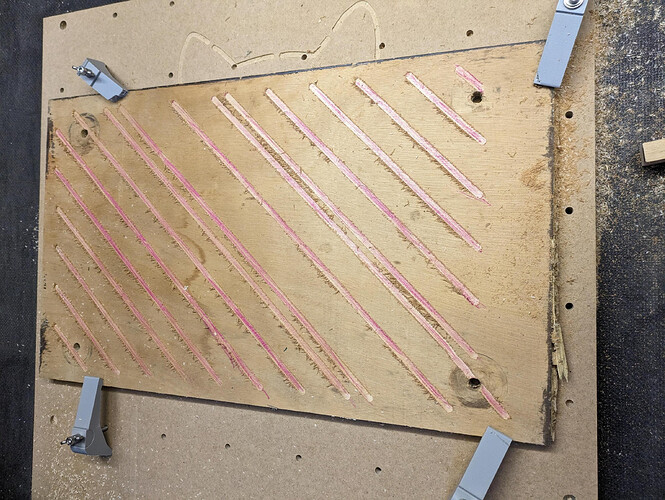

What is milled:

You can see that the lines are supposed to be the same distance from each other, but they aren’t. In the lower right corner, the end of a line has a notable nudge to the right. The nudge was the first issue, and since the lines weren’t milled left-to-right, the misalignment is visible all across the board.

Something I noticed while troubleshooting is that when homing, the X2 truck arrives slightly later than the X1 truck (which would be fixed after homing). However, once I moved the axes and tried to home again, there was still a noticeable delay for the x-axis, whereas there wasn’t any for the y-axis. I checked the distance of the stop blocks multiple times, and they are the same distance from the corners.

Any insights or suggestions would be greatly appreciated.

Regards,

Rockfish

This is how it should look.

Image

I would say there is a 90% there is some sort of bad connection, crimp, or otherwise. I leave that 10% open just because we don’t know what hardware or electronics you have, did you buy it from V1 or self source? If you self sourced lets see a picture of what you have.

There are only a few possibuilities here.

- CAM is bad, and the machine is asked to do something it can’t and skips a step, travel too fast or cut too fast. Travel too fast is the most common.

- Bad connection somewhere. Very short intermittent outage kinda seems like a skipped step but is not.

- loose grub screw / broken belt. This will have a predictable “skipped step” Seems random until; you find it then you can make it happen.

- Set your electronics wrong and the drivers are doing a thermal shutdown. This lasts many seconds, not the case here.

- Hose or wire getting snagged somewhere / mechanical obstruction.

The picture helps but in what order were those lines cut in the wood, that would help narrow down what is happening.

Hi Ryan, thanks for the detailed reply.

Today I was testing around a bit and by sheer coincidence I saw a little screw fall from the X2 truck. I had found the culprit. It was, as you suspected, a loose grub screw. It seems I hadn’t tightened them enough and one had worked its way loose.

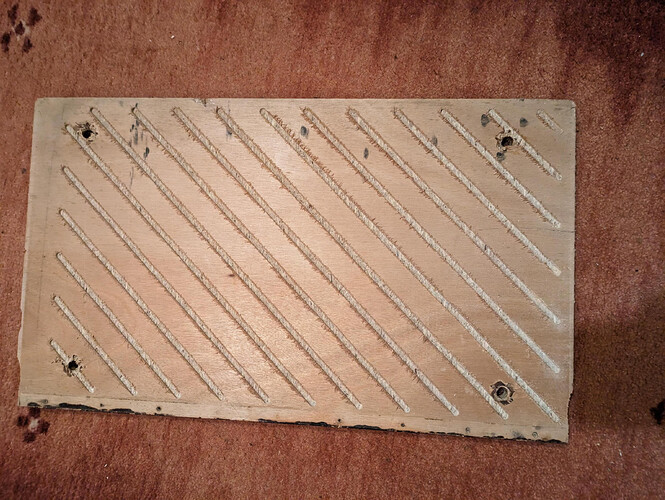

After fixing the loose screws, the test now looks as follows; all in order.

Image

Thanks for the help and regards,

Rockfish

1 Like

Well, that makes you a bona fide part of the Crew now…dam grub screws has gotten us all. LR2 almost got scrapped because of a loose grub screw. I think I started taking it apart to throw it away when I found it.

2 Likes