Hello all. I recently bought a bigger laser for my mpcnc with a rambo 1.3 board. I’m using power from the board and have the black wire on pin 45 and my ground wire on a grounding pin. In lightburn, whenever I try to fire the laser I get no laser and a red light on LED3. This only happens when using M106/M107 laser controls. The laser doesn’t fire on M03/M05 or inline but I don’t get the same red LED3 on either setting. Any advice would be appreciated as I haven’t changed any software and simply went to a new laser.

Is the new laser more powerful? Is it drawing too much current on the board. I needed to put a separate power supply on the laser to use it with my older controller board.

The controller just supplies the PWM signal and a shared ground wire, the 12V comes from the power supply with, also, a shared ground wire.

To provide a little more assistance, it would be nice to know the laser you’re running, and the version of software on your controller.

Mike

[This is the laser I’m using]

(https://a.co/d/c5jUZjD)

I had it working last week but over the weekend when I went to turn the machine on, I noticed the fan on the laser was much quieter like the board is sending less power to the laser by default.

I’ve tried several combos of where to put my signal and ground wires in the 3x4 set of pins on the board. I had to pull the included plug off the laser and I didn’t put new plastic covers on the pins before plugging them into the board. Is there a chance I jumped two pins and have made the laser or board unhappy?

The spec on the board description is a little confusioning: on the one hand it says 80W and on the other product listing it says 10W. Devide the wattagw by the volts and the current in the 80W case is over 7 Amps.

I’m not sure if the RamBo is able to provide that with any of the 12 volt pins except the Bed Heater, or maybe the extruder heater block. The Rambo has a couple fuses on the board, have you checked to see if they have been blown?

I’m just a little hesitant to pull too much current through the board. I think it would be safer to use a separate 12 supply with the wiring arrangement I described above.

Mike

If you want to use the Rambo power supply, connect the laser at the Rambo power input point. That way you don’t pull any power through the Rambo board at all. Of course, you must have a power supply that provides enough power for your MPCNC and your laser.

Many of the laser setups I see on the forum use a separate power supply. I use a separate power supply for my laser. The only (minor) issue, is that the two power supplies must share a ground. Since only a tiny amount of current is used for the PWM pin, the ground wire can be small and connect to any ground pin on the Rambo board.

You mention using M106/M107 to control your laser. Unless you’ve made changes, M106/M107 control 12V fan pins. Issues with fan pins: 1) they are ground-side switching, which only works for a minority of laser modules, 2) some laser modules will not work with a 12V PWM signal, and 3) fan pins should not work at all unless you use a separate power supply. You can reassign the fan pins to a 5V PWM pin, but this does require you to compile and flash new firmware.

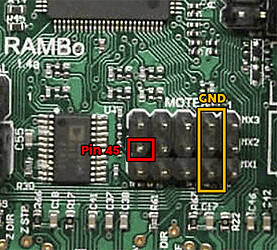

If you are using a recent version of the V1 maintained Marlin firmware for the Rambo board, laser features are enabled. The laser PWM wire should be connected to pin 45:

Pin 45 will work with M03/M05, but you will get significantly better quality in your engraving and cutting if you use inline commands. To use them, your tool must generate inline commands, and you need to place the following at the top of your g-code file:

M3 I

Almost all authoring tools have a way to add this command automatically.

Note that the current V1 maintained version of Marlin has issues with the LCD laser menu items. It will be fixed the next time V1 updates the firmware. In the meantime, you can turn pin 45 on and off (for testing) using M42.

As for the laser wattage, you can completely ignore the 80W number. They use really tortured logic to get that number, and it is meaningless. It cannot even be used for input power required. The 10W may be accurate. The price you paid for the laser is about what I would expect for a 10W optical (single diode/old style) laser, but manufacturers lie about output/optical power as well.

I have been messing with this laser off and on all week and have done a couple things to no avail.

Re-flashed firmware

Rewired the whole board to check all connections

Tried using the pin directly right of pin 45 and finally got somewhere.

The pin directly right of 45 finally gives me laser control, but the laser is constantly set to 100% power. Pin 45 now increases fan speed on the laser, but doesn’t actually turn the laser on. I’m not getting the ominous red light anymore, but I still have no pin45 laser control seemingly from nothing changing.

I do have the power for the laser stuffed in the connector providing power for the board. I’m just using pin45 to tell the laser when to be on, and at what power to be on. At this point, I’m about to just send it and try engraving a cup at 100% power to see if I can make it work.

First, if pin46 is working, you can reassign laser control to pin46. The pin is defined in Marlin/src/pins/Ranbo/Rambo.h in this line:

#define SPINDLE_LASER_PWM_PIN 45 // Hardware PWM

If your laser is on full power, it is possible the PWM logic is inverted. I’ve never played with it, but I noticed this line in configuration_adv.h:

#define SPINDLE_LASER_PWM_INVERT false // Set to "true" if the speed/power goes up when you want it to go slower

You might also consider taking a step back and checking pin45 with a multimeter. Carefully connect your multimeter to pin45 and ground, then start up the control board and check the voltage when you send an M42. Also, what is the exact command you are using for your M42 attempts (assuming you are trying M42).