Maybe a torque spec…? All hardware uniformly tightened. Wow. Almost typed that without laughing.

All kidding aside, following along this thread, I’m impressed it was as close as it was. Nice job with the new design!

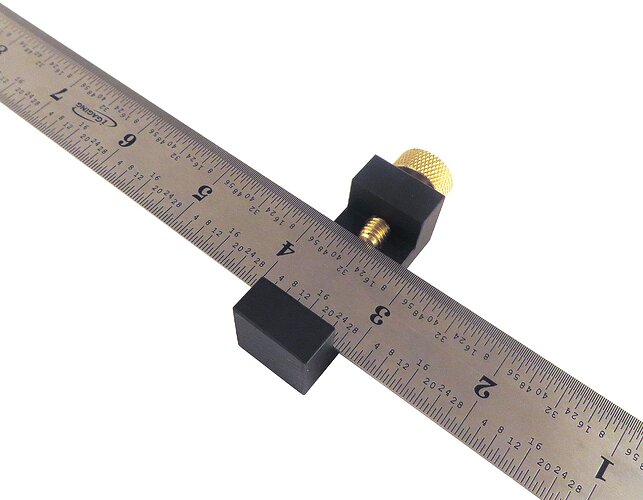

Track saws are an option for long rips. I use a ruler with length stops to quickly repeat accurate setting of the track on both ends of the rip, but you need long, straight tracks. Some multiple-piece tracks don’t assemble straight without some effort.

The track saw is easier to handle than trying to manipulate large sheet stock on the table saw.

Question, would putting plugs in the end of the EMT and screwing the ends of the EMT into the perpendicular plates stabilize the gantry ? The side plates would need to be a little larger.

I have not noticed any deficiencies there. With the right type of inserts, that could make for a very solid connection. I do think in most cases that would need very accurate tubing cuts, and that can be hard to do.

Tracks saws and saw guides would work. A table saw really wins for accuracy here though. An overlapping Y piece could work, the longer the overlap the more accurate the joint. Then it just comes down to if you have a table saw build a traditional torsion box, if not slap together your LR on a flat-ish sheet and cut out the design I want to make.

Or mount a long arm to the core that sticks out the front (points in -Y direction).

Then as X sweeps left to right see if the distance from the end of the arm to the table changes. Then you are measuring not just twist in the rails but also if distance between the rails induces a tilt of the core.

If you surface the table and make the arm as long as Y you’ll be able to measure crazy small amounts of differential tilt.

I also have some hand drawn plans for a torsion box table with a CNC, but Schneewittchen was just too small. The idea was to have segments you can puzzle together either with latches or with interlocking pieces and strong magnets (I do love magnets… :D). Never left the drawing stage though, I only cut the holes for the vacuum table with the CNC. ![]()

This is the table where my idea came from: https://buildyourcnc.com/ModularTorsionBoxTable.aspx But obviously segments. ![]()

Ohhhhh, great idea. Slap the longest square I have on the face of the core and sweep back and forth…Nice.

Cool! I was thinking something along those lines with a little more LR3 specific flavor!

Fusion is crashing like crazy on me today. I am going to try another computer and if it still keeps crashing I’ll give it some more time.

Didn’t you learn in high school or uni that tramming is not an effective learning method? Consistent review and discussion with a peer learning group is much better than tramming before exams…

Wait… wrong forum…

Can we have ![]() as a reaction for KVCs posts?

as a reaction for KVCs posts? ![]()

Three years ago you were like “Endstops are not really needed!!”. ![]() Now this.

Now this. ![]()

Yup taking a hard left turn. IF people really want to start chasing zero’s I am not going to shoot them down. If you have noticed, instead of me fighting that lately, I help push them further and the conversations typically end up with them saying “that is enough for my needs”!? If you take out the measurements and bring in real world demo’s of measurements, it seems to really help drive the point home.

Who knew, it’s as if internet people just want to resist no matter what the outcome.

Never surfaced a spoil board in all these years of CNCing. I shaved down a once obvious high spot but it’s a new me. I am adding a chasing zeros, or advanced tuning page to my to-do list.

I think it’s a good idea to encourage that. Even though your machines are entry level machines if you look at the price point, you make sure that they can compete with high-lvl machines if you want to.

I think that a lot of my “problems” are only there because I measured. My first inlays weren’t perfect, I needed to make sure that it was square manually, pushin it against stop blocks, so now I also want endstops, I had to surface the spoil board for my primo because my table was shitty, there were only slight ridges that never bothered me until I did the cutting board. When building the vacuum table it became more than obvious that the table was really crooked when I had to surface the MDF from both sides to let the air flow through, so I told me I needed an absolutely flat table for the LR3.

Surfacing gave me ridges, I trammed it. There is a slight lifting: I need to get that out. There are still ridges on the left side but not in the middle: could the screws still be to tight? It still moves around 5mm back even after twisting the gantry. Maybe it is my strut plates that didn’t cut through completely, maybe I didn’t clean the holes enough and now they are pressing the gantry back (I am going to check that today).

There was no need to do something about most of these problems, after twisting the gantry there is maybe 0.2mm lifting, one of the braces rubs very, very lightly because I had to tighten the core a lot (and I still think it’s the 25mm’s fault, without having evidence).

What I want to say with this: my cuts would still have been good enough to never see any of those issues, my control box, cut with the LR3 is fine, as is the grid of the new vacuum table I cut way too fast and deep just to see whether I could and I am pretty sure nobody would see the problems but me and a very, very trained eye… But somehow your expectancy grows, you want it to be perfect. I have good ears (I used to hear the beeping of those old TVs when it was turned off three rooms over and my family though it was impossible), I hear every tingling sound a bearing makes and it annoys the hell out of me, so at least those have to be spot on. ![]() I am nearly at a place where I am satisfied with the LR3, and I guess most of the problems are my own doing.

I am nearly at a place where I am satisfied with the LR3, and I guess most of the problems are my own doing. ![]()

I just do not want to push it like it is actually needed. 95% of the time, people will never know if they are way out of tram and pretty far out of square.

Same reason I never want to have a fancy table. I do not want people to see that and think they need to build a fancy table. All the CNC’s work great screwed down to any 1/2" or thicker surface.

Can it do all the fancy stuff, yes, after your first new build, no. Absolutely not, you need to tune any machine you buy to get finer and finer results. I went through most my life never adjusting a table saw fence or my chop saw backstop, heck I made most my stuff with a jigsaw for probably half my life. I do not want someone build the machine and spend weeks on end chasing zeros to maybe possible get them then go to make the first cut and try to cut a square at 100mm/s and tear apart the machine,…just to have to do all the tuning again.

What people NEED, is very hard to determine. If I say it can do 0.01mm it has to be able to do that. So I choose to always ask what people expect, or need for their types of projects. If I lose customers because I do not have misleading specs, I don’t mind.

I have found for long heavy full size sheets, my Mafell track saw wins out over my table saw due to my shop size and trying to handle the sheets with 1 person.

For small stuff, the table saw sled is great for accuracy and repeatablitity, but you really need an infeed, outfeed and extended fence for large stock on the table saw (or a good sliding table with clamps). That means more shop space for the table saw.

A panel saw might also be an option, but I don’t know too many people that have them in their personal shops.

A table saw will make parts smaller in places if you twist, but every part will have the same exact maximum size. That is by far the most important part of a torsion box, small smaller imperfections will be hidden with glue, any slight oversized deviation in the ribs will result in a very poor torsion box.

Also, let’s not overthink it here. I am just trying to make an easy, fun, good looking table, that is better than a 1/2"sheet of particle board on a table.

In the end it will still get surfaced.

https://docs.v1e.com/mpcnc/Ptable/

This is the current table building instructions…from 2015. It has not been updated because we always end up in this cycle of…“it won’t be perfect”

Ain’t that the truth.

I like endstops, and use them regularly, because I like having repeatable stuff when something fails but is recoverable.

I’m not chasing a lot of zeros though, I trammed my Primo to be able to use a surfacing bit in it, but for the work, not for the spoilboard. I surface a small piece of scrap when I want to mill a PCB. My LR3 was adequately trammed when assembled (Though I’ve changed the router, I should check it again…)

Lasers

Also I’ve noticed lately, well, maybe the last 5 years or so, no one want’s to read the docs. They want a youtube, or tictok, or some other bullshit other than the docs written by the $thing maintainer.