No the tension arm bearings die.

Yes, I have but I’ve also learned how to slice a little bit so now the door has opened a little wider on things for me to actually print and I’ve been going to town!

Personally…

and this…

So I can hopefully actualize this too…

Cheap carbon fiber supplier anyone?

100%, but in terms of this whole project, 3D printers are starting to take up the largest percent of my time. I would rather play with more CNC Router things, and learn on that front.

Playing with klipper has taught me a ton, it was great to learn, maybe I should have spent more time in fluidnc though. I can say with absolute certainty I know more about klipper than Fluidnc and that feels pretty wrong to me.

want my address??

lol

I am still waiting for the Core One upgrade release… ![]()

On a hunch I just checked, it is available…

And yes, that’s half the price of a new printer and nearly as much as your printer… -_-

But I like Prusa and am going to continue to support them. ![]()

Honestly, now that I have had several printers become obsolete, I wish I had an upgrade path for all of them. This seems like a great way to stay in the ecosystem and not have the guilt of old printers sticking around.

I also really like that approach. You could have gone from the first version to this one. This upgrade is expensive, sure, but there are a lot of changes and half the hardware is being replaced (moving bed, frame, etc…).

When the MK4 was released people complained it was a bedslinger and that it was a dead end, but Prusa said they wanted to keep the upgrade path available. I am happy they found a way to the CoreXY. ![]()

And then they went and bought a zillion Bambu (we’ll never build a bed slinger) clones! ![]()

In the case of the Mk$ I really don’t want to waste those lovely cast aluminium parts, but I can’t say that too loudly around my wife or she’ll make me give the whole shebang to one of the grand kids and then I’ll have to buy a whole Core One instead of just the upgrade.

I actually thought about trying to make another printer out of them or some other fancy contraption. ![]()

This is already addressed by Ellis’ tuning guide and thousands of Reddit and Voron community posts

[“ For idlers, there is some debate over toothed vs smooth. My personal opinion is:

- Gates toothed idlers > smooth idlers (2x F695 bearings) > china toothed idlers” -Ellis](VFAs (Vertical Fine Artifacts) | Ellis’ Print Tuning Guide)

I will confirm that this is true as will thousands of others.

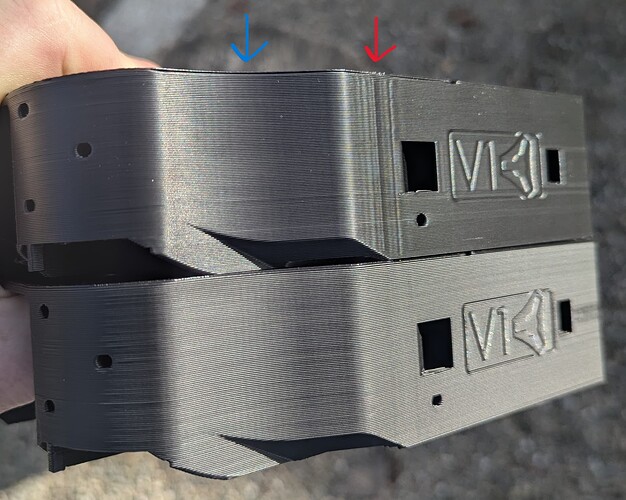

I thought you all might find this interesting. The top print is the Qidi plus 4, the bottom is the MP3DP v5. Blue arrow shows where to zoom in to compare VFA, red arrow is just the worst spot I could find (mostly a slicer issue not really a print issue).

Print times are probably within 10 minutes of each other.

I will say the MP3DP v5 looks a couple percent better overall, but the cheat here is I am using a more matte filament from tangled. If I print it really slow the glossy part looks slightly worse. So Matte is your friend for nice surface finishes.

Your MP3DP v5 prints look really clean to me, even if the matte finish is helping a bit. Nice!

Using a E3D Hemera 0.6mm nozzle, and PowGE RF-Yellow or RF-Brown GT2 9mm belt, your regular 84oz 1.8deg steppers, 24v power?

All the standard parts from the shop, that print was done with a smart orbiter extruder.

I just revamped the other V5 with an orbiter and the other belts so I can finally conclude my VFA test this morning.

My biggest issue with my MP4DPv4 has been the raspberry pi running octoprint. I have all the parts to convert the printer over to klipper and a manta board. I just need to get around to doing it. Otherwise, the printer has been pretty solid since I’ve replaced the 3d printed core with the aluminum one.

Oh. And the current roll of PLA I’m trying to burn through is crap and keeps breaking. Not sure if it’s the temperature or the humidity in the shop causing the plastic to be brittle.

My V4’s are all still running strong, the v5’s are just faster, honestly mostly because of the extruder. I changed out one of my hemera’s to a 60W heater and a CHT and that one is pretty good.

I need to make a choice here soon though. Slicing things for 3 different printers is lame.

Cant say enough good things about klipper. If octoprint is struggling on the pi, that might be an issue for klipper though because it runs on the pi as well. I’ve had stability issues with one pi and klipper, but i believe it to be hardware related, not a klipper issue.

I open up separate instances of Orca slicer and connect to each printer. That way whatever I am working on slices and uploads to that printer.