I have been following along with the Qidi builds for a while now. I was interested in the fact that they used only a lightly modified klipper build that you can still easily edit. The price dropped right while I was researching a new extruder hotend combo for my 3rd MP3DP V5 build…and well it hit me like a ton of bricks.

This printer comes with more features, pre-built and costs less than I can build one of my own printers for. That stung pretty bad at first, I was pretty bitter about that. After a few days I came to realize 3D printers have finally hit “tool” not “project”. That makes me pretty happy, actually. I got to follow along from the very early days to a product that is excellent right out of the box, that makes me smile.

Affiliate link for all Qidi Products.

Okay let me try to run this down to a basic list.

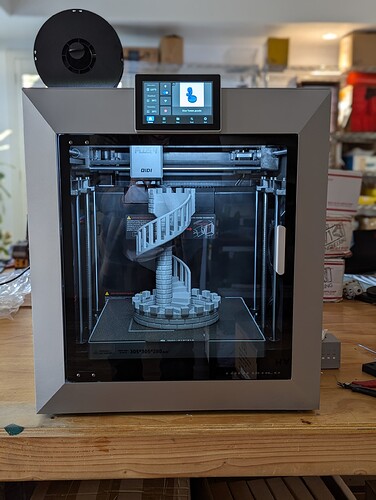

25mm^3 in PLA (~13min perfect benchy)

Large print volume.

Hardened extruder gears

Hardened nozzle

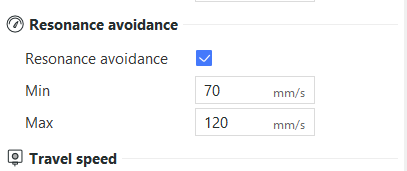

Accelerometer

Runout sensor

Snag sensor

Filament width sensor

Filament cutter

Nozzle cleaner

Camera

Large touchscreen

Double sided bed

Preconfigured

Square in all planes to a very high degree

Preassembled

Heated chamber

Good print cooling

Across bed cooling for even more advanced parts faster

2 point bed leveling, plus mesh level

Inductive probe and piezo sensors

inexpensive replacement parts

Good customer service (had a damaged part they shipped a new one next day)

Hopefully a filament changer solution soon.

The only thing my MP3DP v4-5 can do this can is non-planer printing. Well we all know that is not soon to be on the horizon and so far does not seem like it would be all that useful either, yet.

This is a printer that has more than my custom build, same print speed, far more features, to my door and printing in about 15 minutes, for less than I can build my own.

Since it is not really worth me spending much time developing another printer I can spend more time working on the CNC’s and Zen. I do love messing with printer designs for some reason but this is the first printer to have everything I want and then some…for less than my bulk parts cost, and I do not need to spend several days building and calibrating it.

I am going to start beating this thing on the print farm before I buy any more but I can say I am fairly certain I will be buying more of these to expand my printed parts offerings.