(allow me a mildly didactic tangent for a moment) It’s important to remember that several generations of smart engineering folks have been working on CNC and gcode for decades. Chances are if you’re coming up against a problem for the first time, someone else has already solved it. The down-side is, the “by the book” solution probably has a whole lot of (really cool, if you need them) esoteric options that it can be tough to wrap your head around. It sometimes takes investing some energy in understanding some pretty dense documentation for it to truly make sense.

If you use work offsets to set the interior location of the job, this work offset is understood to be in relation to the overall machine movement envelope and soft limits will be honored.

(on a slightly different tangent, bear with me. Sorry if you alreayd know this, but not everyone who might come across this in a search will) The micro switches usually used for end stops have 3 terminals. When the switch is in its resting (normal) state, the Normally Closed terminal is electrically connected to the Common terminal, and the Normally Open terminal is isolated from the Common terminal. When the switch is triggered/activate, the NC terminal loses connectivity to Common, and the NO terminal gains connectivity to Common. Under normal use, NO and NC should never have a connection between them.

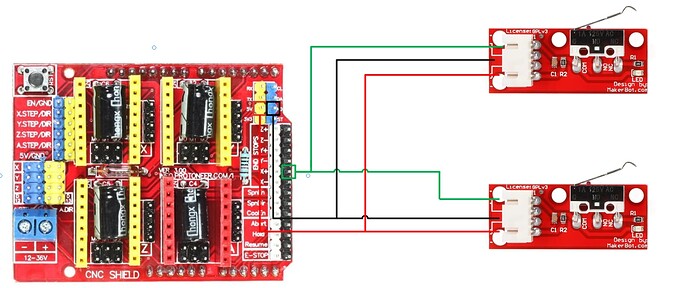

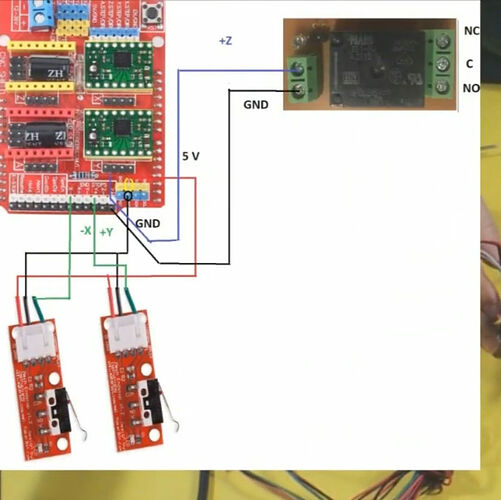

(now to answer the question you actually asked - thanks for your patience) As far wiring the switches, “signal” (the NO or NC lug) connects to the white pin and “common” (the COM lug) connects to the black one on the shield. If you’re using simple switches it doesn’t really matter which is which, but if you’ve got those 3d printer endstop circuits, or a PINDA probe or hall effect sensor, or something else that needs a reference voltage, then it matters. You can get that refence voltage from the 5v (yellow) pin you identified in your picture.

If you go with the first diagram on the Wiring Limit Switches page I linked before, you’ll only have 2 wires to connect to the shield for each axis, so one to white and one to black on whichever axis it makes sense for. Notice how tripping either switch opens the loop by breaking the connection between signal and ground. Grbl notices this change in state and takes whatever action has been defined.

You can also use one or two NO switches per axis, as in the second image. On the shield, this would look like each switch having 2 wires run, one to white and one to black. Notice how now tripping either switch establishes a link between signal and ground. Unfortunately, while there may be two physical switches, they both result in the same digital signal, so the shield, and therefore grbl doesn’t actually know if was - (min) or + (max) that was tripped. In this case, grbl decides whether it was min or max that was tripped by knowing which direction the axis was moving. For example, grbl supposes that if X was moving in the + direction, it must have been X Max that tripped.

You use the $5 setting to tell grbl whether you’re using NC or NO switches. It expects all axes to use the same type.

You’re right that it is safest to have a switch at each end of travel. It’s also safest to use NC switches, the rationale is spelled out in the Wiring Limit Switches page.