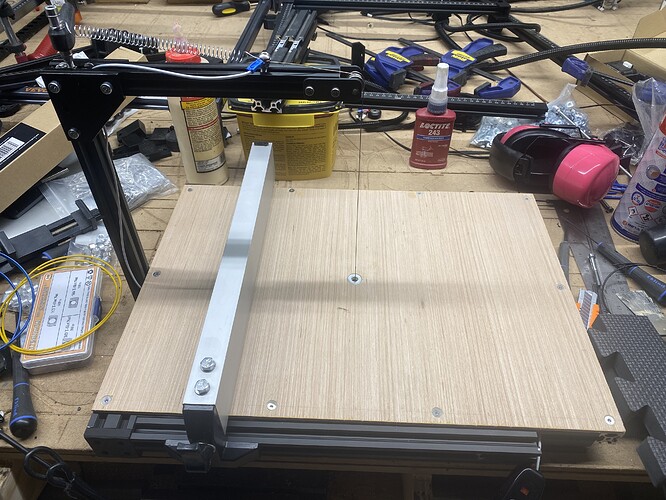

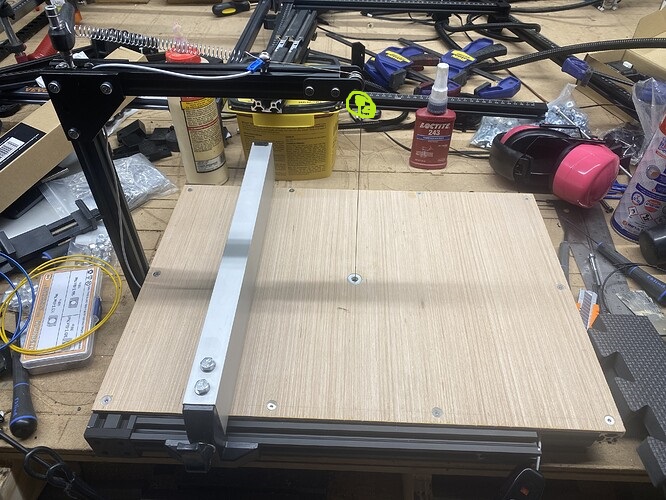

I finally made time to build a hot wire foam cutter - meet the “MWLFC” - i.e. “made with leftovers foam cutter.”

Pardon the chaos on the LowRider table— I’ve got quite a few projects in the works.

I’ve ordered for this thing an affordable DC motor speed controller, aka PWM controller, so I can adjust the heat level. In the meantime I can cut with it briefly, but it gets too hot fast, so I’m holding off until the controller arrives.

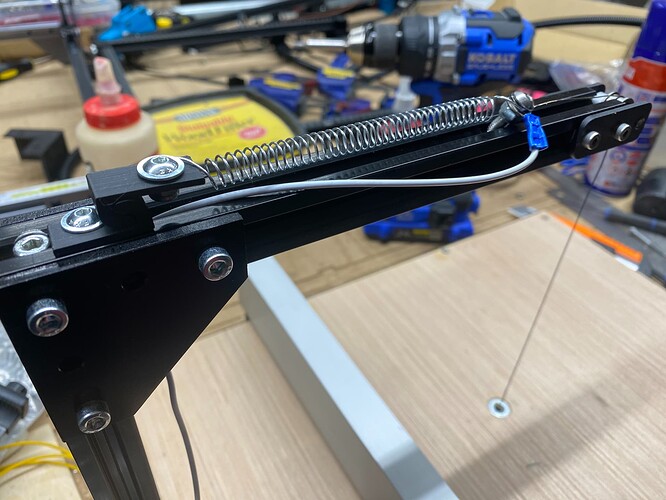

However very little was bought expressly for this. Besides controller, the only other thing was the 22g nichrome (80%) wire, which I bought a year or two ago with this in mind …

So, here’s the leftovers list:

- Scrap 1/4” plywood

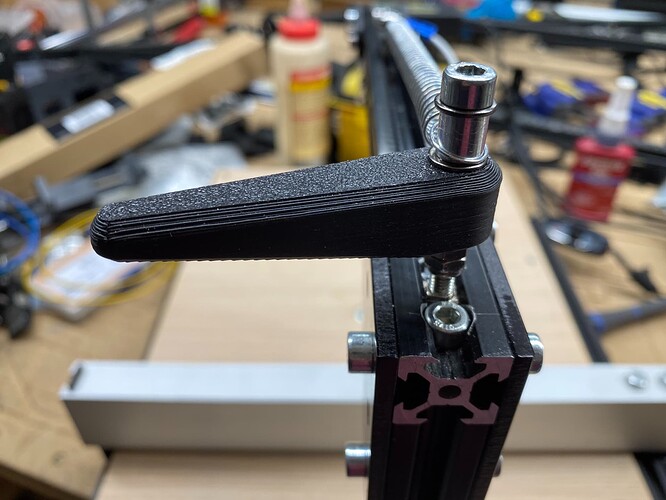

- Aluminum extrusions that used to be an Ender 3 v2 — plus another bit of scrap from a different printer project

- 12v power supply that used to power my LR3 router CNC

- Switch that used to turn the LR3 on and off

- Scrap of plywood so small you’d think it would never be useful (LOL)

I’m getting double duty from the rip fence that came with my VEVOR Bandsaw. I carefully checked the size and made sure it would work for this before I built it.

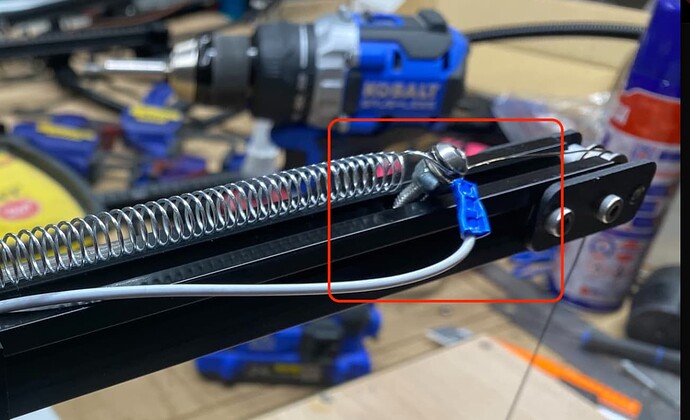

I used various other items already in hand in my shop, including wiring, screws, t-nuts, the spring, spacers, crimp-on connectors, some bits and bobbles.

Given the major use of leftovers & in-hand stuff, this is one of the lowest cost projects I can remember in a while.

Also, I found an affordable source for an ample supply of high density EVA foam that is 3/4” thick, and it is those interlocking floor tiles used for gymnasiums and people doing yoga exercises. The best price I could get on it was a package of four tiles, each 2‘ x 2‘, for only $20 from Target.