Dam I have to say once you see one of these running, everything else looks pretty bad. This thing is taking abuse (and it can take more??). 25% gyroid infill at 105mm/s dumping lines at 27mm3/s, and sounds like a fine tuned machine doing it.

Nice to see your v5 zooming through the filament.

An even more evil me would invent and market gyroid infill to be a cool hip infill. While I secretly reaped the rewards from sales of replacement parts resulting from the torturous wear the infill inflicts. Noisy too?

Maybe I’m old fashioned, but triangles and hexagons infill look cool to me.

Are you thinking of a mostly printed and cnc’d metal brake? Might be better to plasma cut parts for that project.

What do you think about Ender 5 plus into v5?

Looks like a total rebuild, it gets you a few of the parts but I am not seeing much that is going to be reused other than extrusion and hopefully extruder and most of the electronics. I would guess that get you a little over half way there. I have no idea if the extruder and electronics are worth it or not.

only if you are happy with 10mm^3 or less… not worth it

![]()

If you aren’t going to replace to a better extruder, it’s probably not worth the effort or money

Agree 1000%

For the Ender 5 the Mercury One.1 is probably your best bet. If you want a V5 (Highly Recommend!) then start from scratch

What hot end did you put the cht nozzle on?

Standard H2 V2s

And it tripled your max flow?

Guess I need to add that to my list.

No. My Hemeras with brass nozzles can do ~12mm3/s, the H2 V2S with a carbine nozzle was doing ~18mm3/s, this CHT is hitting ~27 sustained (it peaked above 32). So just double depending on witch one you look at.

The H2 lite is rated for 45mm3/s with the brass nozzle, but I wanted hardened but not all hardened steel. So I did not want to convert that to a regular nozzle and all that…for now. these speeds and flows seem incredible to me, but they do also seem much harder on the printer. So I am going to let this go into production soon to see how it holds up. These accelerations and speed shake the table a lot, I can only imagine how all the parts are going to hold up after 24/7 printing.

I will ride this one out for a while, and maybe throw the Lite on the next build to see how it runs for few tests.

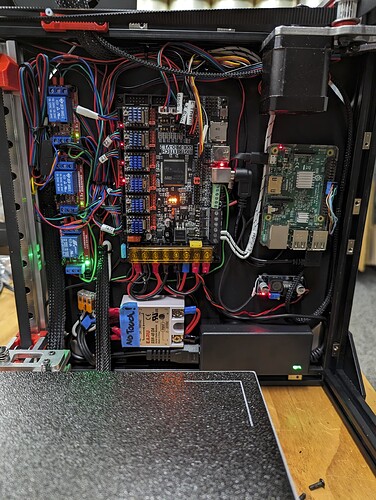

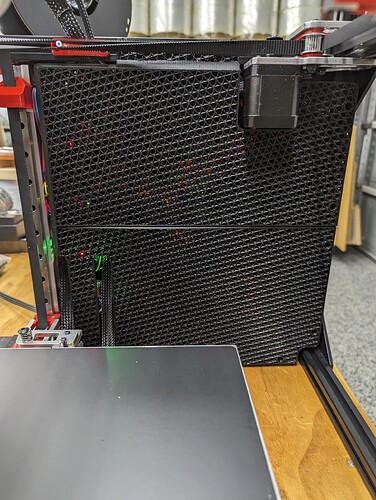

- General update I had a snag had to reload klipper so I got delayed a day. I am doing some of the last calibrations and tuning. I will print two new electronics cover panels, then take some pictures ASAP. At that point it is probably time to start the release process…slowly.

Skew in XYZ skew tuned, retractions tuned (waiting for kerf seams to go ham on that), Accel tuned, max flow, Max speeds inching higher and higher, z offset, mesh, PLA temp tuned, heck I have even been tuning support material.

I am printing new electronics covers now (cubic infill this time, no more gyroid for me).

Might work on orienting the part files for the release. While these print.

Then. Start playing with the CF PETG.

WOW, you can watch the filament roll spin as it prints, it is constant. WHOA.

Looking good!!! I got a few more parts cut for mine today but still not far enough to be worth a thread yet. Hopefully very soon!!!

Okay, did a quick CF-PETG test…not rigid enough. I will print something more substantial just to make sure but I have a roll of PET-CF on the way.

Whats not rigid enough? Were you trying to print the metal parts??

No, CNC parts. I am sure the next printer will be made for this stuff but to make a “premium” CNC printed part I am looking for something more rigid than PLA. Turns out, not an easy ask.

would you settle for something just as rigid, but not as brittle?