There well could be.

I didn’t like them much at first, but my cousin’s son got an Ender 3 which he didn’t get set up, and it took me very little time to get set up and working well. He’s been using it a year and a half and it’s holding up.

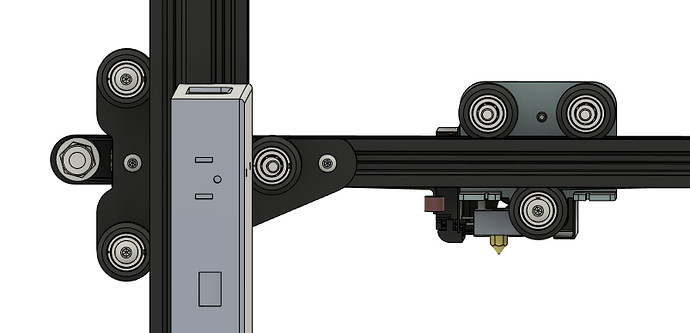

For my laser, it didn’t seem feasable to get 1.5m rails, and the OpenBuilds carriages were inexpensive, so I decided to try them. I have 2 of those carriages and 1 of the Ender style ones and they were pretty easy to get moving smoothly. The difference in cost was much bigger dealing with a couple of 1500mm and an 800mm rail.

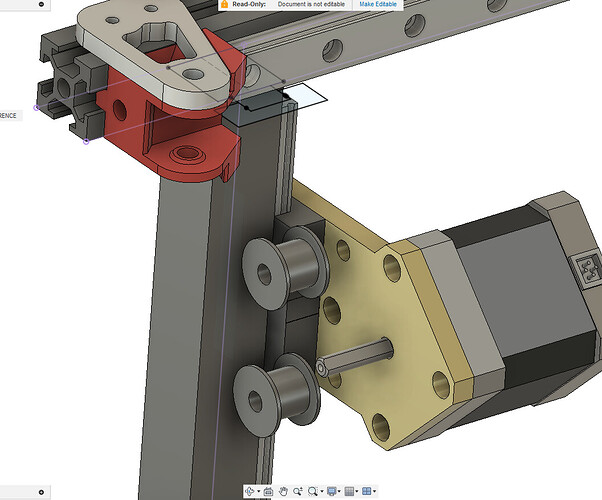

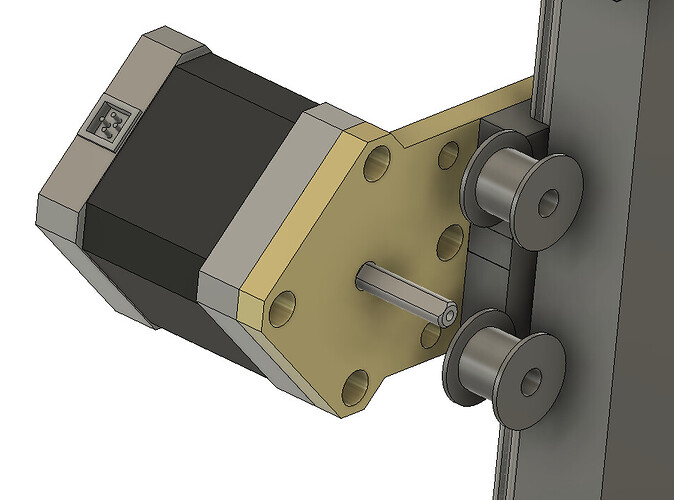

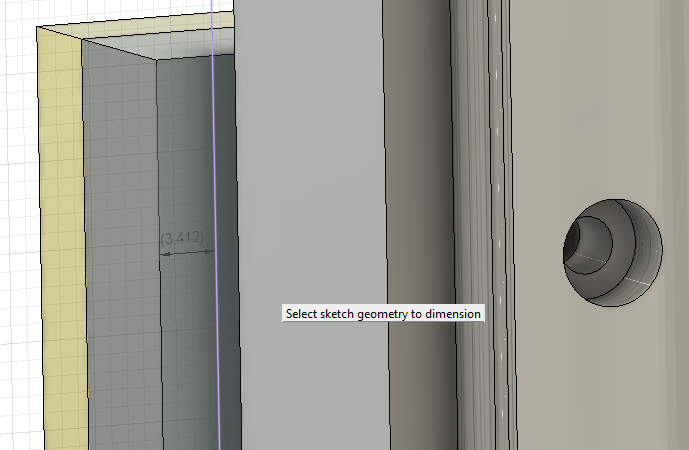

So far, so good. I think I can do better with alignment of the motor pulley with the belt inside the extrusion, sometimes I can hear it touch the sides, but it hasn’t caused skipped steps at all.

The laser goes to 12000mm/min and seems to work well. I’m in the process of moving it over to the Jackpot, but on the Duet it seemed pretty good overall. To where I am having trouble I think because the laser output isn’t keeping up in raster mode, I’m getting blurred edges. We will see if the Jackpot fixes that.

For me, I don’t remember them being “everywhere” but I mostly looked at budget stuff, and it was the M8 smooth rod and LM8UU bearings that were everywhere. I still use that as a solution, too, because it’s ubiquitous and cheap. For me though the fact that it’s still around in places like the Enders and the OpenBuilds machines seems to me like it must work at least reasonably well for many people.

Anyway, the investment is low so I’ll build that way if it’s an option, and if I don’t like it, I’ll swap in rails.

Considering that I do not need another 3D printer, and this will be a “gotta build 'em all” project for me, lower cost here means more money for other things.