It’s really common for napkin calculations in physics. In grad school, they like to test you with crazy questions like the probability of a neutron hitting a nucleus in a gold foil and you get to make up an answer using mostly dimensional analysis and a few estimated constants.

we call it “dimensional analysis.” if the units dont cancel so you end up with what you want, you did it wrong. That was how I got through chemistry class… invert stuff until the units worked out.

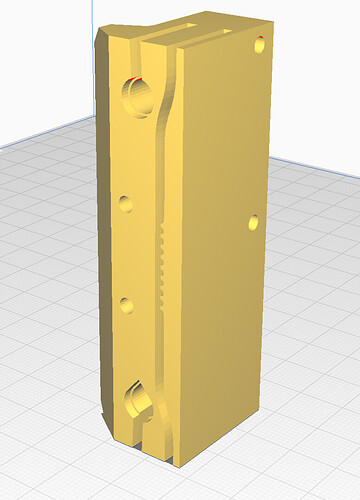

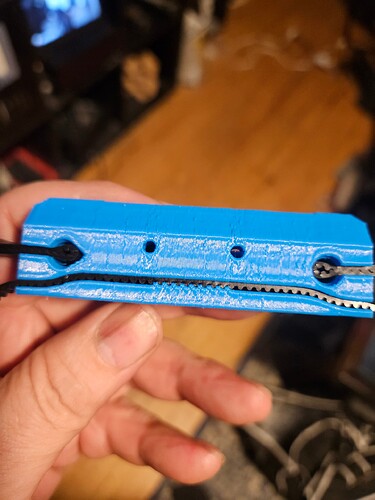

That screw in the far right of this picture just has a belt wrapped around it. This fits real nice.

Bottom half feels good now.

Just in case I will make the crossover belt gap a parameter to easily adjust.

Just need to finish up the XY tensioner and the XY is mostly done and ready for some test prints shortly.

HCore Bottom.3mf (88.6 KB)

Anyone want to do a test fit?

Anyone want to do a test fit?

Damn I wish I was home to try it out!

Anyone want to do a test fit?

Now printing…

Doh🤦♂️, thanks @Jonathjon!

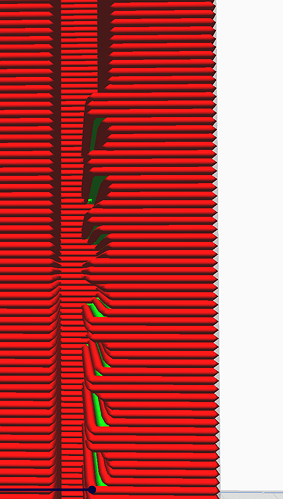

Will see if my printer’s 0.6mm noz, 0.3mm layer height, inside walls first is tuned enough to make decent belt teeth…

Worth a shot. But worst case print it again with a lower layer height to get more resolution. You can go down to a .2 or less even with the .6 nozzle. But I’m pretty sure Ryan prints with a thicker layer height so you should be good at the .3

But I’m pretty sure Ryan prints with a thicker layer height so you should be good at the .3

I think he prints with a 0.5 nozzle. From the picture, I’m going to guesstimate a 0.3-0.32 layer height

Let’s see if I win anything ![]()

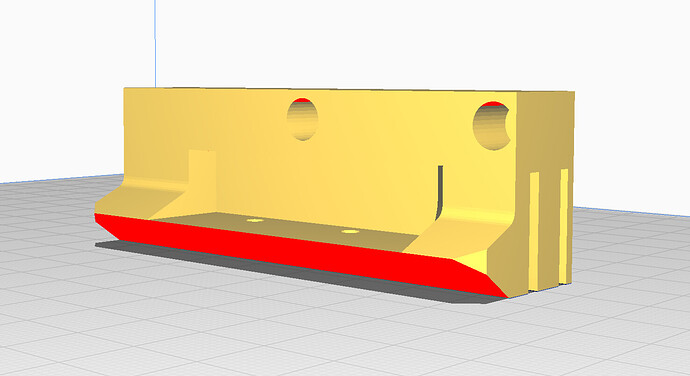

For clean belt slots, do you want us printing like this?

nope

Will see if my printer’s 0.6mm noz, 0.3mm layer height, inside walls first is tuned enough to make decent belt teeth…

I used 0.38 layers, fits too good.

That never gets old.

I made that this morning printed it and you already have one in your hand…freaking cool.

Thank you for checking!!

I am going to call it a night and print all teh new parts to assemble a test top

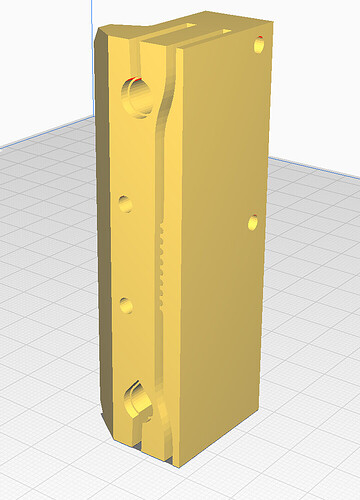

Is there a reason one bolt hole is spade shape and one circle?

reason one bolt hole is spade shape and one circle?

Print without support?

Print without support

This was my guess when I noticed it as well

Print without support?

Winner!!

reason one bolt hole is spade shape and one circle?

It’s winking ![]()

I made that this morning printed it and you already have one in your hand…freaking cool.

I always love the feeling of holding an object that only existed in my head hours before. I don’t often get the experience of knowing that something I designed like that is in someone else’s hands though.

Looks good, and holds up well to me. Thank you for making holes large enough for flange M3x10.

Do you have a target pull/weight limit?

20%, 2 walls, weight limit unknown, but working on it… (Dead load?)

EDIT: Overture silk gold PLA just because that’s what was loaded, and will help show print flaws. Added 5lb increments all the way up to Max weight of my LR3 hold downs, which is 52.5lb. v5 proto type Core is still holding…

Will leave hanging for a bit to see what happens. Indoor space is 66F.

Shared gcode (which includes settings in comments) on GitHub