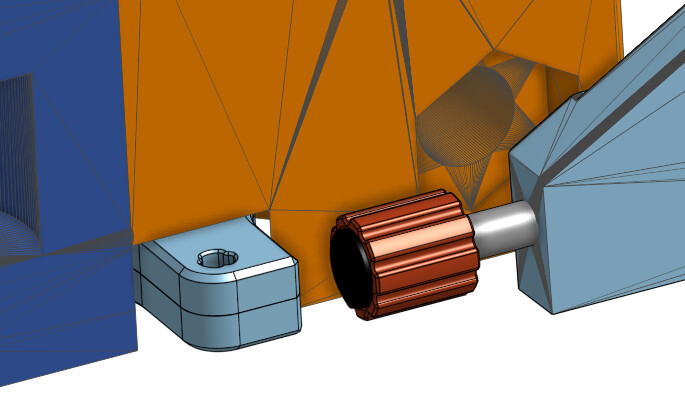

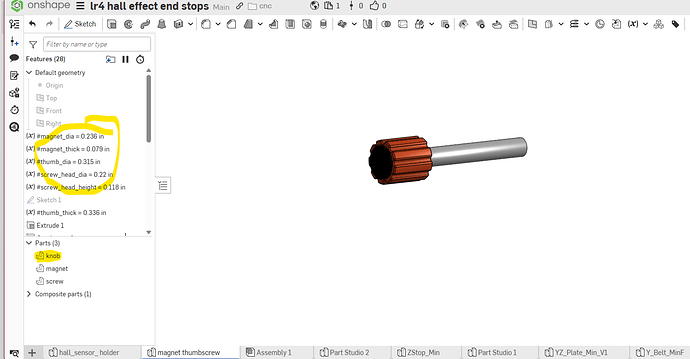

And I’ve added a parametric (not thoroughly tested) adjustment knob. Which mounts a magnet to an m3 cap bolt and nut.

Man David, you are on ![]() .

. ![]()

If by on fire you mean avoiding the things I should be working on then you are correct!

Well, that’s how it works, isn’t it? ![]()

@which_carpenter Looks great! I downloaded the earlier version too, but I like this even better. Nice!

is this available also?

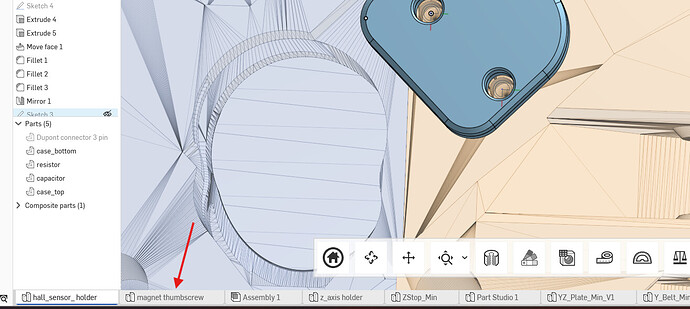

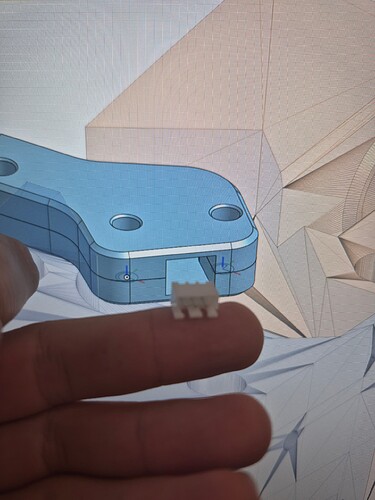

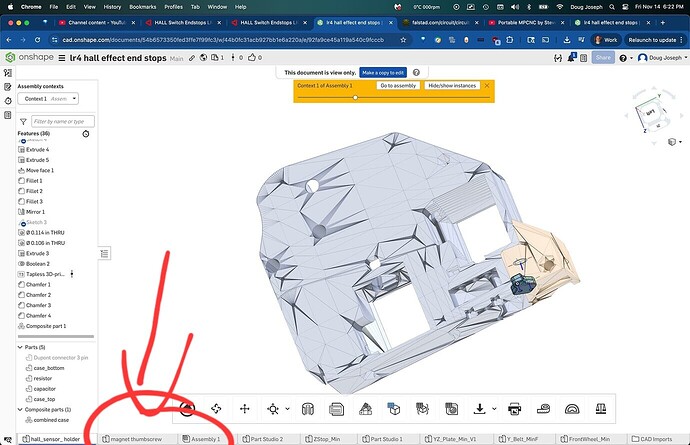

yeah, it’s in the same document. The tab is magnetic thumbscrew, then you can change the variables on the upper left to match your parts. Hopefully the names make sense. You just need the diameter and thickness of your magnet along with the head of your screw. To assemble you pop in an m3 nut, thread in your screw, then glue in your magnet. That’s the plan at least. When you’re ready right click the part knob highlighted below and export as an stl or step.

Will this drop in for the switches on the other axis?

Also, could we/should we orient these in such a way that they pass by a magnet instead of crashing directly into them?

oh just click the tab called magnetic thumbscrew on the bottom. If that doesn’t work maybe I shared only one page of the document.

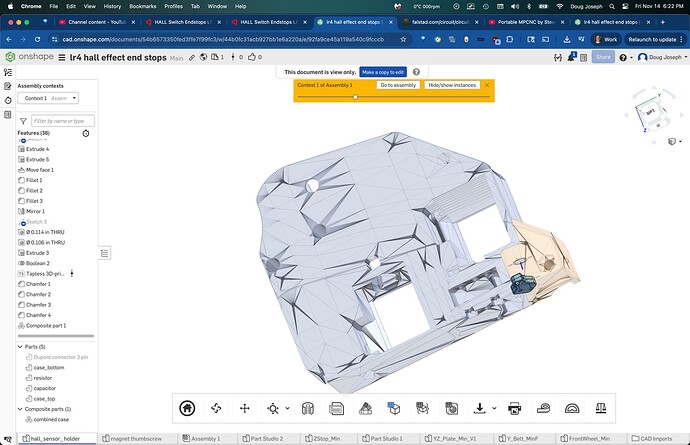

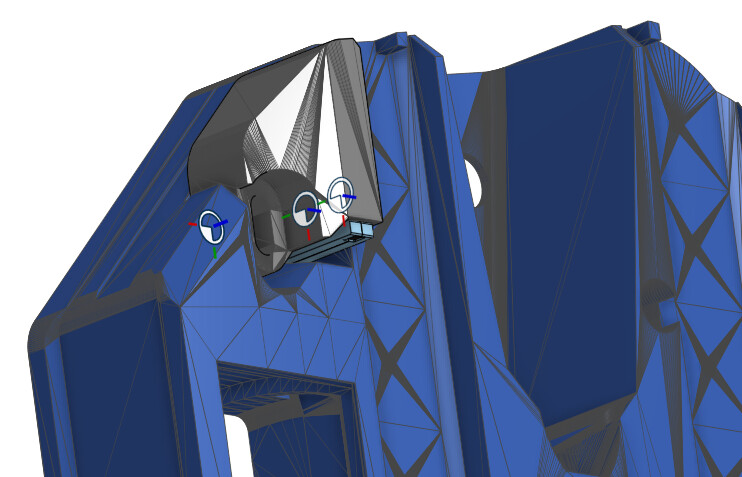

Just finished a draft for the z axis under the tab “z axis holder”

I don’t see anything with the word “magnetic” on the interface anywhere.

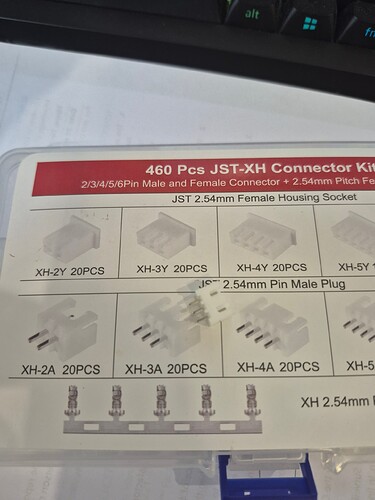

Im out for the day, but i will print the housings off and then try and model it to fit the 3 pin JST housing to fit in maybe with a bit of a blank breadboard i got laying arround

Sorry @DougJoseph I am out and about, and thought the first post didn’t upload. Sorry about the double up

Argh. Yes. How did I miss that?

Do you have an idea for the magnet holder on the plate for the z?

Looking at locally available alternatives. Would the following be acceptable?

A3213 Hall Effect Sensor

Features:

-

Micropower operation

-

Operate with north or south pole

-

2.4 to 5.5 V battery operation

-

Chopper stabilized

-

Superior temperature stability

-

Extremely low switch-point drift

-

Insensitive to physical stress

-

High ESD protection

-

Solid-state reliability

-

Small size

-

Easily manufacturable with magnet pole independence

Datasheet https://www.allegromicro.com/-/media/files/datasheets/a3213-4-datasheet.ashx

Glue haha

Simples! Love it

I think that would work fine. I note (p.8 of datasheet) they use two caps, not just one. They have a 50k pullup, which is a very weak one, to save on battery power. Not our problem, so stick with 1k pullup for better noise immunity.