Also, where did you get the config for the MKS?

Thanks for doing that, Tony (and for your help too, Tim). And yes, it was following the same path on each layer that it was cutting. So it must be something wrong with either my GRBL configuration on my controller, or something with CNC.js.

As far as the configuration goes, I pulled it from the LOOOONG GRBL post in this forum. I think this one:

I don’t remember which fork I actually took, and if I recall correctly, I had to massage it anyway to finally get it all lined up. Seems to me it had the X2 and Y2 axis labeled as A and B, which was causing the “extra” stepper motors to stay stationary when the “original” stepper motors did their thing.

C

Thanks! Lots of smart people here, so I don’t get to help as often as I’d like and take whatever opportunity I can.

FWIW,I ran it through cncjs desktop app, so you can probably rule that out, too.

I don’t know what it means for the controller to be esp_32,and I’ve never even seen the board you’re using. If it were me, I’d head over to the software /firmware section, maybe under the mks section, and start up a new post. Include the mess all the way up to us testing the code on a different machine. Maybe someone who knows those boards and/or mega 5x can help, but skips this thread because it says “rambo”.

Thanks for the input, all. With your help, I was able to figure out it was a firmware issue. I had $11=0 and $12=0. Changing the $12 to 0.002 seems to have fixed the issue!

C

Wooooooow. That is TOTALLY not what I thought $12=0 would look like!

Glad you got it sorted!

I had no idea what to expect, but I’m super glad it got sorted out too!

Next steps…

- Figure out how to get my z-probe wired up. The cpu_map.h file has the probe assigned to bit 7 (analog pin 15), but I don’t see that on my pinout diagram.

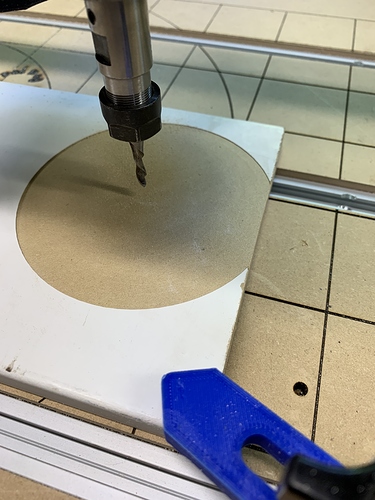

- Level my spoilboard. On the 100mm circle, there’s a variance of about 0.4mm from one side to the other. Maybe I better check my legs are all firmly seated… That seems like a larger difference than I would expected. On the plus side, it seems to be well trammed, as the bottom of the circle was very nicely flat.

- Actually make something useful/functional. So far, it’s been pretty much all test cuts!

C

When you disable arcs, are there still G2/G3 in the gcode? It looks like you fixed your arc config, but guffy would probably want to know if his post processor had a bug like that.

I confirmed it, still G2/3 moves. Started with the simplest circle I could sketch before attempting to troubleshoot, thanks to advice from guffy himself after my other issues that weren’t actually arc related.

I wonder if it’s not a bug because my other grbl pp does the same thing.

@guffy. In case you weren’t aware.

Yes, it was issue for GRBL only version. I had not hear about any problems with arcs in GRBL, so I have no idea why it cauld be handy.

but anyway it’s fixed now

Grbl arcs are so SMOOOOOOOTH

Just getting caught up on this thread. I also would love to run GRBL on my MPCNC. I’m not a computer science major, but have a tiny bit of experience with the Arduino IDE and making edits. I do have to admit that I did get a bit lost following some of the troubleshooting in this thread. Would someone mind making (or pointing me to) a basic step by step to get me up and running with GRBL on my RAMBo? Thanks!

- get rid of the grbl folder in your arduino library. I saved mine in a different location because I already had made changes for a different machine. You can always download a vanilla copy later, so if you don’t have any work in it, it’s safe to delete.

- download the grbl linked above. I think the original link has been updated with one or two fixes, but I could be thinking of the 5x thread. Been so long…

- unzip and move the grbl folder into the location for step 1.

- plug in your rambo and get all the libraries and stuff if you haven’t already (same as in the V1 docs for firmware).

- open the arduino IDE and make sure your board is connected and communicating

- open grbl from the arduino examples

- upload to your board

- get cncjs or repetier or ugs or some other gcode sender (i even moved mine with lightburn when repetier was giving me fits).

- connect your board to the sender, see if it moves, and let us know if you need help troubleshooting.

The version linked here works really well. I don’t think i had any trouble until I tried switching to inches, which I eventually figured out.

I took a quick skim through some of the later posts, and it looks like you had trouble with the digipot settings before. I’m 99% sure they’re at the end (bottom) of the config file, and also 99% sure you can set change then from the console with a ‘$’ command.

Hey guys, I’m trying to flash this firmware onto the RAMBo 1.4 and I’m getting some errors in ArduinoIDE

#error "Required HOMING_CYCLE_0 not defined

#error “WCO refresh must be greater than one.”

#error “Override refresh must be greater than zero.”

Anyone have any ideas on what to do to fix this?

I’m not sure what the refresh stuff is, but if you search the config for him) “homing” you duos be able to find the cycles. They’ll have things like “&&” and “||”.

Make sure that the homing cycle you’ve chosen homes 0 (first axis, i think…x1?). I could be wrong, so you want to verify near the top where you assign the axes, but I think x1, y1, z, x2, y2 are 0,1,2,3,4 in order.

You can home multiple axes in one “job” or cycle with GRBL. Cycle 0 will be completed before cycle 1 is started. Default approach is to home Z in Cycle 0 (usually to a Z Max switch to prevent crashing the tool into a mounted work piece), then home X and Y in cycle1. You can set up your own cycles, but I think you have to start numbering at 0 for them to behave properly.

Hey guys, thanks for your help! I realized I had the setting as an Arduino Uno instead of an Arduino Mega. I still got error codes, but it let me upload it to the board. Real big facepalm moment there.

Hey, ya’ll! Time for another GRBL question…

So I’ve had GRBL running on my MKS Gen 1.4 board for awhile, and it’s going ok. But… I don’t think I’ve got my microstepping set up correctly, and that’s affecting the speed my MPCNC can move. I’ve tried setting the max speed to ridiculous values ($110 = 12000, or 200 mm/s), and it continues to plug along at about 40 mm/s. My initial values were 3000 (or 50mm/s), and I’ve also tried lowering it. Lowering it to 1200 (or 20 mm/s) does actually affect the speed it moves, but setting it higher than 2400 doesn’t make any difference. For laser work, it would be nice to get it up to 100mm/s, if I can.

My guess is that my microstepping is set to 1/256. But for the life of me, I can’t figure out where to set that. I’m using an MKS Gen 1.4 board and TMC 2209 (v1.2) driver chips. There are 3 jumpers under each driver chip, all current shorted out.

Any suggestions on this?

Clint

I’m guessing you have them in standalone more? Grbl isn’t setting them via uart? They probably internally use 1/256 microstepping, but to grbl, look like 1/16.

Don’t think about the speed. Just focus on them moving the right distance. If you send a 10mm command, do they move 10mm, 5mm, or 20mm?

If you have the steps/mm right and you want more speed, pay close attention to the max federate parameter, but also the acceleration parameters. If you start skipping steps at high speed, consider a 24V power supply (I haven’t looked to see if your board can handle it).

I just plugged the drivers into the board. Didn’t change any modes. I think they are defaulting to 1/256th mode, yes.

And yes, they’re moving the correct distance.

As far as “more speed”, they’re not skipping, even when I set the max speed to 12,000. They just don’t go very fast. I used the stopwatch on my phone, and hit the button in CNCjs to move 200mm on the x-axis (no load), and timed it. 5 seconds, or 40mm/s. Doesn’t matter if my max speed is 12,000, or 2,400. It’s only if I set it down below the 2,400 that I can get it to move slower. So it’s like the motor is spinning as fast as it can, given the settings it has. In this case, acceleration shouldn’t be an issue, as it hits it’s max speed relatively quickly. But my acceleration is set to 50 mm/s^2.

In the Marlin firmware, there’s places to set the microstepping. I can’t find anything in the GRBL files to do the same.

And my board will take a 24v PSU, but since I use the same PSU for my laser and it takes 12v, I haven’t put in a new one. But I can bypass that if I need to. I could try getting GRBL running on my SKR Pro board, which can take inputs from 3 PSU’s (24v for the steppers, mainboard, and hotbed, I think), but that sounds like more work with limited benefits.

One other weird things is in Lightburn, there’s an option to do “Line + Fill”, used often for text. The line part goes back after the fill is done, and outlines what you burned. For some reason, I can have similar settings for the speed for both portions, but when it hits the “line” portion, it hits some sort of “hyperdrive” mode, and throws the laser around like a bull with a circus clown. I need to save the g-code for one of these types of files, and figure out what command it’s giving to do that. And when I did the “camera alignment mode” last time, after setting the max speed to 12,000, it does an outline of the number for each of the 4 alignment points. It threw the laser around so violently that it actually skipped a step. I don’t think it was because it couldn’t move fast enough, but because it was accelerating and decelerating so fast. But I can’t get the code for that example, because it’s an internal Lightburn function.

Ah, CNC’ing… Always something new to learn, right?

C