The spiral crown looks fancy.

A little off topic… But, this is the reason I had the image vectored. Messing with the laser at work. Can you guess where I work?

You are a hitman for hire?

Haha… not quite! More like a supplier for said hit man.

I would guess in working there you give a significant percentage of your paycheck right back! What a cool place to work.

haha yeah I have definitely spent a decent amount, but at 62.5% discount who wouldn’t!

Small update.

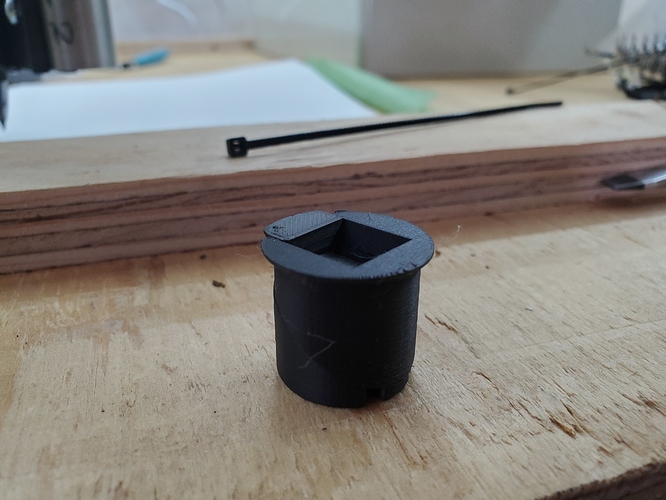

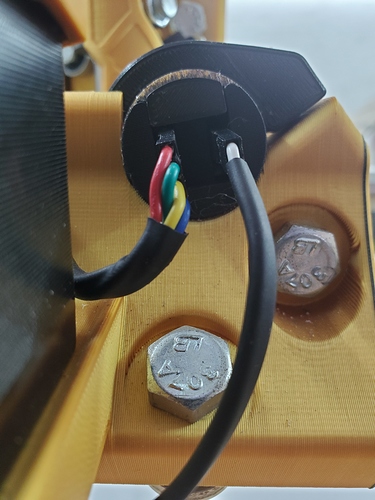

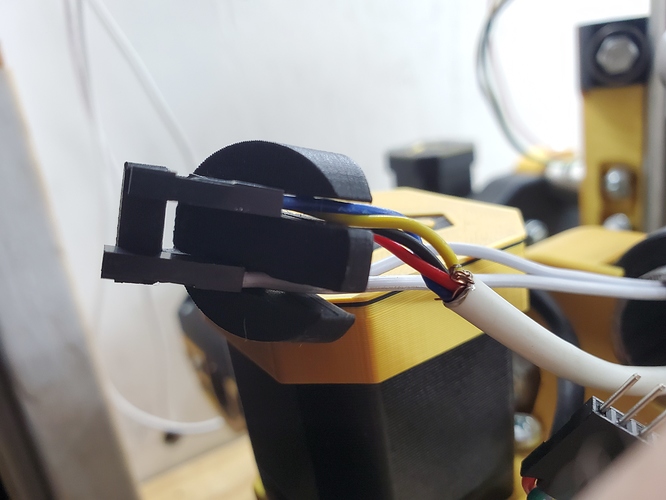

I added a few supports to clean up the lip that covers the tube profile and started the final print before I left for work. One for each end of the x and y tubes. Also I fixed that unhappy looking dupont 4 pin in the third picture.

Those electronic connectors look good. i was thinking of swapping the them out for aviation plug connectors that have the screw-lock

Yeah I will upload the file when I get a chance right now I’m about to head to work.

I can only imagine how long it took to get the grind right. I would like to think I can can handle a grinding wheel with confidence, but…now I know I am just a noob. The stack on the left looks a little scary, I have never seen one break, but I always act like it is about to happen.

I’ve only seen one break once… I was definitely questioning my profession for a couple days. Those broken ones on the left where broken intentionally after being removed from the machine. We use the jagged edge to dress the honing wheel which is leather.

It took about 2 1/2 years to get comfortable with all the models, blade shapes and different metals ( some of those super steels are pretty intense). I’m sure with your mechanical mind you could figure it out. It’s mostly just pressure and consistency that people struggle with.

@wellthad - that’s awesome. I’d love to know more about how that facility runs. I’ve forged a few knives but i’m trying to wrap my head around the mass production.

BTW, was very sad when Kershaw discontinued their TwoCan… my favorite keychain knife until TSA took it away (and then pocketed it).

There is a lot to describe. So here’s the short version Import materials, in house machined parts, out sourced coatings and finishes, assembly lines an entirely separate building for shipping a handling. Running it all about 300ish people between day shift and swing shift.

I am trying to get to that point I built my own forge even the torch heads. I ended up moving shortly after and it’s kind of been sitting in storage since.

Back on topic! So I’m nearly finished with wire management and I have hooked everything back up and all still works except Y2 doesn’t move when trying to home. Would this be indicative of having a bad endstop connection somewhere? The motor moves fine when I’m just moving the Y axis it’s only with homing.

I’d say the pulley is loose. At least it was in my case.

Checked that.