I ran into wobbly gantry issues on my MPCNC. I ended up having to redo the core. I squared the trucks without incident but after I put the core back on, the upper Y truck is always anywhere from 9-12mm closer to the top right corner than the lower Y truck is to the lower right corner.

I’ve redone the squaring without the core and got everything lined up again, but as soon as I put the core back on and try to square it, the issue comes back. Even when I tighten the core clamp closest to me as far as it will go, the gap still exists.

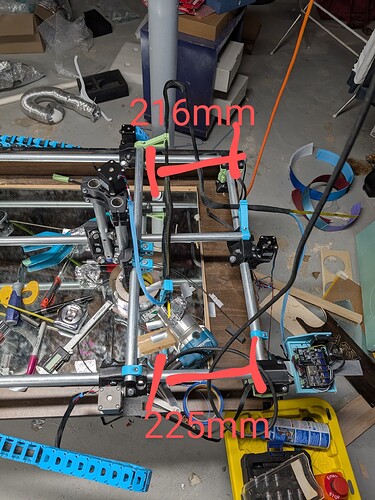

This image below is just the latest measurement after redoing the truck squaring. I’ve been doing nothing but squaring for maybe 10ish hours over 3 days and I keep running into this difference - can I get some concrete steps to do in order to fix?