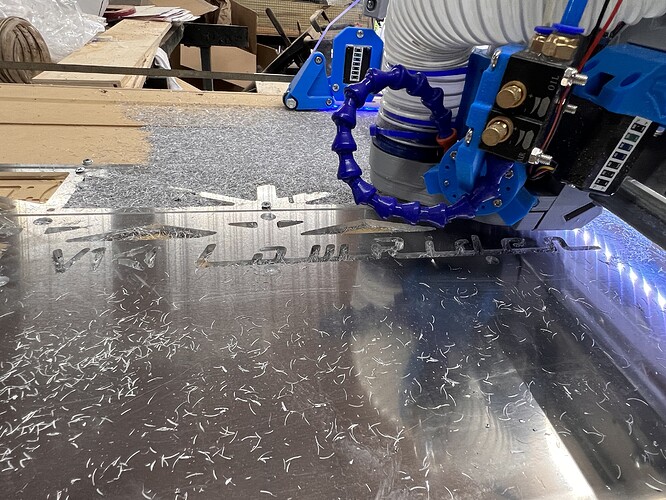

I agree this is an amazing photo. It has chips, action, cutting, and shows off the major thickness of that aluminum!

If you could “stage” a photo like this one but with the 3… but man, this is a great photo.

I agree this is an amazing photo. It has chips, action, cutting, and shows off the major thickness of that aluminum!

If you could “stage” a photo like this one but with the 3… but man, this is a great photo.

This also has both the LR3, the aluminum, the chips, the implied cutting… It’s portrait instead of landscape, but there may be need of that, and if not it could be cropped. But one challenge is that words are most readable when oriented like normal. One has to either turn his head or try to rotate this in the mind to read it.

Yeah it’s just not the same as the first one. I never can seem to get the right pics at the right time lol. Hell I should have been recoding all of this for a YouTube video but didn’t think to do that either lol

Is your dust collector off or are the chips too heavy?

Is that 1/4” aluminum? Damn

Now I’m jealous but don’t know enough to cut aluminum yet. Will keep watching ![]()

Dust collection is running but the mist cooler is working against it. I have an extremely fine mist of 99% IPA going to keep everything nice and cool.

Yes sir it is 1/4" And I’m cutting it in a single pass.

There was a time I didn’t know anything about it either. Just throw a piece on the machine and give it a shot lol. Check out @azab2c github page. He has a list of bits/feeds/speeds that are all tested and work good.

Trochoidal, trochoidal!!! Chant it with me… ![]()

Absolutely!! I use it for acrylic too

![]()

How much IPA are you pumping? Is it a steady state or computer controled?

Its just an amazon mist coolant setup. I have the air at 20psi on my regulator and just barely crack open the IPA. Just enough to keep things cool but it evaporates as fast as it comes out.

Technically it’s not mist it’s a minimum quantity lubrication (MQL) system.

well ![]() second time tonight the machine has been cutting along and then just taken off in a straight line. First time it did it down a clear path it had already cut. This time it was 3/4 of the way thought the FINAL cut and it took off home and broke the bit, then returned back and tried to start back where it left off. Said G?1 ******* on the screen. A few times it just hickuped in the cut. hung for a second then went back to work. No idea why its doing it and I’ve never had a cut do that before. Checked the gcode and everything seems like it should. That’s it I’m done messing around. Tomorrow morning the jackpot gets installed and we will see how it goes finishing the cut out. I have no doubts it will go well!

second time tonight the machine has been cutting along and then just taken off in a straight line. First time it did it down a clear path it had already cut. This time it was 3/4 of the way thought the FINAL cut and it took off home and broke the bit, then returned back and tried to start back where it left off. Said G?1 ******* on the screen. A few times it just hickuped in the cut. hung for a second then went back to work. No idea why its doing it and I’ve never had a cut do that before. Checked the gcode and everything seems like it should. That’s it I’m done messing around. Tomorrow morning the jackpot gets installed and we will see how it goes finishing the cut out. I have no doubts it will go well!

I had mine just deciding to go at full speed, even more than I had put in, in a straight line. I restarted the cut, happened again. Then it slowed down to a crawl. After all it was the ESP32 that hada hiccup. Restarting it completely fixed it.

Hello @Jonathjon - would you be able to share some photos of your mist system?

In addition to the photo from above, I’m looking for some detail as to how you have mounted the valve body to your core, how you have mounted the IPA bottle to the gantry, and how you have routed the air and liquid hoses.

Also do you have any feedback/recommendations on which mister you are using? I am looking at this one, which seems somewhat similar to the one that you have .

I am unfortunately still at work but will be home the end of this week and try to get you some more pictures.

For the mount I’m using @DougJoseph kinematic mount and he has a mount specifically for the air mister that I am using.

For the hoses I have compressed air run through pex all over my garage. Overhead where my dust collection comes off of the wall to run accross to the LR I installed a regulator and a valve. From there I run the 8mm tubing along the dust collection hose all the way to the core.

For the ipa bottle for smaller pieces I just stand it on the table, for longer stuff like struts I just sat the bottle on the back of the x beam on top of the dust collection hose. It’s rides along there just fine

This is the air mist I am using…

Mist Coolant Lubrication Spray… Amazon.com

The tubing…

Utah Pneumatic 5/16 Or 8mm Air… Amazon.com

The regulator…

PneumaticPlus SAW2000M-N02BG… Amazon.com

Hopefully all of this helps and if you have any other questions just let me know

Fantastic! Many thanks, and thanks also to @DougJoseph (and you say that you feel that you just hack at stuff… I beg to differ!). Looks like I have a kinematic tool mount print job in my near future.

Wood chips and plastic make for big static charges which can cause issues. Running a grounding wire will keep that from happening.